Sludge dehydration treatment technology

A treatment process and sludge dewatering technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high solid content in the separation liquid, low solid recovery rate, and unclean filter cloth cleaning, so as to improve the concentration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 The intermittent sludge thickening tank adopted by the present invention

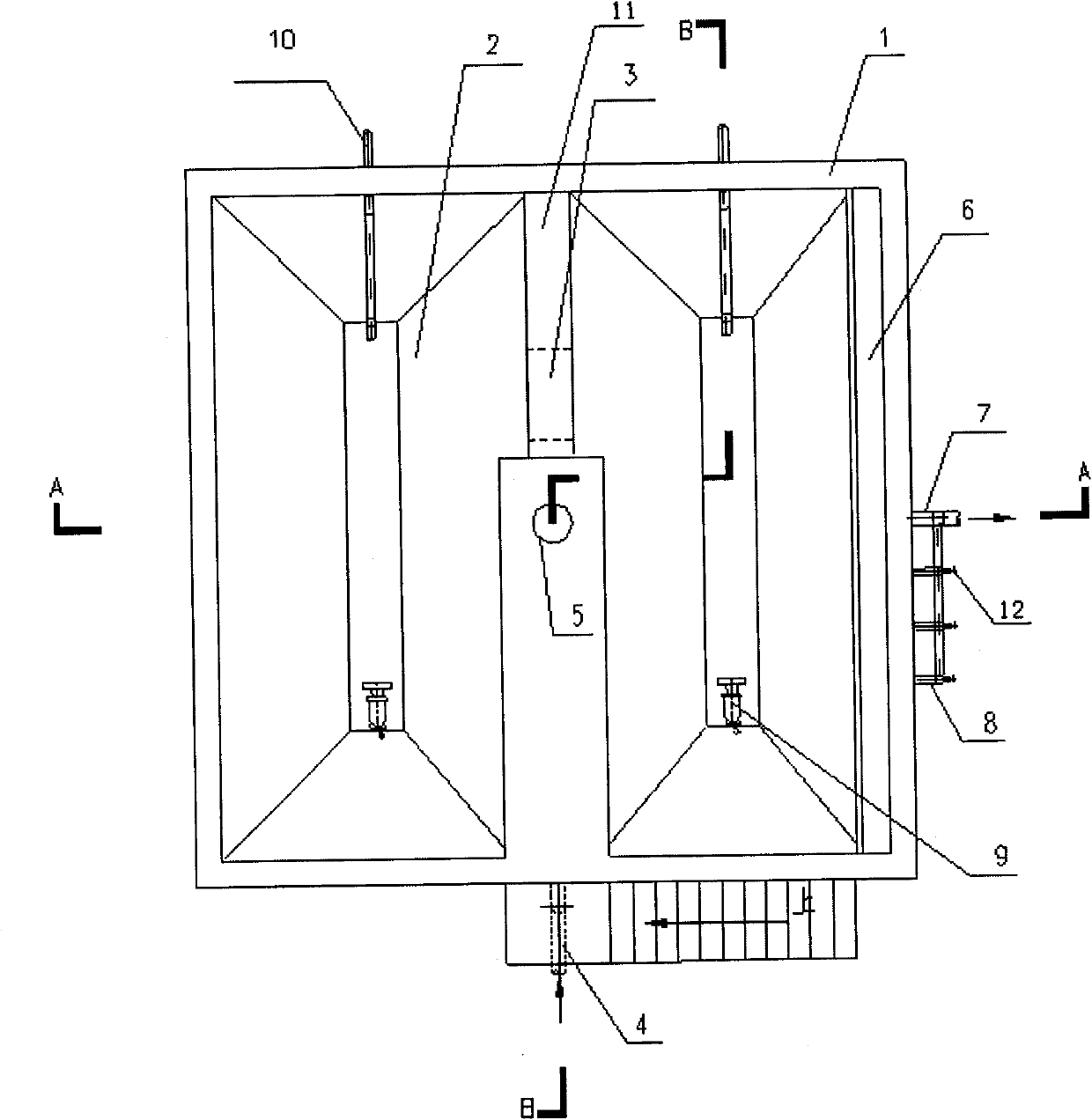

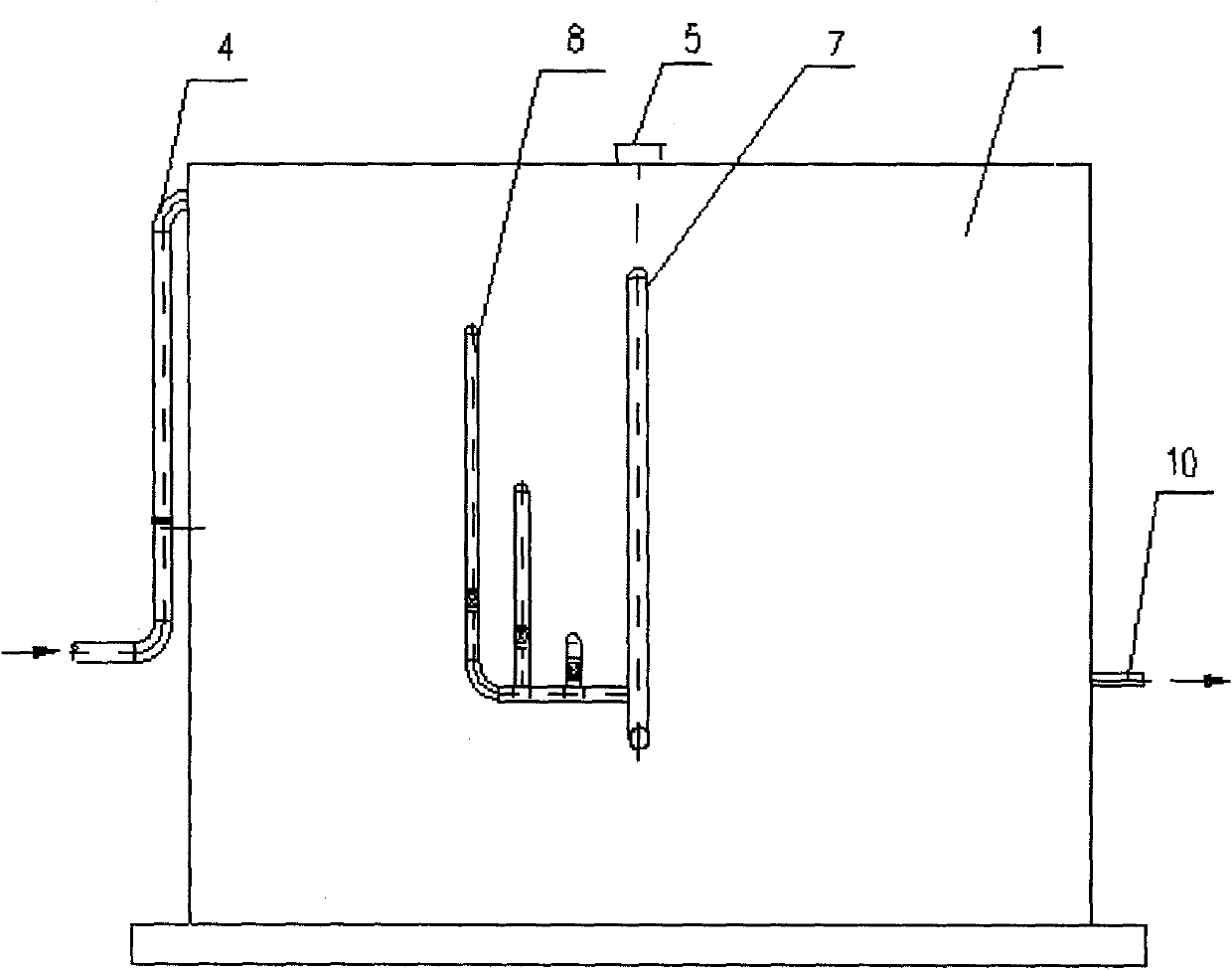

[0039] Such as figure 1 As shown, a kind of intermittent sludge thickening tank capable of uniform discharge of the present invention includes a tank body 1, a sludge bucket 2, a communication port 3, a mud inlet pipe 4, a center pipe 5, an overflow weir 6, a supernatant Liquid drain pipe 8, submersible mixer 9 and mud discharge pipe 10. The designed solid flux of the concentration tank is 60kg / (m 2 .d). The pool body 1 is a reinforced concrete structure of a cube, and its structural size is 9000×9000×6000 (mm); the interior of the pool body 1 is divided into two cuboids by dikes 11, and the ratio of the length (L) and width (H) of the cuboid is L / H=2; the bottom of each cuboid is the sludge bucket 2, so that the bottom of the pool body 1 forms a "W"-shaped double bucket structure, the plane size of the bottom of the single bucket is 1352×6100 (mm), and the four sides of the slud...

Embodiment 2

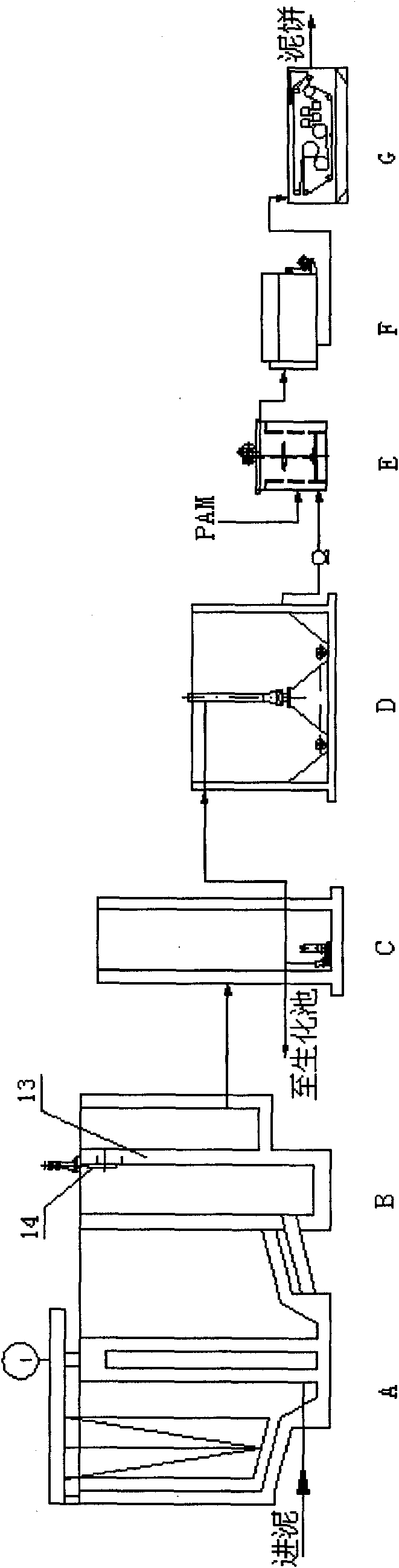

[0046] figure 1 It is a schematic process flow diagram of the present invention. The engineering example involved in the present invention is the sludge three-time concentration + mechanical dehydration treatment process, and the designed residual sludge treatment capacity is 70m 3 / h (not including the sludge return flow part), the water content of the imported sludge of the treatment process is 99.4% to 99.7%, and the continuous gravity concentration tank A involved in this embodiment utilizes the structure of the biochemical secondary settling tank and is placed in the secondary settling tank A sludge discharge control valve is added to the sludge discharge pipeline to ensure that the sludge concentration discharged from the secondary settling tank is controlled within a certain range. The structural size of the continuous gravity concentration pool A is 34×3.6m, the sludge enters the continuous gravity thickening tank A, and after 2-3 hours of thickening, the moisture c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com