Big bag filling device capable of preventing bag falling

A filling and big bag technology, which is applied in the field of anti-bag pouring and large bag filling equipment, can solve the problems affecting the filling efficiency of the machine, the rise of the center, and the unavoidable bag dumping phenomenon, so as to avoid the bag dumping problem and improve the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

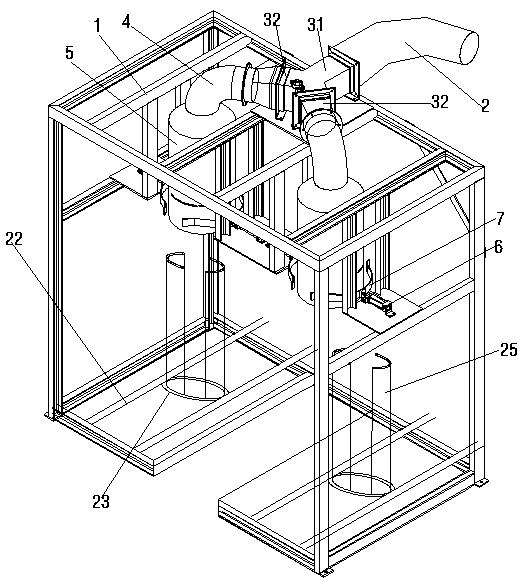

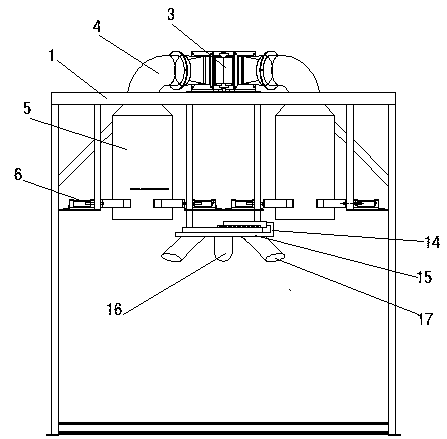

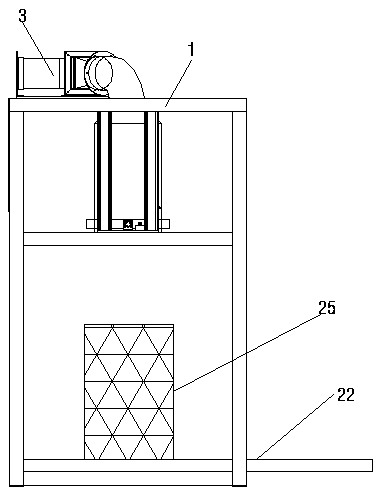

[0032] Refer to attached Figure 1-10 The shown anti-bag filling equipment for large bags includes a filling frame 1 and a material tube 2, the material tube 2 is connected to the opener, and the raw materials unpacked by the opener are transported to the filling device through the material tube 2, and the The top of the filling frame 1 is also provided with a Y-shaped connecting pipe 3, the feed pipe 2 of the Y-shaped connecting pipe 3 is a vertical pipe 31, and the discharge pipe 2 is an inclined pipe 32, and one end of the vertical pipe 31 is connected to the The material pipe 2 is connected, and the other end is connected with the two inclined pipes 32, and each end of the inclined pipe 32 is vertically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com