Drive adjusting and loading platform of online detection device

A technology of testing equipment and loading platform, applied in the direction of measuring device, material analysis by optical means, instruments, etc., can solve the problems of full automation and efficiency discount, cumbersome sampling inspection, and inability to effectively complete the whole process of inspection, so as to ensure product quality. The effect of quality, saving human resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

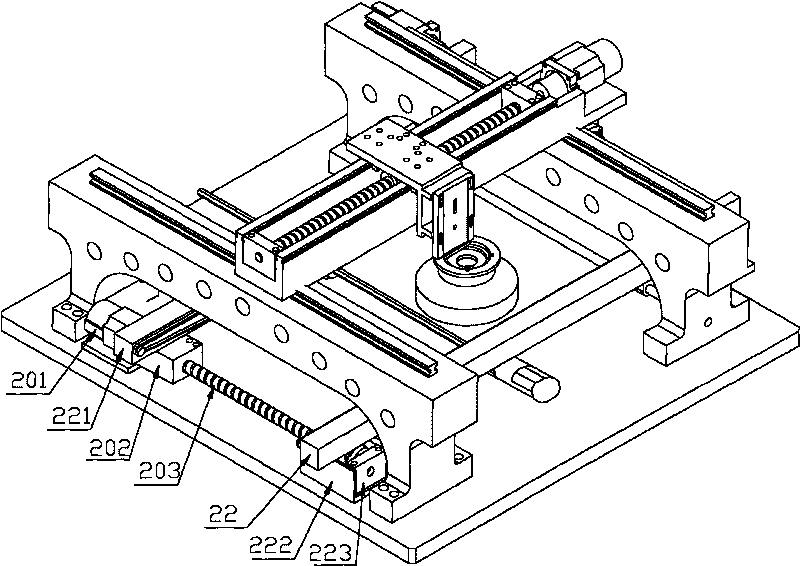

[0015] Such as figure 1 , figure 2 and Figure 4 The transmission and adjustment loading platform of an online detection equipment includes a fixed loading platform 22 and a mobile loading platform 221. One end of the mobile loading platform 221 is connected to the adjustment moving block 202 and the other end is vertically slidingly connected to the support rod 211. The adjustment The moving block 202 is threadedly connected to the adjusting screw rod 203, one end of the adjusting screw rod 203 is connected to the adjusting motor 201 and the other end is connected to the bearing of the fixed block, and one end of the fixed loading platform 22 is fixed on the U-shaped groove 222. One end of the U-shaped groove 222 is fixedly installed with a fixed block 223, and the adjusting screw 203 passes through the mouth of the U-shaped groove 222 and is connected with the bearing of the fixed block 223. A screw bearing 291 is arranged under the middle part of the table 221. The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com