Method for measuring 2-furfural in beer by using high performance liquid chromatography

A high-performance liquid chromatography and beer technology, applied in the field of beer, can solve the problems of low efficiency of enrichment methods and low content of 2-furfural, and achieve the effect of overcoming insufficient retention, high sensitivity and good retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

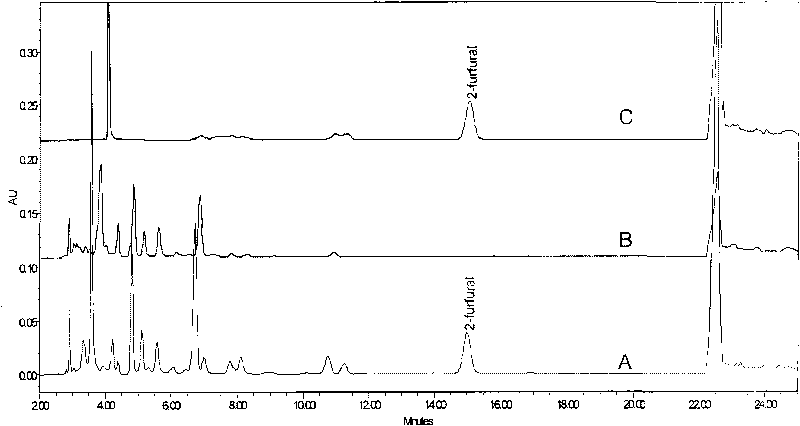

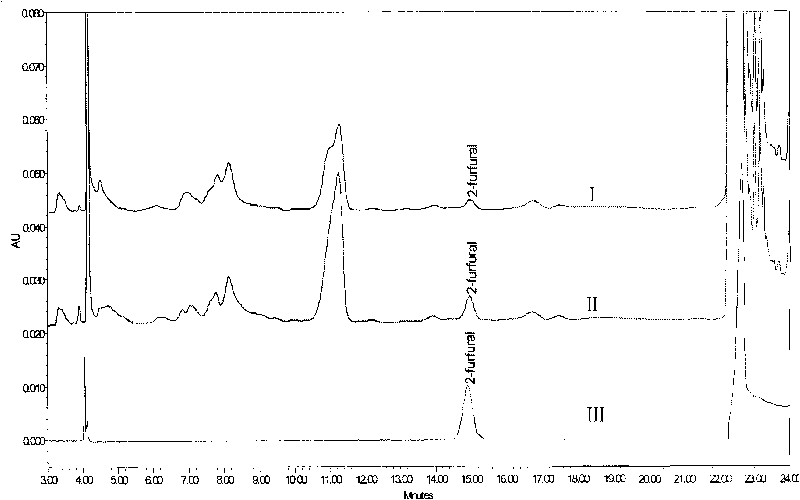

Image

Examples

Embodiment Construction

[0034] (1) Standard sample preparation

[0035] Standard stock solution: Accurately weigh 100 mg of 2-furfural (99%) with a balance, and make it to 100 ml with acetonitrile to obtain 2-furfural stock

[0036] The concentration of liquid is 990mg / L. This solution is stored in the dark at 0-5°C and has a stable period of 3 months.

[0037] Standard working solution: dilute the standard stock solution with acetonitrile to an appropriate ratio, so that the concentration of the 2-furfural standard working solution is 1-2mg / L

[0038] between. This solution is stored in the dark at 0-5°C and is stable for 7 days.

[0039] (2) Pretreatment of beer to be tested

[0040]First pass through the PEP-SPE small column with 5ml acetonitrile, the PEP-SPE solid-phase extraction small column (500mg, 6ml) that Agela Company (Aijieer) (China) provides for the purification and concentration of the beer to be tested adopts, and then use 5ml ultrapure Water is passed through the cartridge to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com