Method for preparing heat dipping tin of plastic sealed axial diode

A technology of axial diodes and diodes, applied in hot-dip plating process, semiconductor/solid-state device manufacturing, coating, etc., can solve the problems of time-consuming and labor-intensive, unfavorable for efficient assembly line production, etc., to improve processing speed, facilitate Flow operation, reliable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: the preparation method of the hot-dip tin of plastic-encapsulated axial diode, comprises the following steps:

[0034] (1) Before the hot-dip tin treatment is performed on the plastic-encapsulated axial diodes that require hot-dip tin treatment, they are firstly treated with degumming and drying, and the residual glue is removed with a degumming solution.

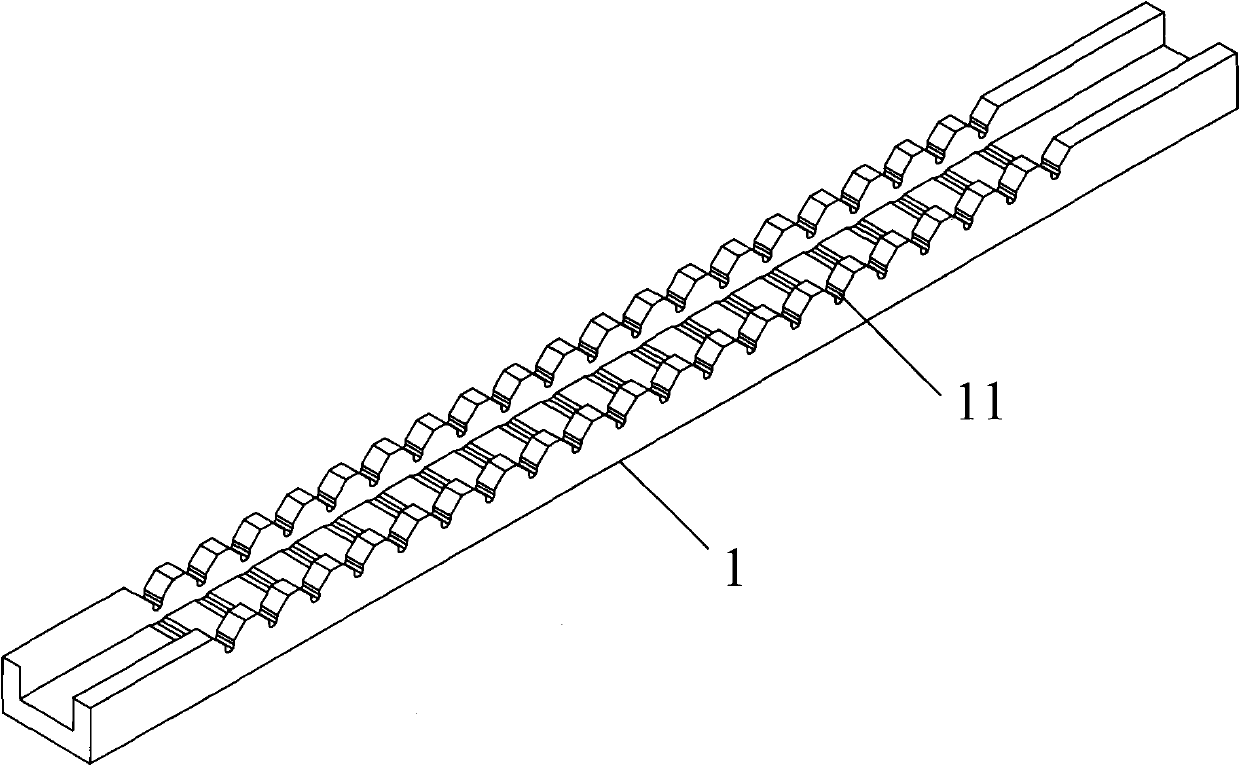

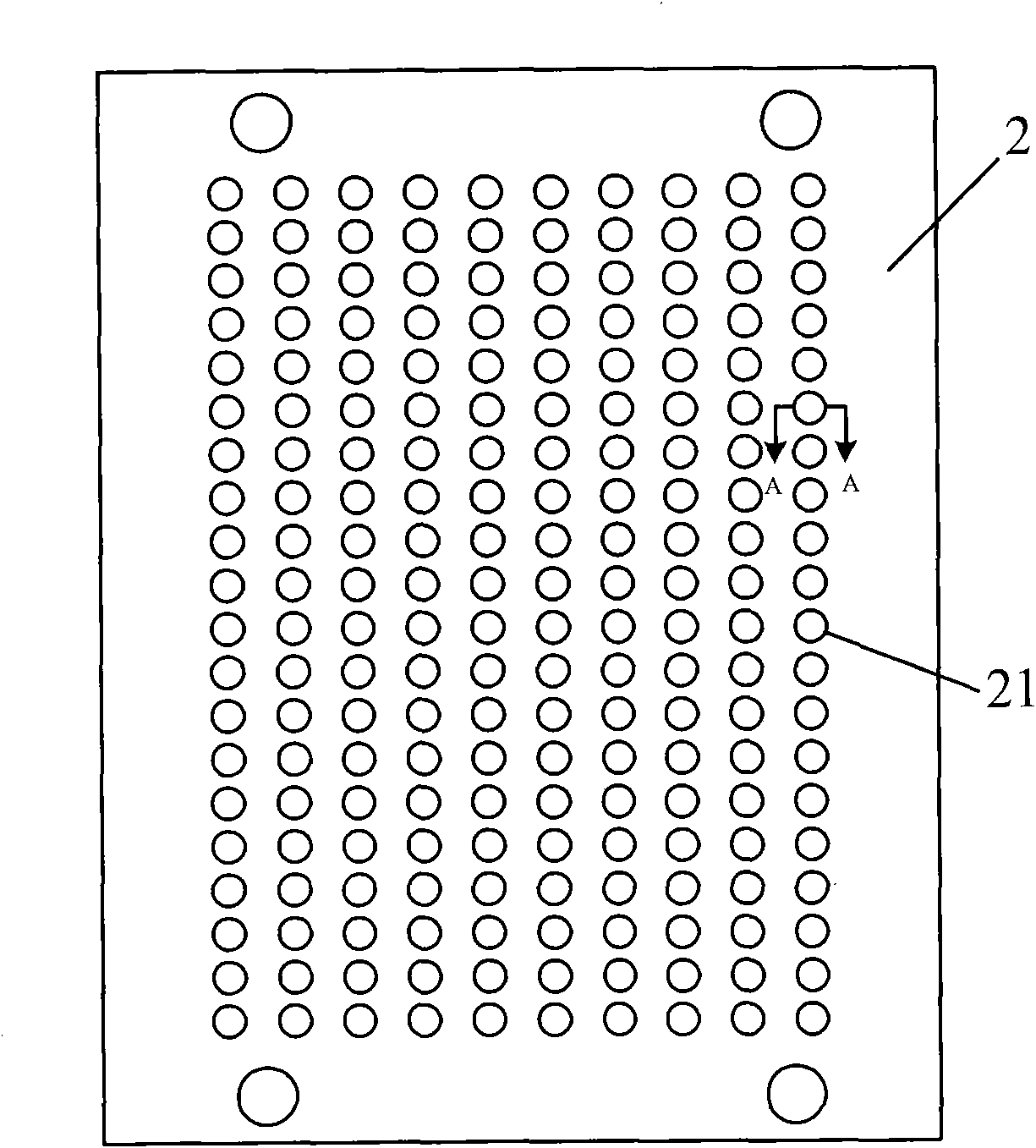

[0035] (2) Straighten the plastic-encapsulated axial diodes that have been processed before degumming and drying through the vibrating basin, the first discharge guide rail, the belt wheel, the chain and the straightening wheel, and then arrange them on the second discharge guide rail in sequence . Specifically: the plastic-encapsulated axial diode is first put into the vibrating basin, and then the diode is dropped into the chain from the vibrating basin through the first discharge guide rail and the belt wheel, and then the plastic-encapsulated axial diode dropped into the chain is guided straight throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com