Egg trolley for roadway incubation machine

A roadway type, egg trolley technology, applied in the field of poultry breeding, can solve the problems of inconsistent egg embryo development, large temperature and humidity differences in the egg area, and affect the survival rate of hatching, etc., to achieve consistent development time, concentrated hatching time, and increase hatching The effect of chick rate and healthy chick rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

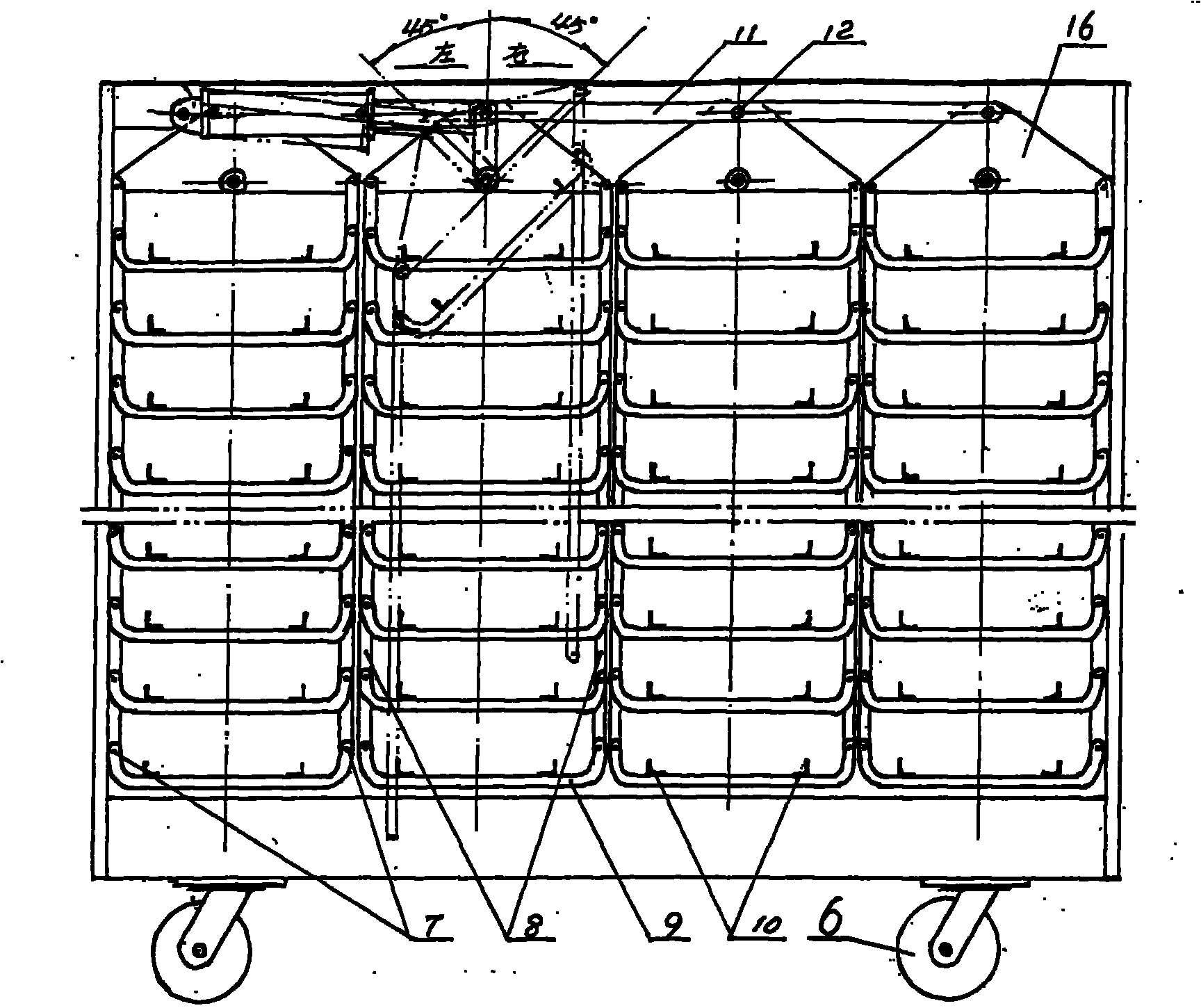

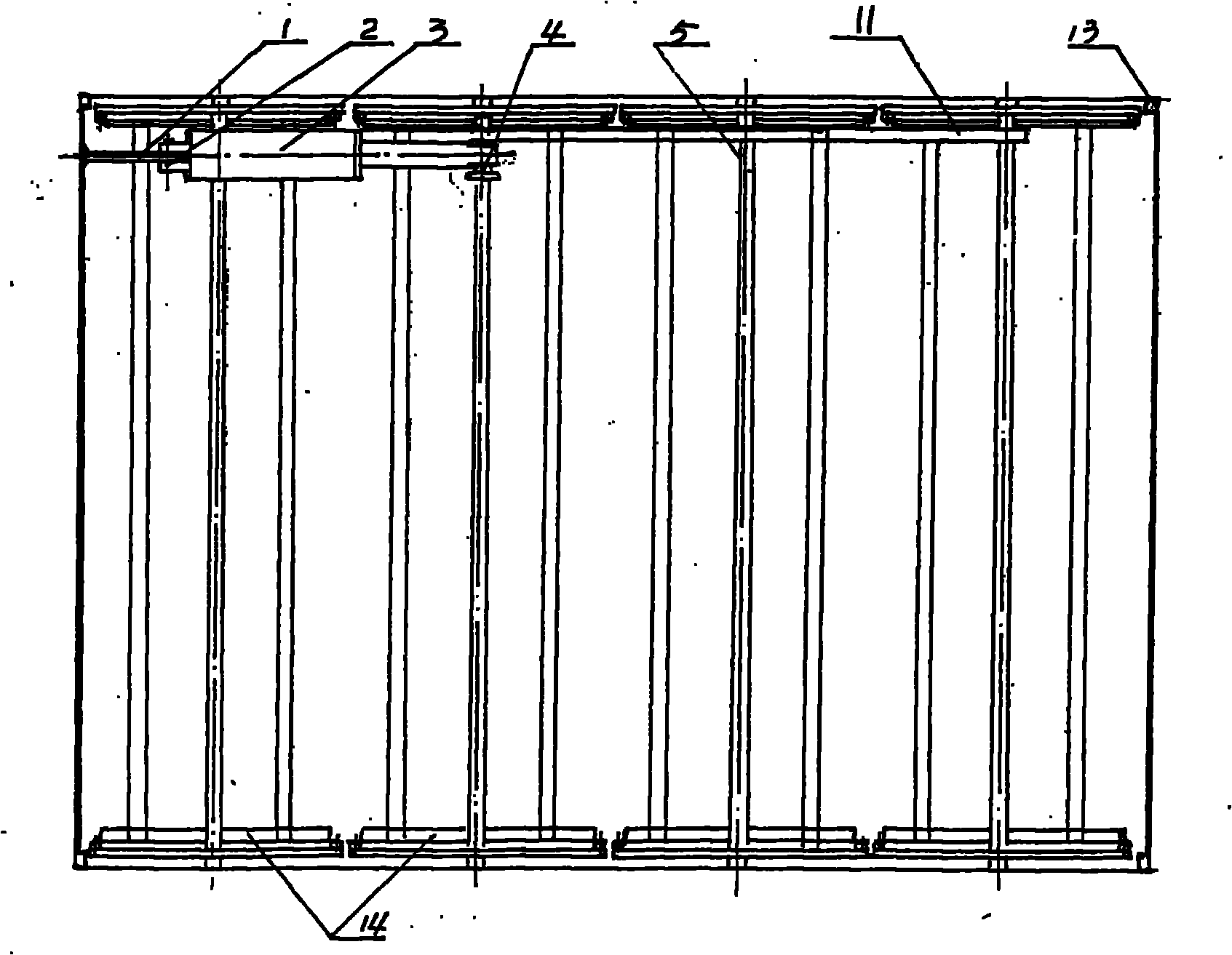

[0016] Embodiment 1: as Figure 1 ~ Figure 2 As shown, the present invention includes a frame 15 with castors and an overturn drive device installed thereon, multiple groups of egg racks, connecting rods 11, pivoting arms 16 and pivoting arm shafts 5, and the frame 15 is that four frame columns 13 pass through angle irons The egg rack consists of a hanger 8, an inner hanger 14, an outer hanger 9 and a slideway 10 for installing egg trays. The egg trays are arranged in layers in the frame 15, and the distance between the upper and lower egg trays is based on The height of the hatching sieve is determined. The rotating arm 16 is a triangular connecting plate. The suspenders 8 of each group of egg racks are connected to the two bottom corners of the rotating arm 16. On the bar 11, each rotating arm 16 is placed on the rotating arm shaft 5, and can swing around its rotating arm shaft 5. The rotating arm shaft 5 is placed on the frame 15 and is parallel to the airflow direction of ...

Embodiment 2

[0020] Embodiment 2: as Figure 1 ~ Figure 2 As shown, the overall structure of this example is the same as that of Embodiment 1, including a frame 15 with casters and an overturn drive device installed thereon, multiple groups of egg racks, rotating arms 16 and rotating arm shafts 5, and each group of egg racks is connected to the On each group of pivoting arms 16, one end of each group of pivoting arms 16 is installed on the connecting rod 11 connected to the turning drive device, each pivoting arm 16 is placed on the pivoting arm shaft 5, and can swing around its pivoting arm shaft 5, The rotating arm shaft 5 is placed on the frame 15 and is parallel to the airflow direction of the incubator. When the rotating arm 16 drives the egg tray on the hanger to turn over, the plane where the egg tray is located is parallel to the airflow direction of the incubator, and is 45° from left to right along the airflow direction. ° swing.

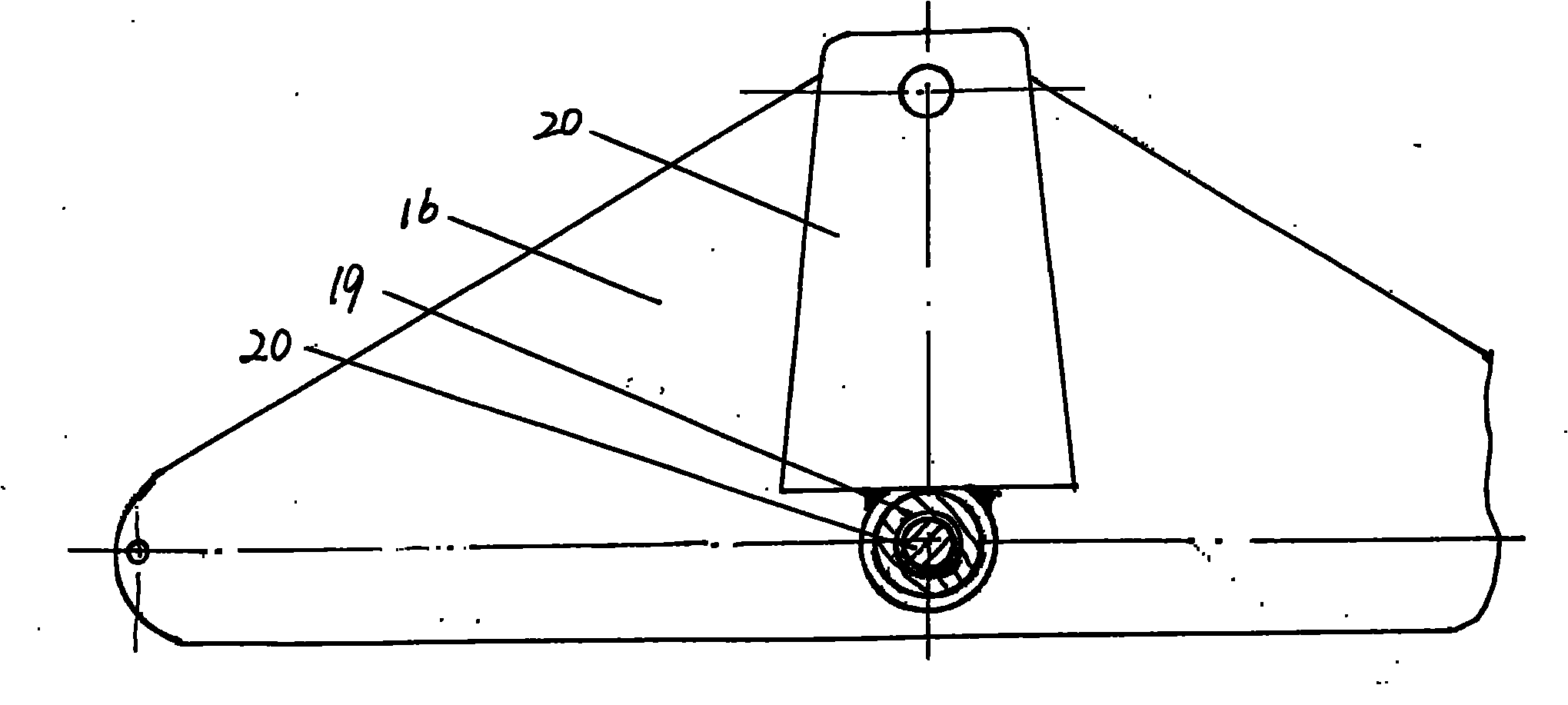

[0021] Such as Figure 3 ~ Figure 5 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com