Production process of antique engraving wood

A manufacturing process and engraving technology, which is applied in decorative arts, special decorative structures, etc., can solve the problems of insufficient environmental protection and long preparation process, and achieve the effects of short processing time, simple processing technology and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

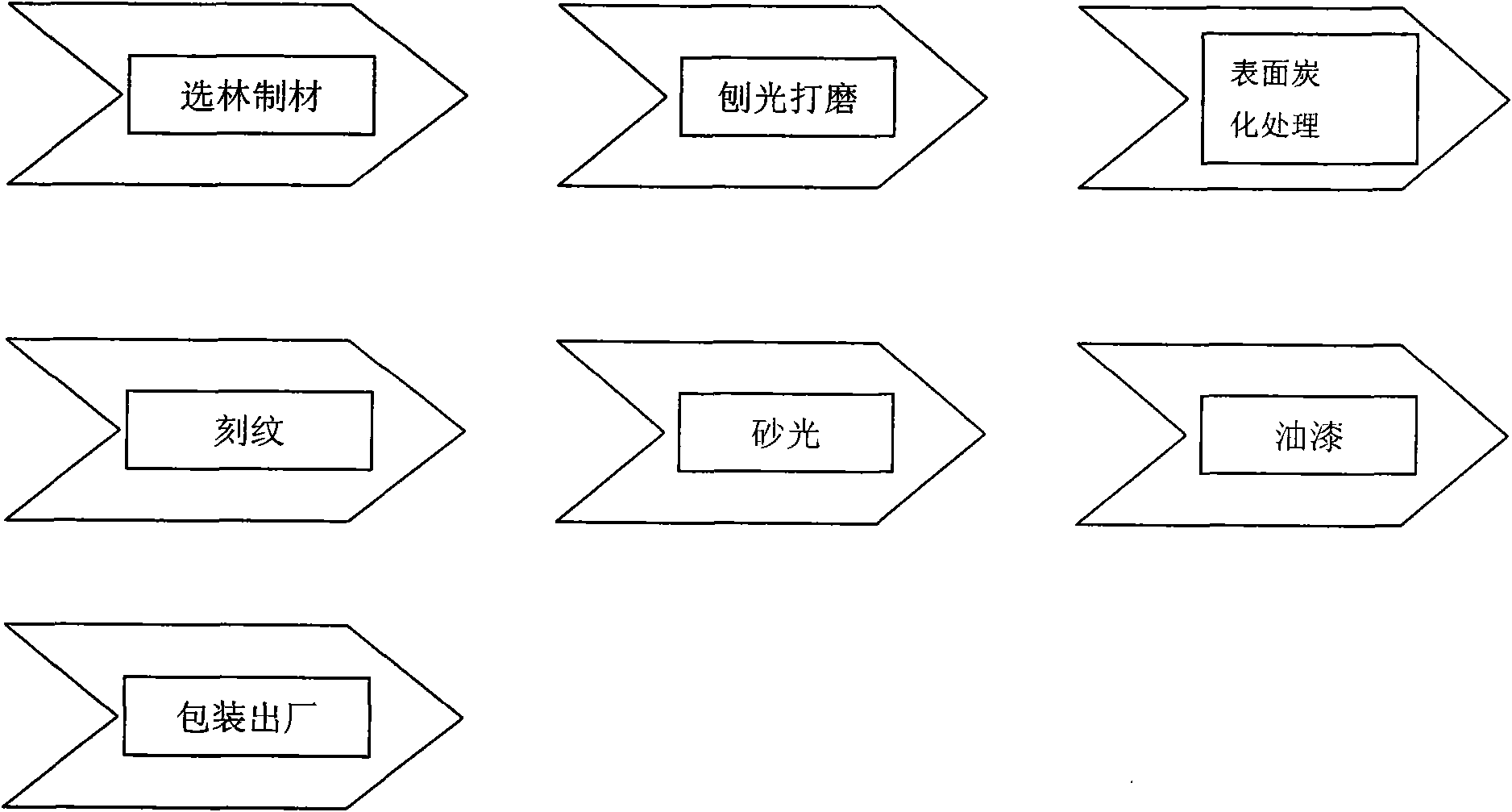

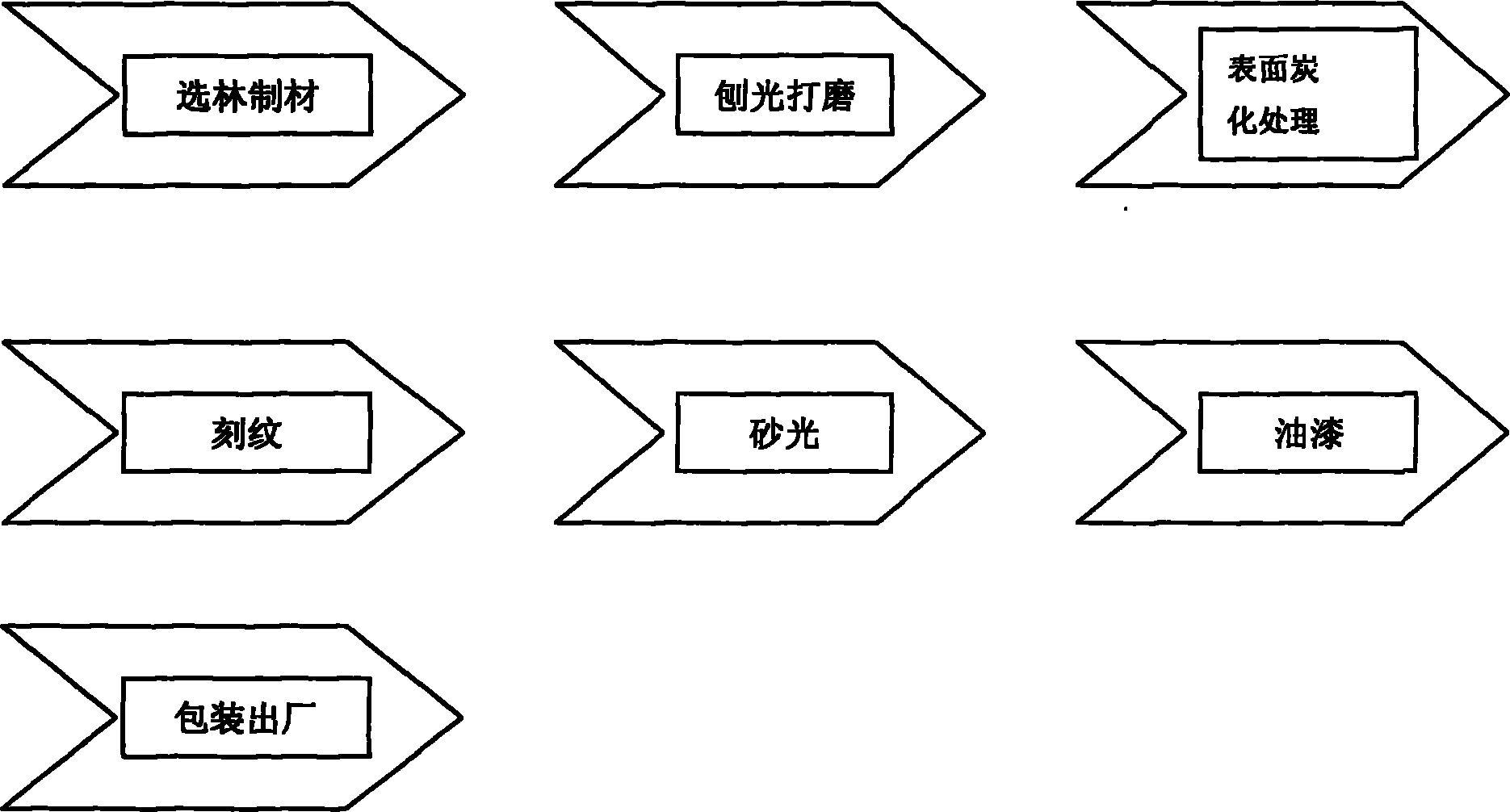

[0030] Example 1 prepares antique carved wood: adopt such as figure 1 The process described in the preparation of engraved wood

[0031] 1) Choose tree species with moderate annual rings, obvious difference between early and late wood, and moderate proportion, and make them into boards of predetermined specifications;

[0032] 2) planing and polishing the board, removing wood thorns and saw marks on the surface of the board, and then chamfering;

[0033] 3) Use an oxyacetylene flame with a temperature above 3000°C to perform surface carbonization treatment on the surface of the planed board under the same conditions until a carbonized layer is formed on the wood surface, and keep the wood surface free from open flames during the treatment process;

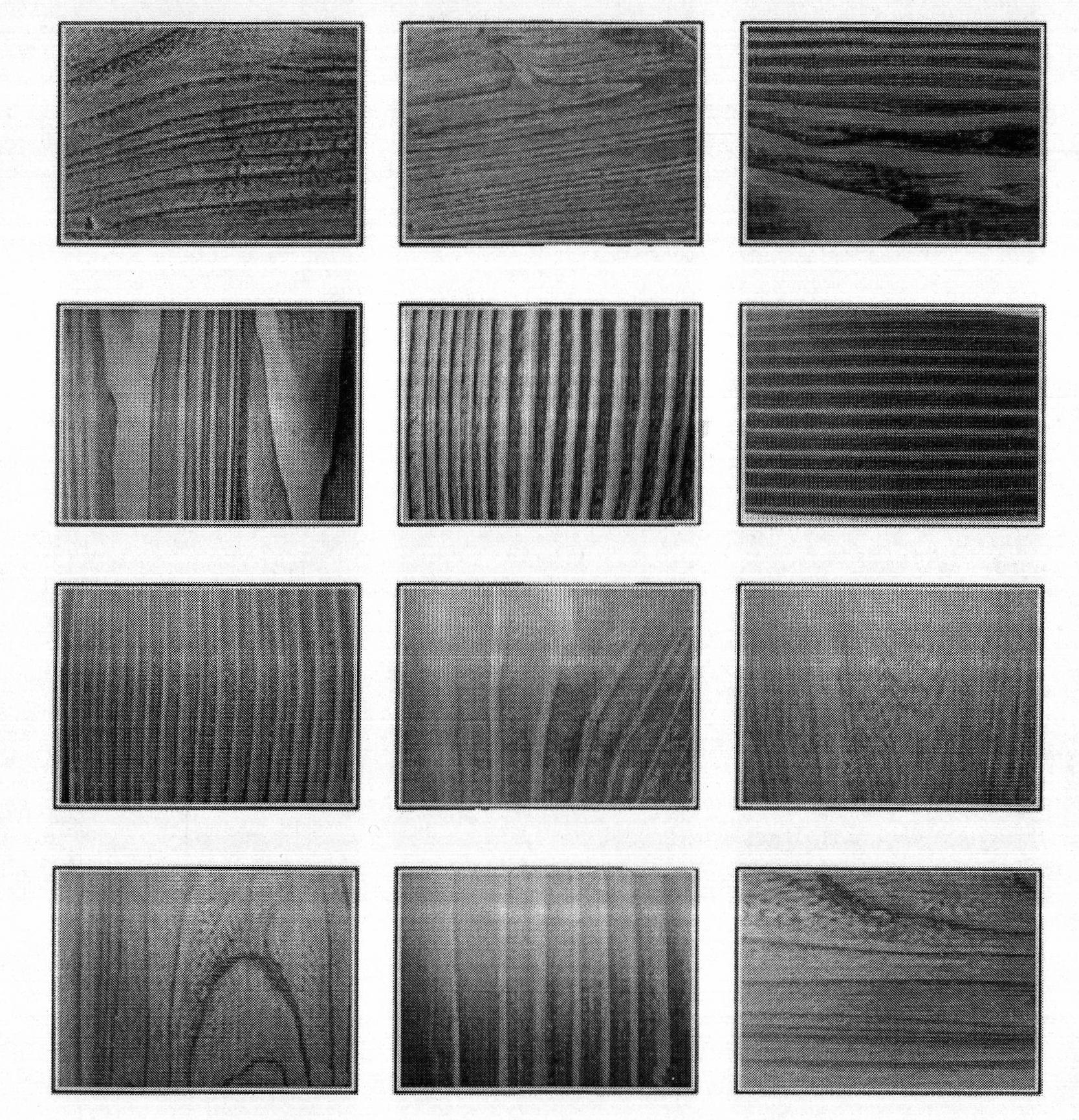

[0034] 4) Use a soft steel wire wheel to polish the wood surface after the surface carbonization treatment, remove the carbonized part of the surface, and highlight the wood texture;

[0035] 5) Polishing treatment step: use 120-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com