Seedling-cultivation flexible seeding apparatus

A sowing device and flexible technology, applied in the field of precision sowing devices, can solve problems such as easy seeding, unsatisfactory effect, and seed damage, and achieve the effects of ensuring germination rate, excellent sowing effect, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

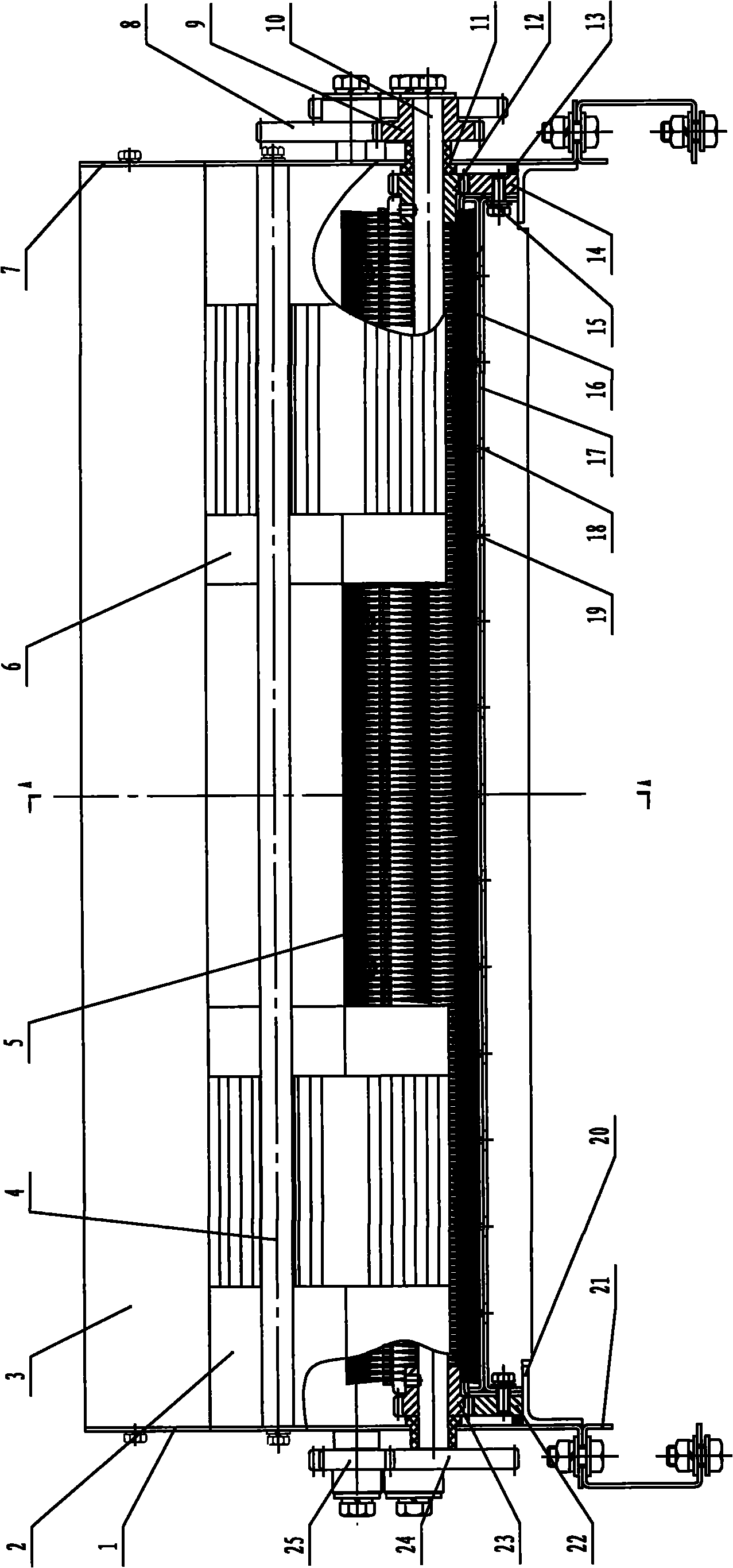

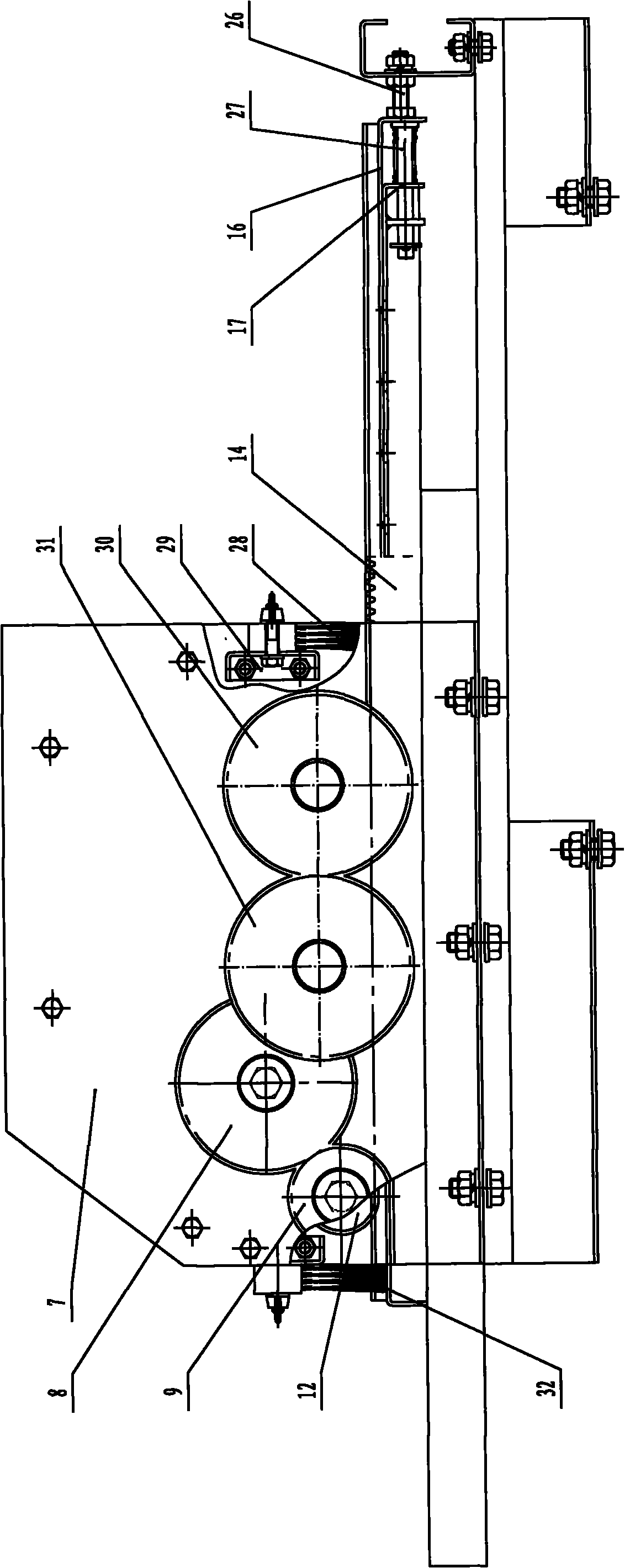

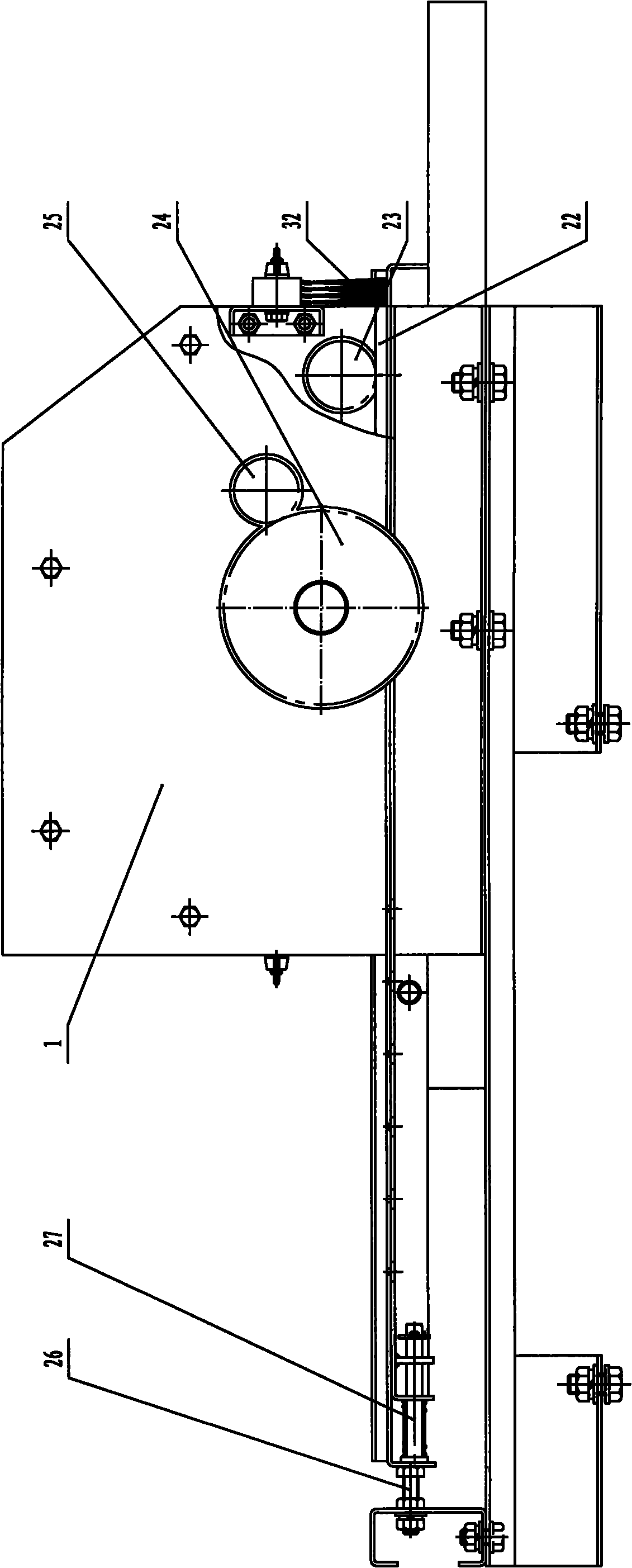

[0022] The left and right beam I 21 and the left and right beam II 20 are respectively fixed on the assembly line frame. The left side plate 1 and the right side plate 7 are fixedly connected with the left and right beams I 21 respectively. The seed-filling brush shafts I and II are horizontally erected between the left side plate 1 and the right side plate 7 through the nylon sleeve 11, and the seed-filling hair brush I 5 and the seed-filling brush II 37 are respectively fixed on the seed-filling brush shaft I , II on. When the filling brush I 5 and the filling brush II 37 were tubular or helical cylinders, the front and rear ends of the left side plate 1 and the right side plate 7 were respectively fixed with a cleaning brush beam 29. Kind hairbrush I 28, cleaning kind hairbrush II 32; Front and rear ends, no need to fix the cleaning brush. The inboard of left side plate 1, right side plate 7 is respectively fixed with motor I 2 and motor II 6 by bolt, and the motor shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com