Compound steel ball outer cone pulley type stepless speed change concurrent starter

A continuously variable transmission, steel ball technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of no starting function, high pressure of transmission parts, low transmission efficiency, etc. efficiency and productivity, transmission power and transmission efficiency, and the effect of improved driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

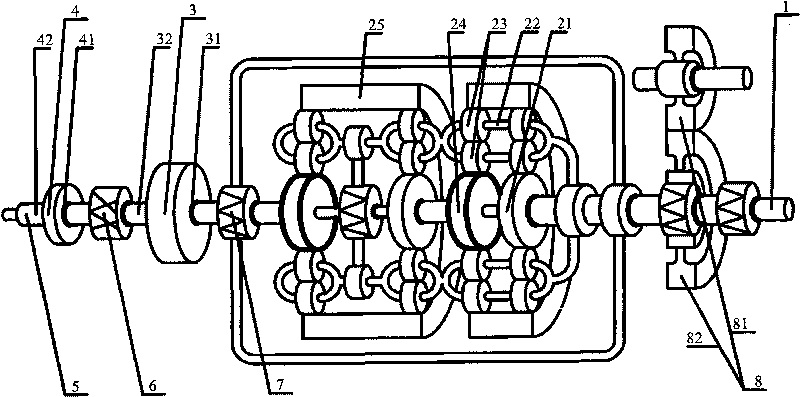

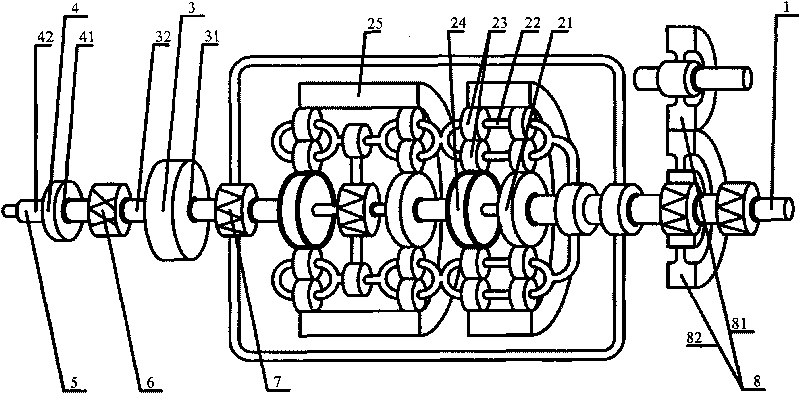

[0019] Such as figure 1 As shown in , a composite type steel ball cone wheel type continuously variable transmission and starter, including input shaft 1, steel ball cone wheel type continuously variable transmission 3, idle and reverse gear mechanism 4, output shaft 5, clutch 6, The one-way clutch 7, the starter gear pair 8, the output end 42 of the neutral and reverse gear mechanism 4 is connected with the output shaft 5, and the input gear 21 and the output planet carrier are arranged between the input shaft 1 and the output shaft 5 22. Planetary gear 23, output gear 24, coupling ring gear 25, the output planet carrier 22 is connected with the corresponding input gear 21, output gear 24 and coupling ring gear 25 through each set of planetary gears 23 on it, the first output The gear 24 is connected with the second input gear 21, and the second output gear 24 is connected with the input end 71 of the one-way clutch 7, the input end 31 of the steel ball bevel wheel type conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com