Medical cross-linking sodium hyaluronate gel derivative product and preparation method thereof

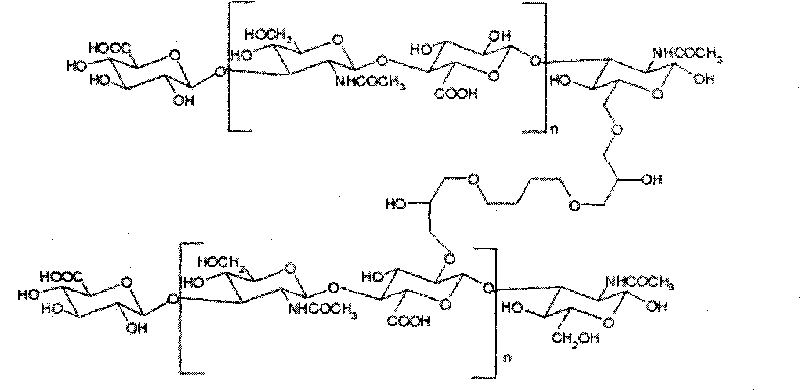

A technology of cross-linked hyaluronic acid and hyaluronic acid, which is applied in the field of medical cross-linked sodium hyaluronate gel derivatives and its preparation, and can solve the problem of reduced viscoelasticity and unsatisfactory maintenance time of cross-linked hyaluronic acid gel , easy to cause inflammatory reactions in the body and other problems, to achieve good tissue compatibility and biodegradability, good effect and durability, and good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 3.3g of hyaluronic acid fine powder with a molecular weight of 2 million Daltons in a container filled with 30ml of 0.25M NaOH solution, and stir and mix for 3 hours;

[0031] During stirring, add 0.3ml of 1,4-butanediol diglycidyl ether (BDDE), and then place the solution in a water bath at 45°C for 5 hours to form a cross-linked hyaluronic acid gel;

[0032] Subsequently, 500 mL of PBS buffer solution with a pH of 7.3 was added, soaked and washed repeatedly for 6 times, and washed for 2.5 days.

[0033] Then put the hyaluronic acid gel in the pressure extrusion device, set the hole diameter to 500 μm, pressurize 7kg / cm 2 , Extrude the hyaluronic acid gel into a microgel.

[0034] Then stir and mix the particulate hyaluronic acid gel and hyaluronic acid to obtain a product, wherein the final concentration of hyaluronic acid is 2 mg / ml. Filling and autoclaving (121° C., 30 minutes).

Embodiment 2

[0036] Put 4g of hyaluronic acid fine powder with a molecular weight of 2 million Daltons in a container containing 30ml of 0.25M NaOH solution, and stir and mix for 4 hours;

[0037] During stirring, add 0.4ml 1,4-butanediol diglycidyl ether (BDDE), and then place the solution in a water bath at 50°C for 5 hours to form a cross-linked hyaluronic acid gel;

[0038] Then add 500mL deionized water to soak and wash repeatedly 8 times, and wash for 3 days.

[0039] Then put the hyaluronic acid gel in the pressure extrusion device, set the hole diameter to 550 μm, pressurize 8kg / cm 2 , Extrude the hyaluronic acid gel into a microgel. Then stir and mix the particulate hyaluronic acid gel with hyaluronic acid, and the final concentration of hyaluronic acid is 2mg / ml. Filling and autoclaving (121° C., 30 minutes).

Embodiment 3

[0041] Put 2.6g of hyaluronic acid fine powder with a molecular weight of 2 million Daltons in a container filled with 30ml of 0.25M NaOH solution, and stir and mix for 4 hours;

[0042] During stirring, add 0.3ml of 1,4-butanediol diglycidyl ether (BDDE), and then place the solution in a water bath at 40°C for 3 hours to form a cross-linked hyaluronic acid gel;

[0043] Then add 500mL deionized water to soak and wash 6 times repeatedly for 2.5 days.

[0044] Then put the hyaluronic acid gel in the pressure extrusion device, set the hole diameter to 550 μm, pressurize 8kg / cm 2 , Extrude the hyaluronic acid gel into a microgel.

[0045] Then stir and mix the particulate hyaluronic acid gel with hyaluronic acid, and the final concentration of hyaluronic acid is 1mg / ml. Filling and autoclaving (121° C., 30 minutes).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com