Method and device for performing flue gas desulfurization by using ammonia process

A flue gas and ammonia method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor crystallization degree of ammonium sulfate, large system resistance, and low oxidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

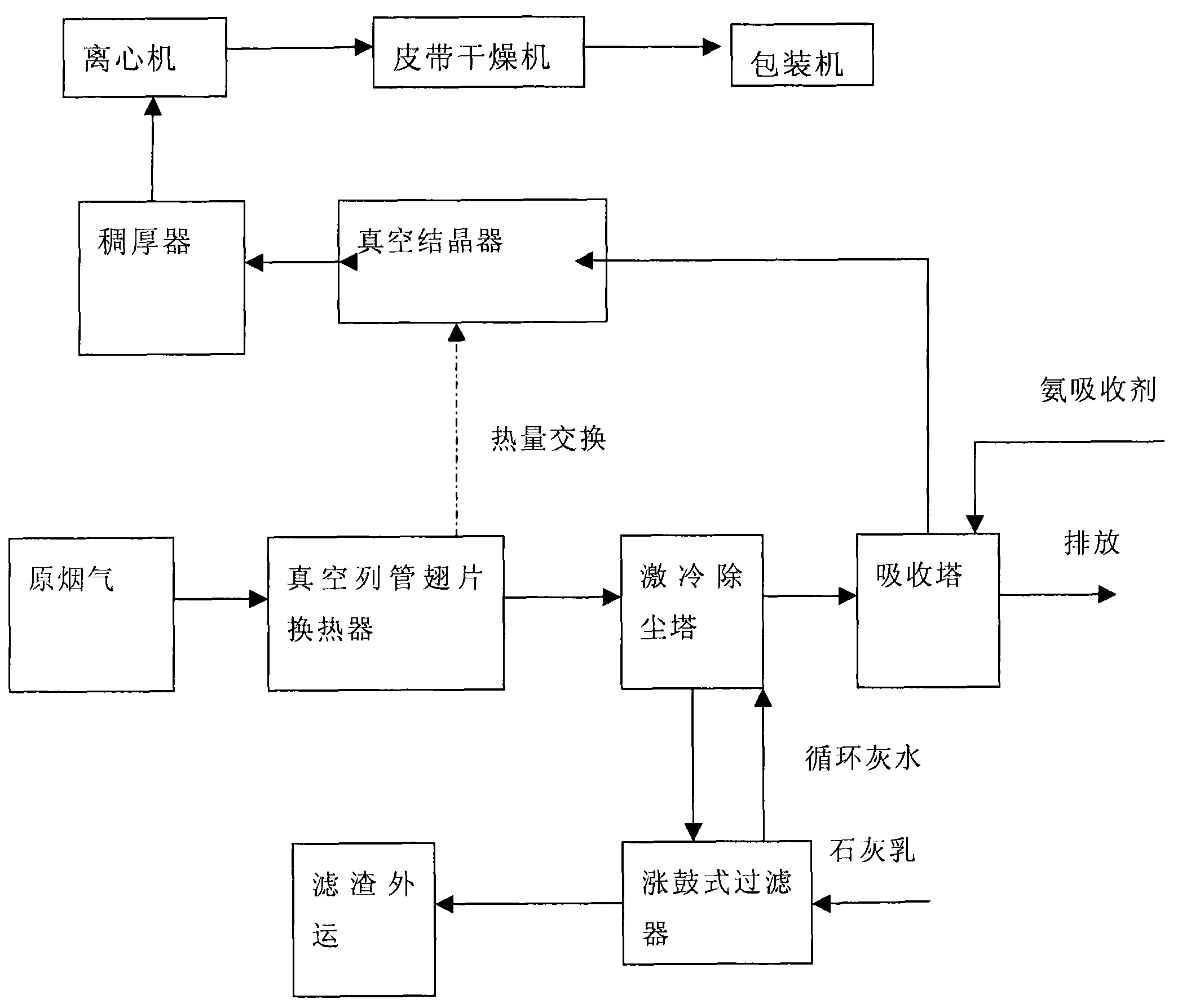

[0074] The flue gas first enters the multifunctional tower for cooling, dedusting and washing to remove a large amount of dust and impurities in the flue gas, and at the same time reduce the temperature of the flue gas to reach the design temperature. During this process, part of the sulfur dioxide is dissolved and turbulent in the circulating fluid. The gray water slurry discharged from the cooling and washing tower passes through the drum filter to filter the particulate matter in the gray water. After filtering, the concentrated gray water containing more particles is added with lime milk to neutralize the pH value, and reacts with the sulfurous acid in it to form sulfurous acid. Calcium is mixed, and the supernatant liquid after sedimentation is reused as supplementary water, and the acid sludge is transported outside, and can be further used after further dehydration.

[0075] The flue gas after chilling and dedusting enters the spray throat of the desulfurization absorpti...

Embodiment approach

[0081] The ammonium sulfate slurry discharged from the absorption tower and concentrated to a certain concentration is sent to the ammonium sulfate liquid tank, and the original high-temperature flue gas is exchanged by the vacuum tube fin heat exchanger, and the water in the tube is in a vacuum state , heated and vaporized upwards to the top vacuum crystallization tank, contacted with cooler ammonium sulfate slurry, released heat and liquefied and returned to the bottom again. Because the vacuum crystallization tank is under vacuum operation, the evaporation temperature of ammonium sulfate is reduced, so the ammonium sulfate slurry starts to boil and evaporate at the reduced temperature. When the inlet flue gas temperature is low enough to provide evaporation heat, low-pressure steam is supplemented.

[0082] The slurry containing ammonium sulfate crystal particles from the vacuum evaporation crystallizer can be settled and concentrated by the thickener, and then sent to the ...

Embodiment 1

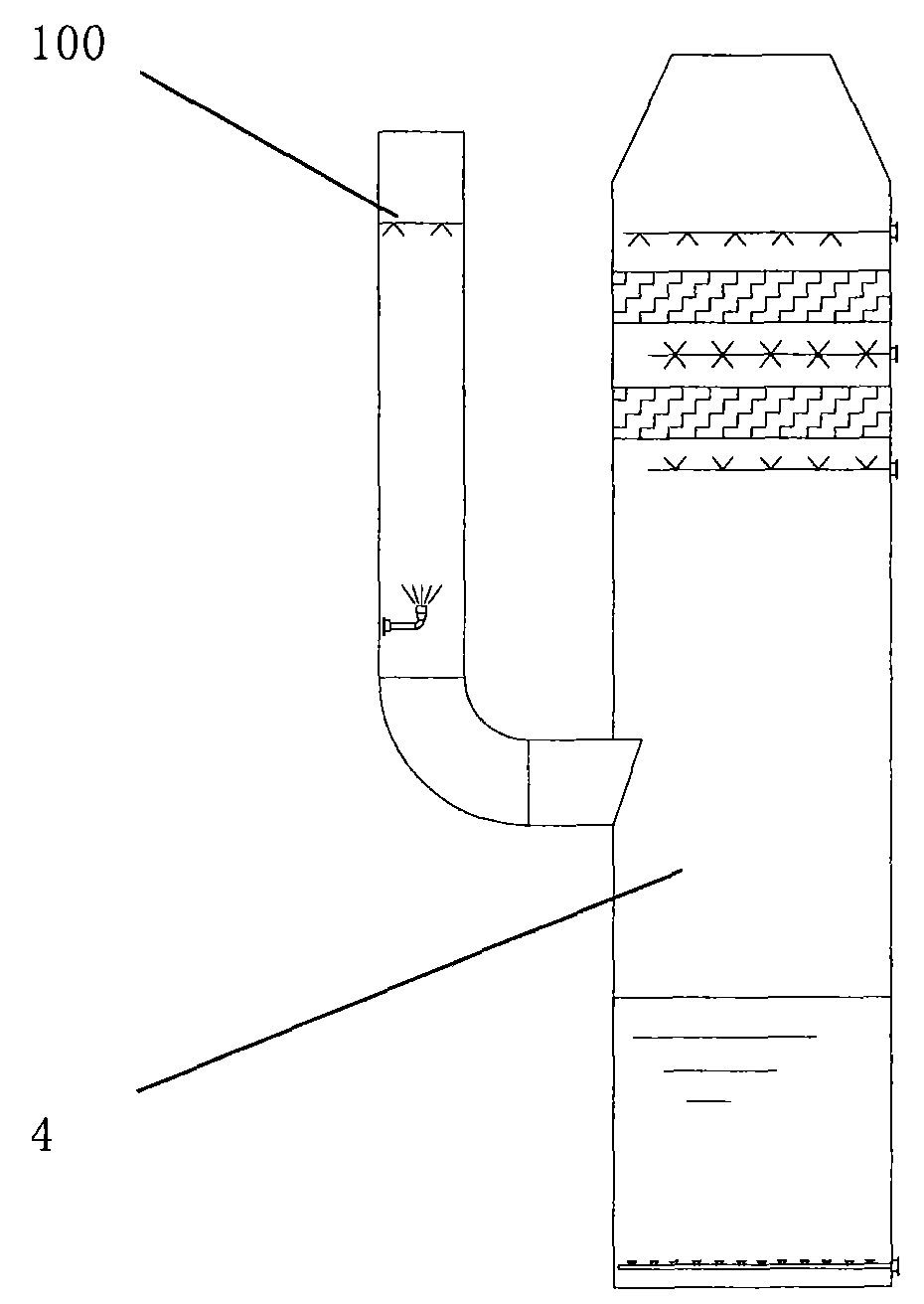

[0115] The device of the present invention includes a first unit and a second unit: the first unit is a desulfurization unit containing a desulfurization tower, which is used to absorb the original flue gas for desulfurization; the second unit is a unit made of ammonium sulfate composed of a vacuum crystallizer; The upstream of the vacuum crystallizer is connected to the outlet of the circulating slurry of the desulfurization tower; in the first unit, a chilling and dedusting tower is arranged upstream of the desulfurization tower for chilling and dedusting the original flue gas before entering The desulfurization tower performs desulfurization.

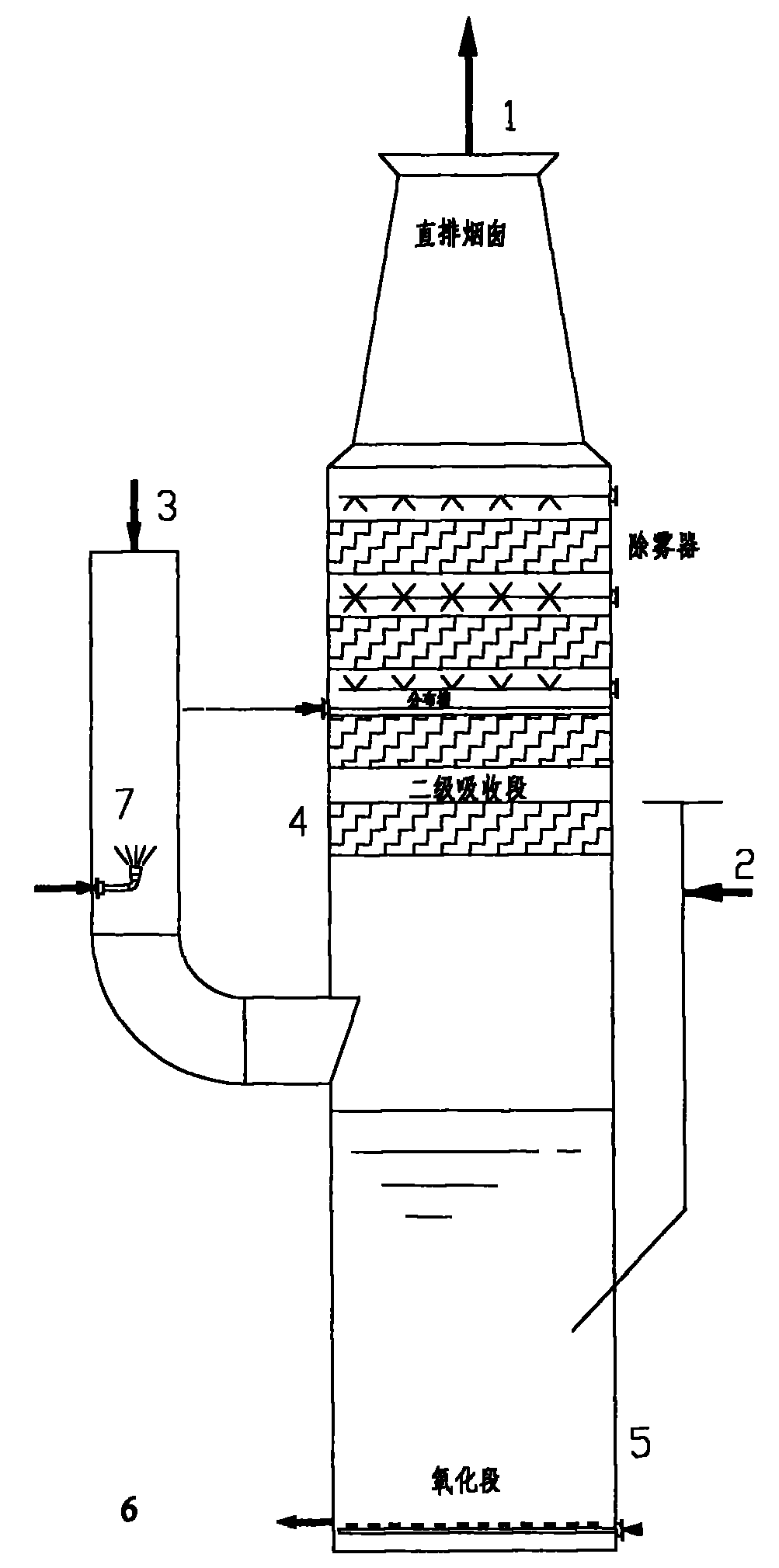

[0116] Such as figure 1 As shown, the structure of the desulfurization tower in the desulfurization unit of the first unit is shown: the top of the desulfurization tower is provided with a flue gas outlet 1 to discharge the net flue gas; the middle part of the desulfurization tower is also provided with ammonia Desulfurizer inlet 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com