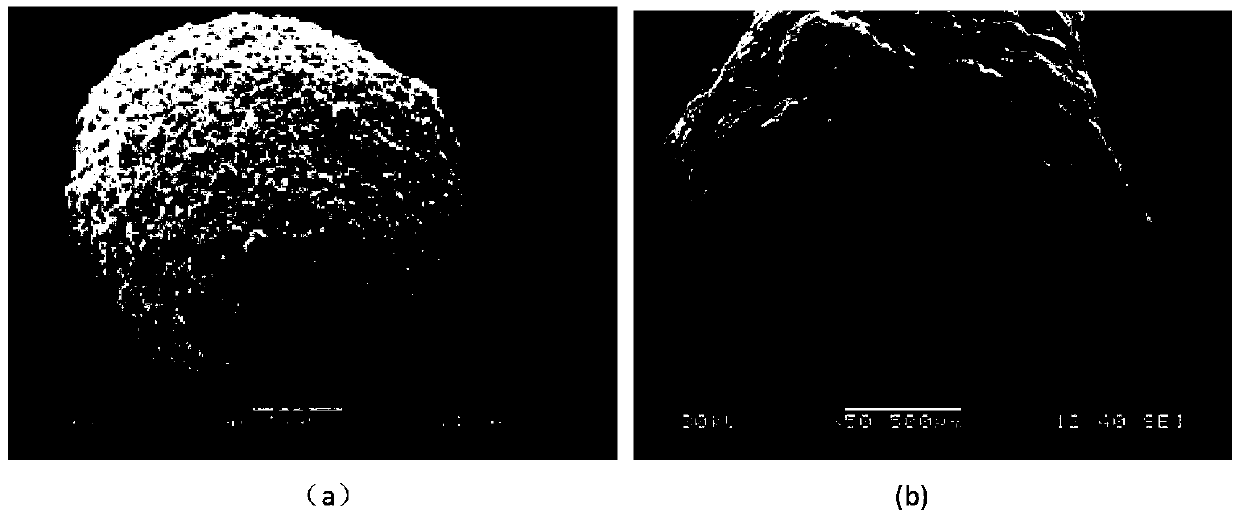

Microporous spherical ammonium nitrate and its preparation method

A granular ammonium nitrate and microporous technology, which is applied in explosives, offensive equipment, explosives processing equipment, etc., can solve the problems of incomplete explosion of ANFO explosives, large critical diameter of ANFO explosives, difficulty in obtaining explosive effect, etc., and achieve detonation High sensitivity, high oil absorption rate, and the effect of improving efficiency and benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

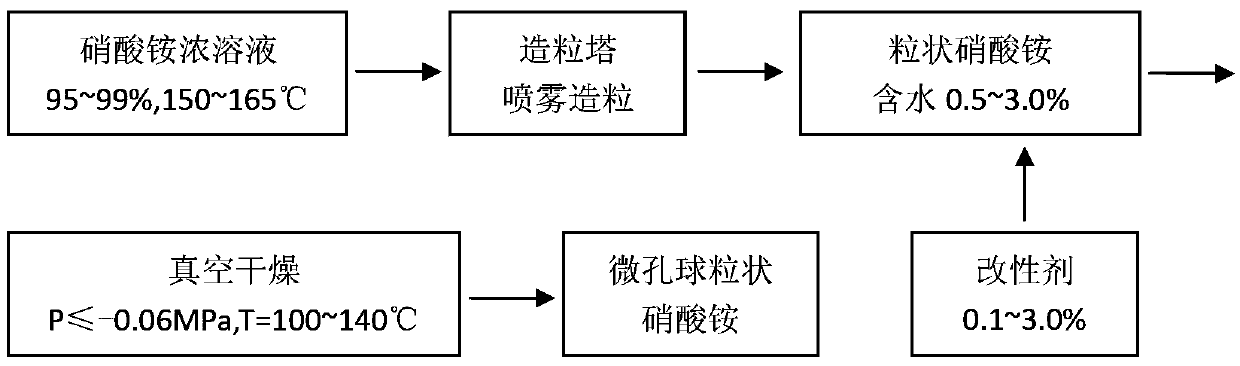

[0033] Embodiment 1 adopts the first technical scheme (spray granulation method) process flow of the present invention such as image 3 : the temperature is 140 ℃, concentration is the ammonium nitrate concentrated solution of 96.0wt% through the nozzle spray granulation that is positioned at the top of the prilling tower, obtains the spherical granular or ellipsoidal ammonium nitrate that contains about 3.0wt% moisture at the bottom of the tower; Then in This ammonium nitrate granule surface evenly sprays 0.05wt% commercially available cationic surfactant octadecylamine acetate and 0.2wt% water-repellent liquid paraffin; This ammonium nitrate is put into the drum granulator again, The temperature inside the machine is controlled at about 140°C, and the pressure is lower than -0.08Mpa; the material stays in the machine for about 5-8 minutes, and it is the product of the present invention after being discharged.

[0034] The measured average bulk density of microporous ammonium...

Embodiment 2

[0035]Embodiment 2 adopts the first technical scheme of the present invention: the ammonium nitrate concentrated solution that is 165 ℃ and concentration is 99.0wt% is sprayed and granulated by the spray nozzle positioned at the top of the prilling tower, and about 0.5wt% moisture is obtained at the bottom of the tower Spherical or ellipsoidal ammonium nitrate; then evenly spray 0.1wt% commercially available cationic surfactant dodecyltrimethylamine on the surface of this ammonium nitrate particle; then put this ammonium nitrate into drum granulation In the machine, the temperature inside the machine is controlled at about 100°C, and the pressure is lower than -0.07Mpa; the material stays in the machine for about 8-10 minutes, and it is the product of the present invention after being discharged.

[0036] The measured average bulk density of microporous ammonium nitrate is 0.71g / cm 2 , The average oil absorption rate is 20.5%; the critical diameter of the MANFO explosive after...

Embodiment 3

[0037] Embodiment 3 adopts the first technical scheme of the present invention: the temperature is 155 ℃, the ammonium nitrate concentrated solution that concentration is 97.5wt% is sprayed and granulated by the nozzle that is positioned at the top of the granulation tower, obtains approximately containing 2.0wt% moisture at the bottom of the tower Spherical or ellipsoidal ammonium nitrate; then evenly spray 0.1wt% commercially available dodecyltrimethylammonium chloride and 0.1wt% nonionic surfactant acrylate on the surface of this ammonium nitrate particle; The ammonium nitrate is put into the rotary drum granulator, the temperature inside the machine is controlled at about 125°C, and the pressure is lower than -0.08Mpa; the material stays in the machine for about 10-12 minutes, and the product of the present invention is obtained after being discharged.

[0038] The measured average bulk density of microporous ammonium nitrate is 0.71g / cm 2 , The average oil absorption rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com