Waterproof test method and waterproof test tank

A box and object technology, applied in the field of waterproof test and waterproof test box, can solve problems such as difficult to determine the pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

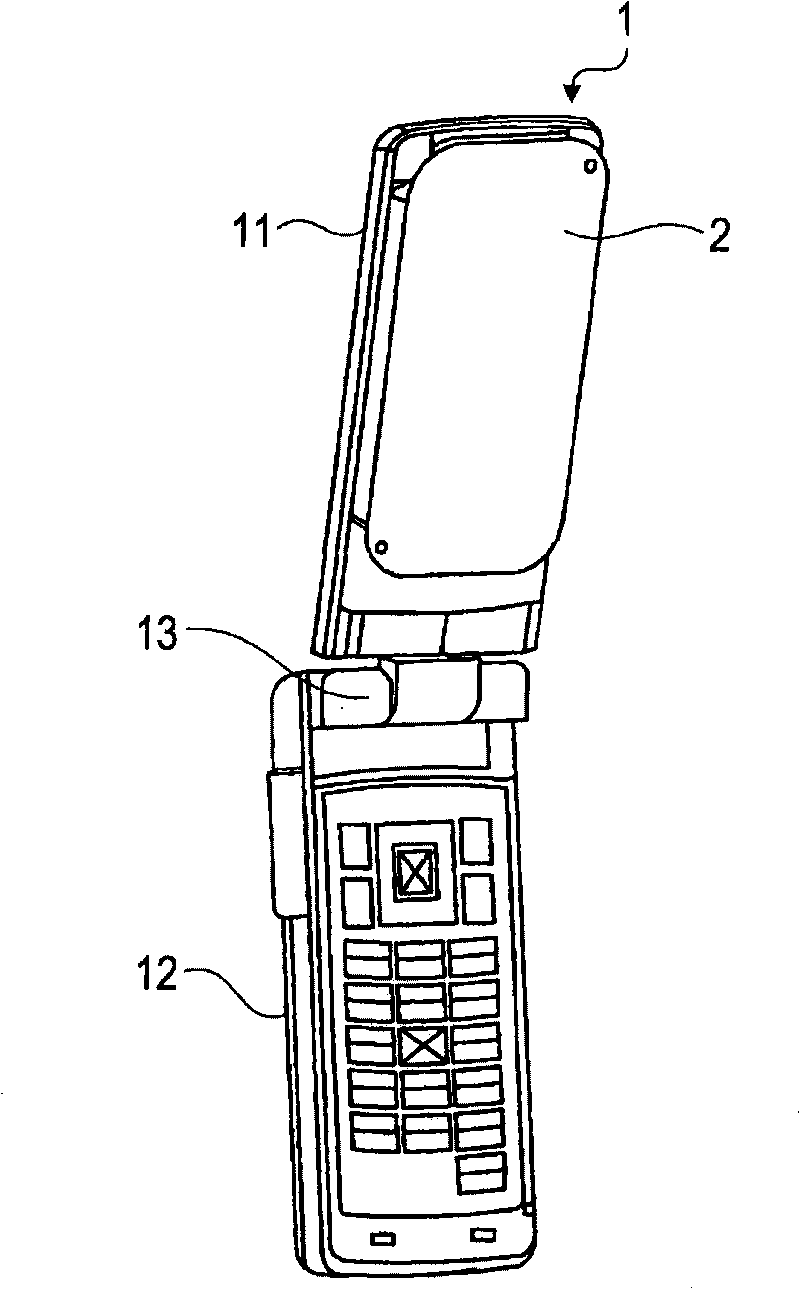

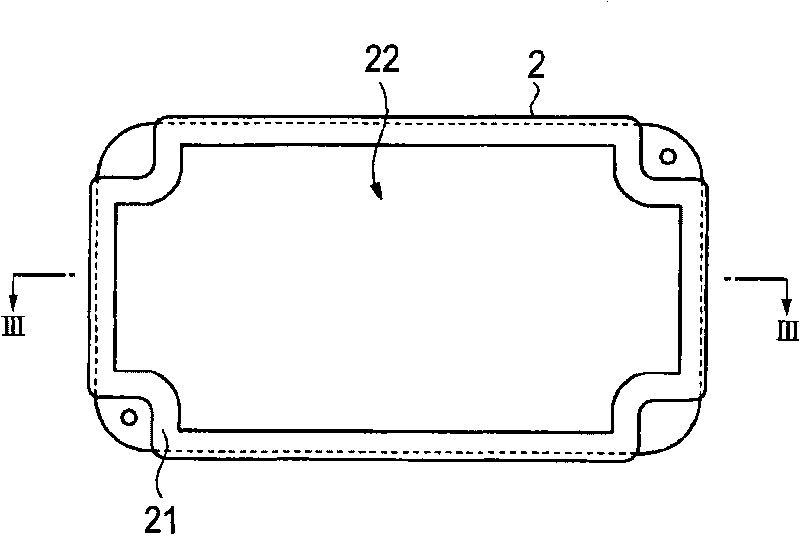

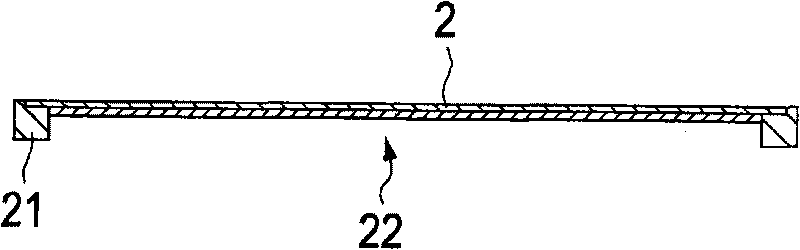

[0021] Hereinafter, one embodiment of a method for testing waterproof properties of an object (airtightness testing method) and a waterproof testing tool disclosed in the present application will be described with reference to the accompanying drawings. Although in the embodiments described below, an example for testing the waterproof characteristics of the movable side case of the mobile terminal device will be described, the application of the waterproof test method and the waterproof test tool disclosed in the present application is not limited by this example .

[0022] An object of the disclosed technology is to provide a water resistance testing method and a water resistance testing tool that enable water resistance to be determined with high accuracy even when the internal volume of a test object is small.

[0023] According to an aspect of the waterproof testing method and waterproof testing tool disclosed in the present application, there is an advantage that airtight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com