Lubricating oil

A technology of lubricating oil and base oil, applied in the field of lubricating oil, can solve problems such as engine performance and life impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example is used to illustrate the lubricating oil disclosed in the present invention.

[0025] Add 88.9 parts by weight of base oil, 6.1 parts by weight of dispersant and 5 parts by weight of detergent into a mixer, and mix at 70°C for 90 minutes to prepare lubricating oil A1.

[0026] Wherein, the dispersant used in this embodiment is 3.6 parts by weight of succinimide (T161 produced by Beijing Furunsi Chemical Co., Ltd., with a weight average molecular weight of 800) and 2.5 parts by weight of succinate, and the detergent is 5 parts by weight of calcium salicylate.

[0027] The following performance tests were carried out on the lubricating oil A1 according to the program IIIF engine bench (64h) (ASTM STP 315 I-II) and the program VG engine bench (ASTM STP 315HIII). The test methods and results are shown in Table 1.

[0028] Table 1

[0029]

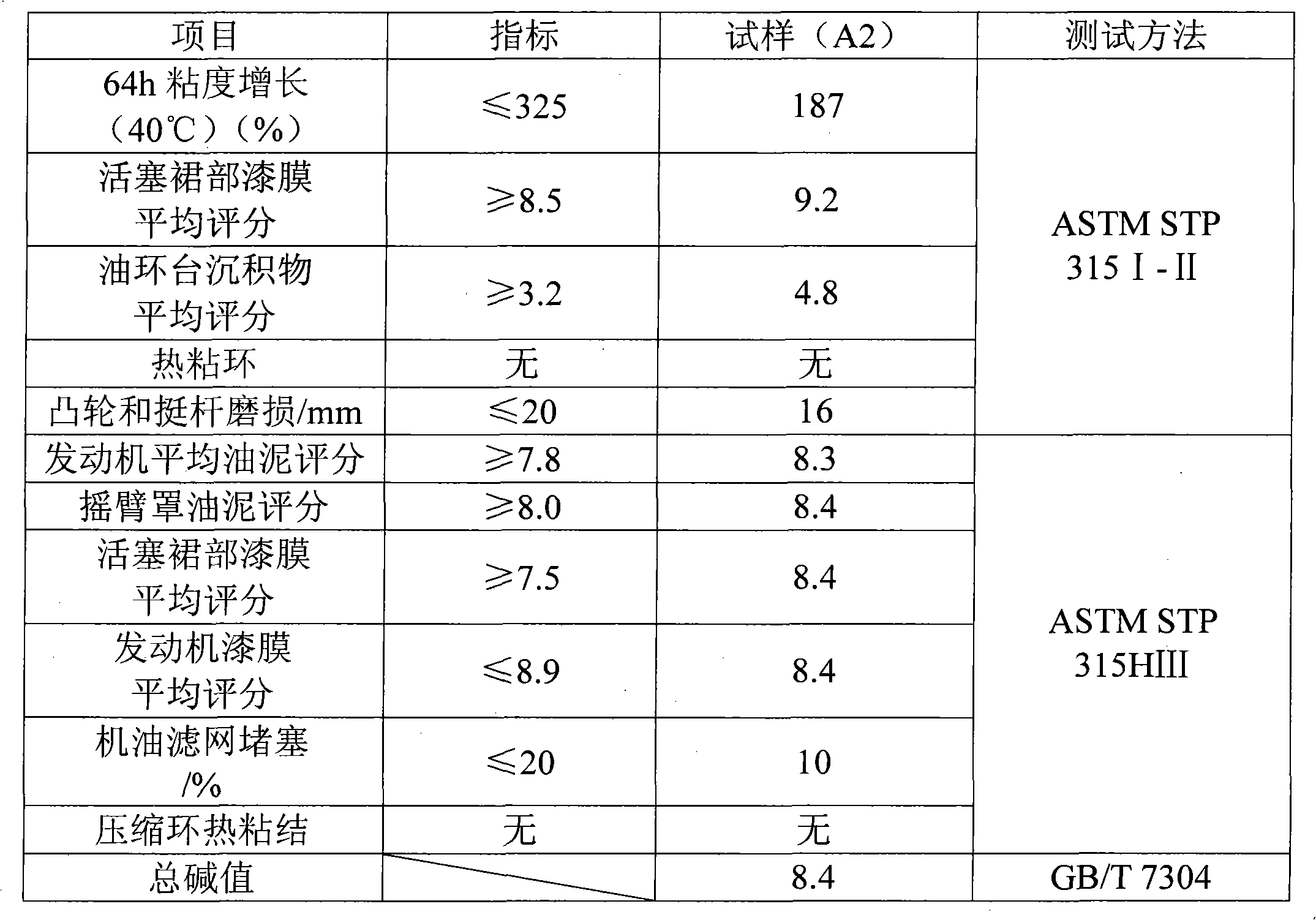

Embodiment 2

[0031] This example is used to illustrate the lubricating oil disclosed in the present invention.

[0032] Add 91.3 parts by weight of base oil, 4.7 parts by weight of dispersant and 4 parts by weight of detergent into the mixer, and mix at 80°C for 90 minutes to prepare lubricating oil A2.

[0033] Among them, the dispersant used in this embodiment is 3.2 parts by weight of succinimide (T161 produced by Beijing Furunsi Chemical Co., Ltd., with a weight average molecular weight of 1500) and 1.5 parts by weight of succinate (Lubrizol The LZ936 produced by Lanlian Additive Co., Ltd. has a weight-average molecular weight of 1000), and the detergent is 1.8 parts by weight of calcium salicylate, 1.2 parts by weight of calcium sulfonate, and 1 part by weight of sulfurized calcium alkylphenate.

[0034] The following performance tests were carried out on the lubricating oil A2 according to the program IIIF engine bench (64h) (ASTM STP 315 I-II) and the program VG engine bench (ASTM S...

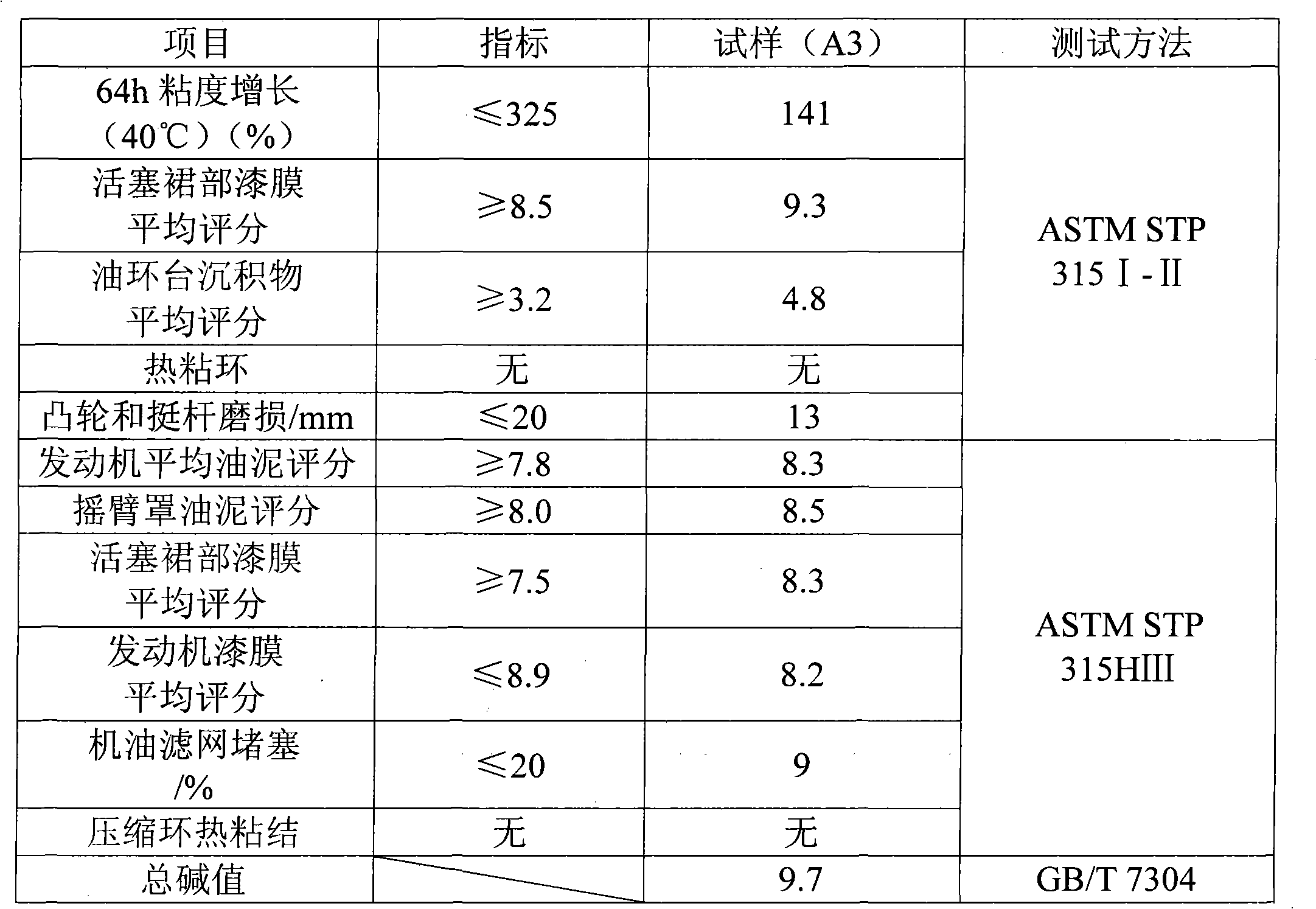

Embodiment 3

[0038] This example is used to illustrate the lubricating oil disclosed in the present invention.

[0039]92.4 parts by weight of base oil, 4.9 parts by weight of dispersant and 2.7 parts by weight of detergent were added into the mixer, and mixed at 80°C for 90 minutes to obtain lubricating oil A3.

[0040] Among them, the dispersant used in this embodiment is 3.6 parts by weight of succinimide (T161 produced by Beijing Furunsi Chemical Co., Ltd., with a weight average molecular weight of 2000) and 1.3 parts by weight of succinate (Lubrizol The LZ936 produced by Lanlian Additive Co., Ltd. has a weight-average molecular weight of 1500), detergent is 1.4 parts by weight of magnesium salicylate with a base value of 300mgKOH / g, 0.8 parts by weight of calcium sulfonate with a base value of 150mgKOH / g, 0.5 parts by weight of A calcium sulfate alkylphenate with a base number of 260 mgKOH / g.

[0041] The following performance tests were carried out on the lubricating oil A3 accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com