Ultra-multiple parallel-winding wire concentrator for wire winding

A hub and winding technology, applied in the field of hubs, to achieve the effect of ensuring insulation reliability, good wear resistance, and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

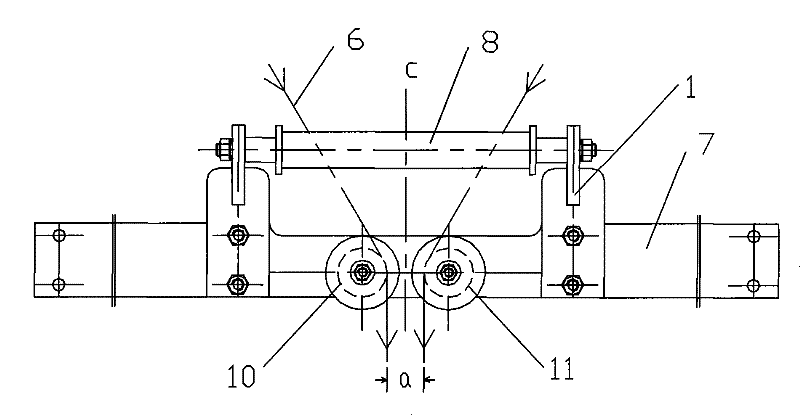

[0018] In the present invention, the plane formed by the axis lines of the third and fourth cylinders 10 and 11 is parallel to the plane formed by the axis lines of the first and second cylinders 8 and 9. Meanwhile, the distance between the third and fourth cylinders 10 and 11 The gap corresponds to the middle part of the gap between the first and second rollers 8,9. see image 3 , image 3 Among them, a is the gap between the third and fourth cylinders 10 and 11, and c is the side centerline of the first cylinder 8 and the second cylinder 9; The middle part of the gap between the rollers 8 and 9 corresponds, that is, the gap a between the third and fourth rollers 10 and 11 corresponds to the side center line c of the first and second rollers 8 and 9 . Therefore, the present invention can effectively prevent the enameled wire 6 from shifting during the pressing process, so that the enameled wire 6 is gradually pressed toward the middle position to form a group of wire bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com