Separating and recycling device of multiple kinds of chemical liquid medicines

A chemical and liquid medicine technology, which is applied in the field of separation and reuse of various chemical liquids and liquids, and can solve problems such as unusable wafer processing, large amounts of chemical waste liquid, and difficult control of etching precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

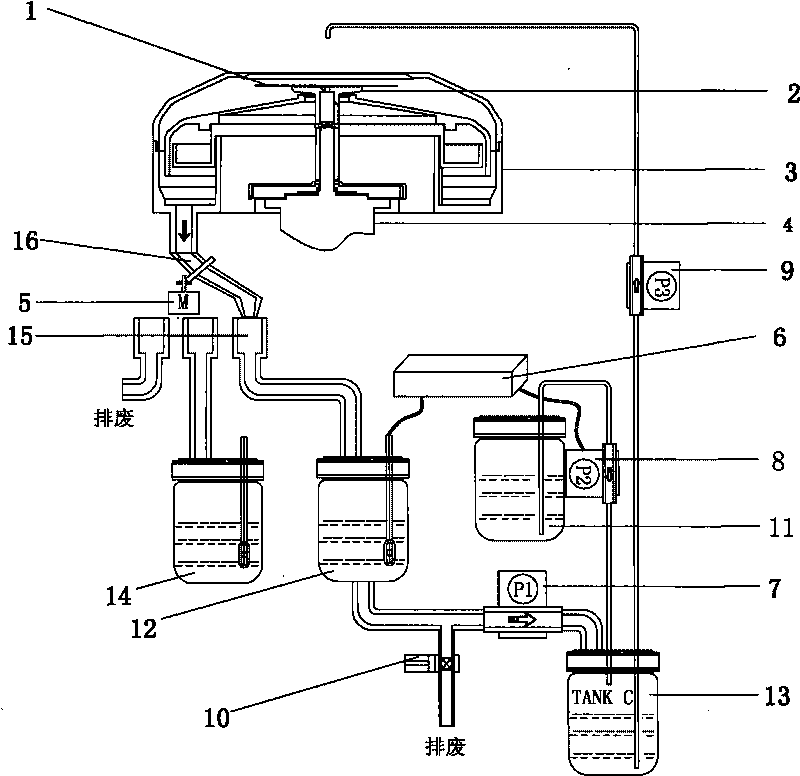

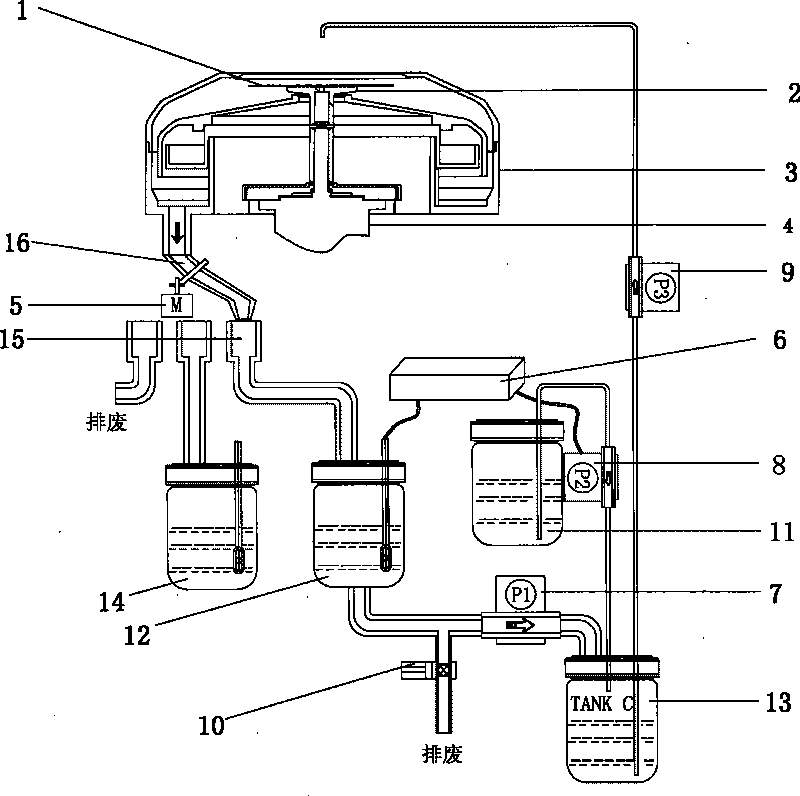

[0016] like figure 1 As shown, the device for separating and reusing various chemicals and liquids of the present invention mainly includes: a wafer 1, a chip holder (CHUCK) 2, a liquid medicine cup (CUP) 3, a rotating motor 4, a guide motor 5, and an acid replenishing controller 6. Pump I 7, pump II 8, pump III 9, waste discharge valve 10, proportioning liquid tank 11, recovery liquid tank B12, regeneration liquid tank 13, recovery liquid tank A14, etc. The specific structure is as follows:

[0017] A rotary motor 4 is arranged inside the liquid medicine cup 3 , the wafer stage 2 is installed on the shaft of the rotary motor 4 , and the wafer 1 is placed on the wafer stage 2 . The guide motor 5 communicates with a section of pipeline 16, the upper end of the pipeline 16 is closely connected with the liquid medicine cup (CUP) 3, and the lower end of the pipeline 16 is rotated by the guide motor 5 in different directions to correspond to the centers of the three collection cups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com