Factory artificial seedling method of tilapia

A tilapia and industrialization technology, applied in fish farming, climate change adaptation, application, etc., can solve the problems of insufficient system and comprehensiveness, and achieve the effects of reasonable device design, good economic benefits, and scientific technical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

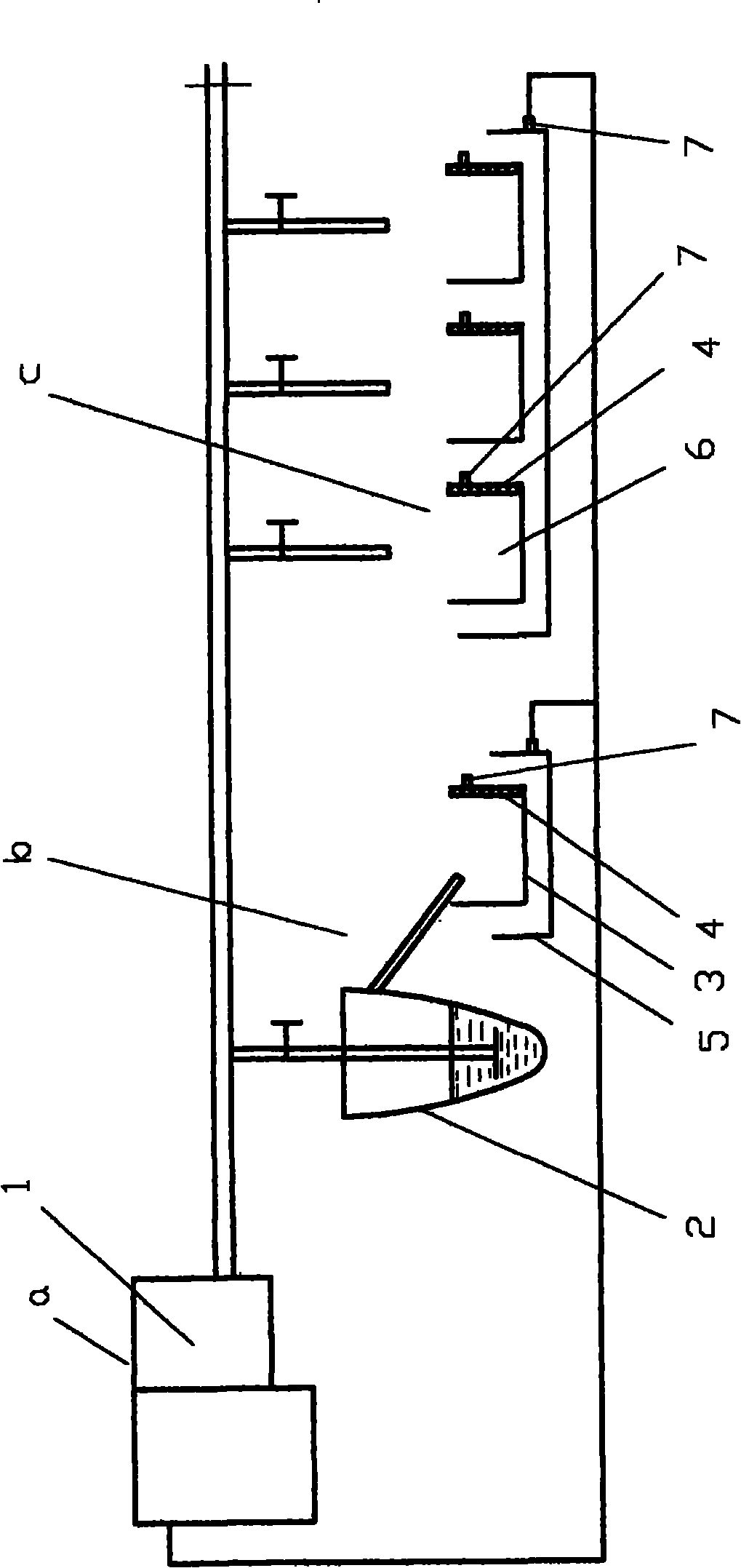

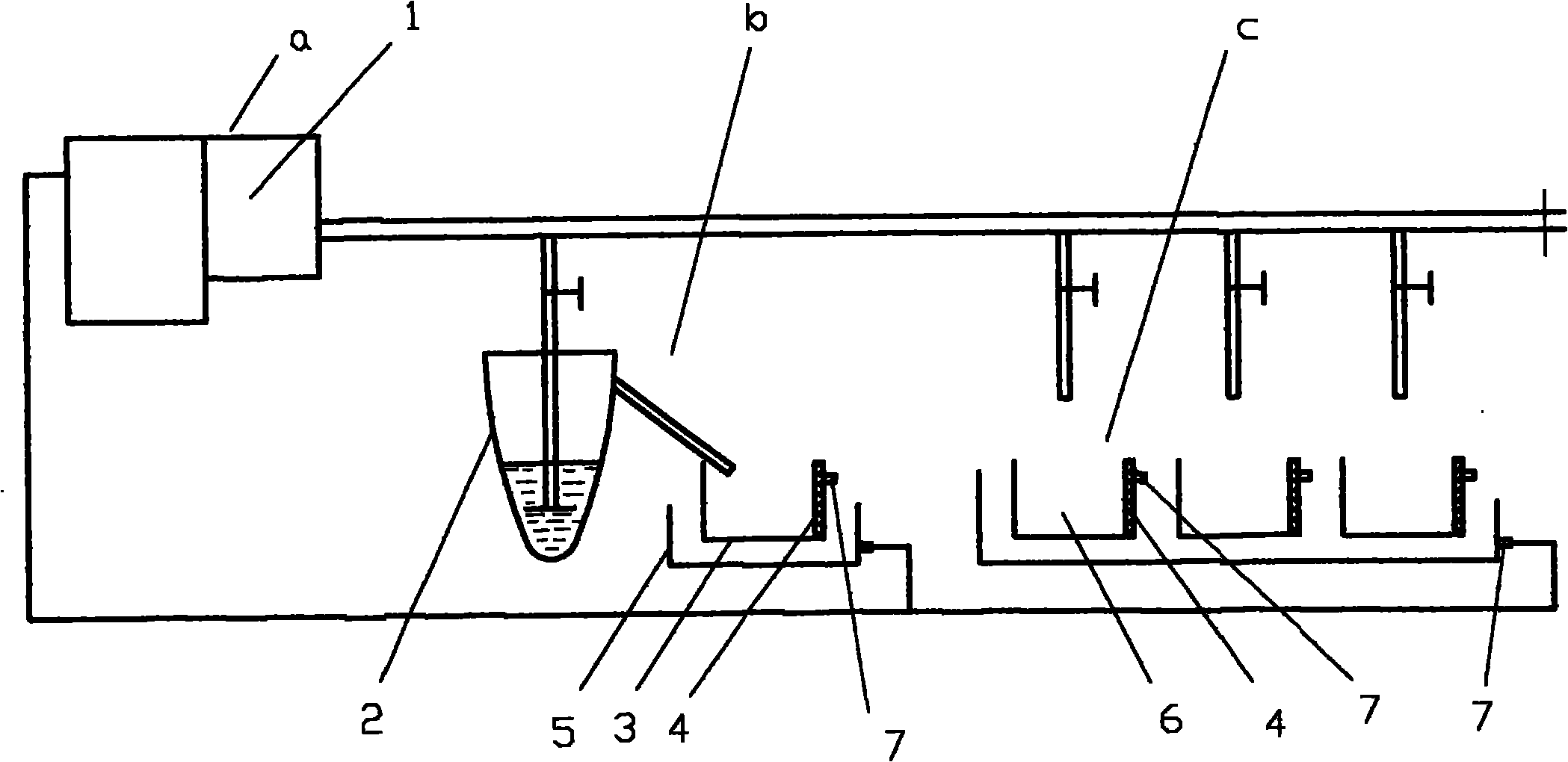

Image

Examples

Embodiment 1

[0015] According to the above process conditions

[0016] 1. The water treated by the filter temperature control device [a] has a temperature of 29°C, a salinity of 8‰, a pH value of 8.3, and a dissolved oxygen content of 5mg / L. Seedling pool device (c) water supply.

[0017] 2. Take 10 portions of tilapia fertilized eggs of 500ml (6000 pieces) by counting with a measuring cup, and place them in 10 hatching buckets [2]. Larvae slowly enter the receiving pond [3] for sex treatment.

[0018] 3. The larvae are sent to the indoor nursery pond [6] on the third day after hatching. When the seedlings are released, the water temperature difference between the nursery pond [6] and the receiving pond [3] shall not exceed ±1°C, and the salinity difference shall not exceed 3‰. Slowly put it into the pond, feed a small amount of rotifers for the first 3 days after the larvae opened their mouths, and gradually increase the feeding amount of rotifers from the fourth day, and the density in...

Embodiment 2

[0020] According to the above process conditions

[0021] 1. The water treated by the filter temperature control device [a] has a temperature of 25°C, a salinity of 5‰, a pH value of 6.5, and a dissolved oxygen content of 5mg / L. Seedling pool device (c) water supply.

[0022] 2. Take 10 parts of 500ml (6000) tilapia fertilized eggs and place them in 10 hatching barrels [2], and incubate with boiling water for 75 hours. The newly hatched larvae enter the receiving pool [3] for gender treatment.

[0023] 3. The larvae are sent to the indoor nursery pond [6] on the third day after hatching. When releasing the seedlings, the water temperature difference between the nursery pond [6] and the receiving pond [3] shall not exceed ±1°C. Slowly put the fry into the pond. After the larvae open their mouths Feed a small amount of rotifers for the first 3 days, then gradually increase the feeding amount of rotifers to 10-15 / ml, cultivate for 18 days to grow to a total length of 3.0cm-4.0cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com