Heat-based high-strength galvanized plate and method for producing same

A production method and technology of galvanized sheet, applied in heat treatment furnace, temperature control, heat treatment equipment and other directions, can solve the problems of increased cost and high production cost, and achieve the effect of reducing production cost, considerable economic benefits, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

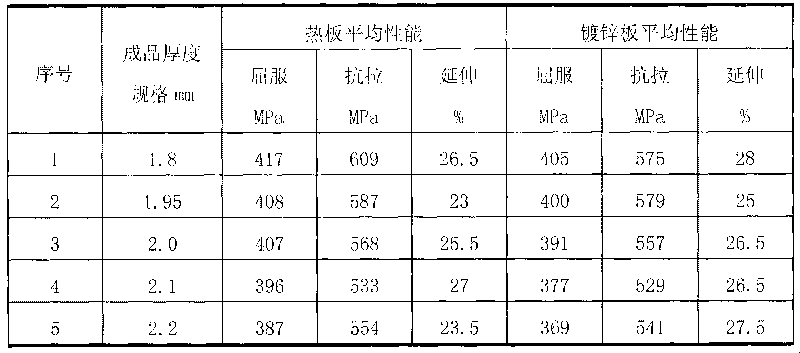

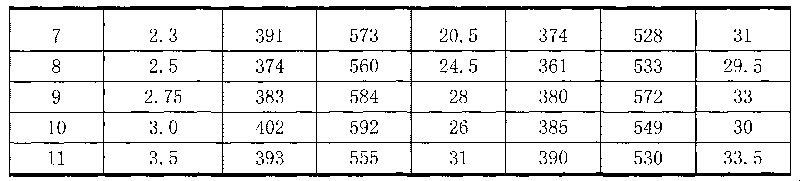

[0019] Example 1: The thickness of the finished heat-based high-strength galvanized sheet is 1.8mm; the chemical composition ratio is as follows: C: 0.18%; Mn: 0.69%; Si: 0.08%; P: 0.014%; S: 0.011%; Als: 0.015 %; Fe: balance.

[0020] Main process and parameters: In the hot rolling process, the heating furnace exit temperature: 1100°C; the final rolling temperature, 830°C; the coiling temperature: 565-584; the rough rolling reduction rate, 45%; in the hot rolling surface cleaning process, The pickling solution is HCl with a concentration of 180g / L; the pickling temperature is 80±2°C; the temperature of the annealing heating section in the galvanizing process: 600°C, the temperature of the annealing reduction section: 630°C, soaking time, 20-25s, dew point ≤ 0°C. The yield strength of the finished product is 375Mpa, the tensile strength is 540Mpa, and the elongation is 31.5%.

Embodiment 2

[0021] Example 2: The thickness of the finished heat-based high-strength galvanized sheet is 2mm; the chemical composition ratio is as follows: C: 0.20%; Mn: 0.80%; Si: 0.04%; P: 0.009%; S: 0.008%; Als: 0.02% ; Fe: margin.

[0022] Main process and parameters: In the hot rolling process, the heating furnace exit temperature: 1110°C; the final rolling temperature, 850°C; the coiling temperature: 560-572°C; the rough rolling reduction rate: 43%; The pickling solution is HCl with a concentration of 180g / L; the pickling temperature is 80±2°C; the annealing heating section temperature in the galvanizing process: 610°C, the annealing reduction section temperature: 635°C, soaking time, 20-25s, dew point ≤ 0°C. The yield strength of the finished product is 395Mpa, the tensile strength is 550Mpa, and the elongation is 34%.

Embodiment 3

[0023] Example 3: The thickness of the finished heat-based high-strength galvanized sheet is 2.3mm; the chemical composition ratio is as follows: C: 0.22%; Mn: 0.65%; Si: 0.11%; P: 0.012%; S: 0.005%; Al s: 0.030%; Fe: balance.

[0024] Main process and parameters: In the hot rolling process, the heating furnace exit temperature: 1120°C; the final rolling temperature, 840°C; the coiling temperature: 565-583; the rough rolling reduction rate: 42%; in the hot rolling surface cleaning process, The pickling solution is HCl with a concentration of 180g / L; the pickling temperature is 80±2°C; the annealing heating section temperature in the galvanizing process: 600°C, the annealing reduction section temperature: 620°C, soaking time, 20-25s, dew point ≤ 0°C. The yield strength of the finished product is 420Mpa, the tensile strength is 595Mpa, and the elongation is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com