Wiring pattern checking device

A wiring pattern and inspection device technology, which can be used in measurement devices, material analysis by optical means, instruments, etc., and can solve problems such as longer inspection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

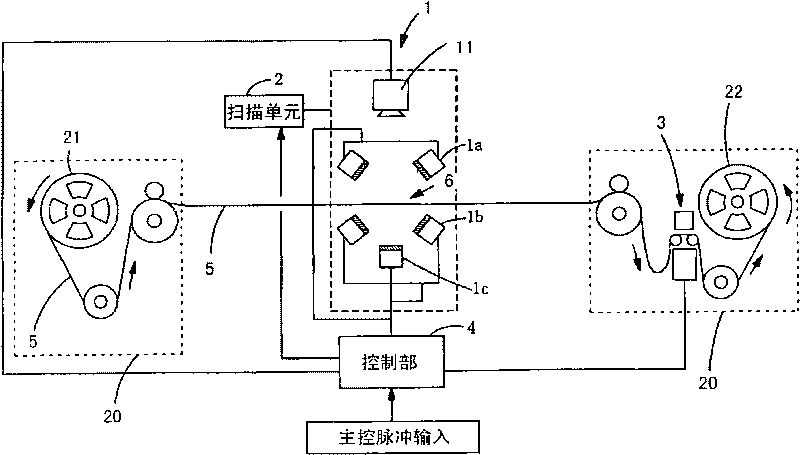

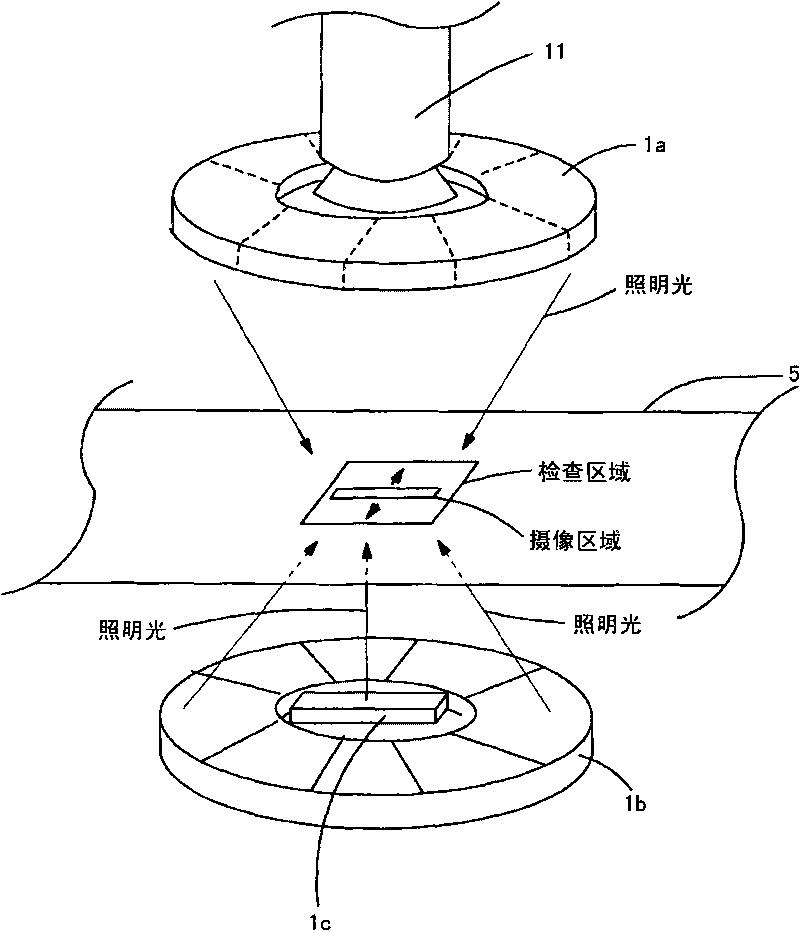

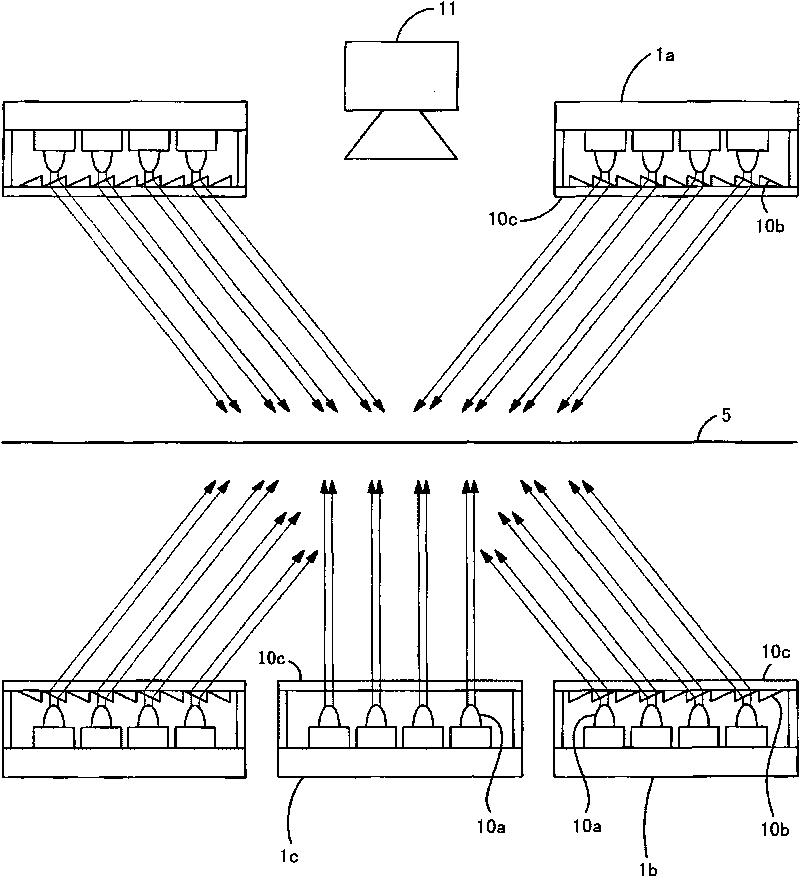

[0035] figure 1 is a block diagram of a wiring pattern inspection device according to an embodiment of the present invention. In addition, the following embodiments are described for the case where the substrate is a so-called TAB tape or COF (Chip On Film) film-shaped workpiece, but the present invention is also applicable to pattern inspection of other substrates with light transmission. .

[0036] As shown in the figure, the pattern inspection device of this embodiment includes: a tape transport mechanism 20 composed of a delivery reel 21 or a take-up reel 22 for conveying the TAB tape 5 , and the TAB tape sent out from the delivery reel 21 5 The inspection unit 1 that irradiates the illumination light and photographs the inspection pattern 6, the scanning unit 2 that scans the inspection unit 1 on the inspection pattern 6 of the TAB tape, and the marking unit 3 that marks the defective pattern.

[0037] The marking part 3 is used to mark the pattern judged as defective ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com