Photovoltaic synchronization inverter with photovoltaic array IV test function and test method

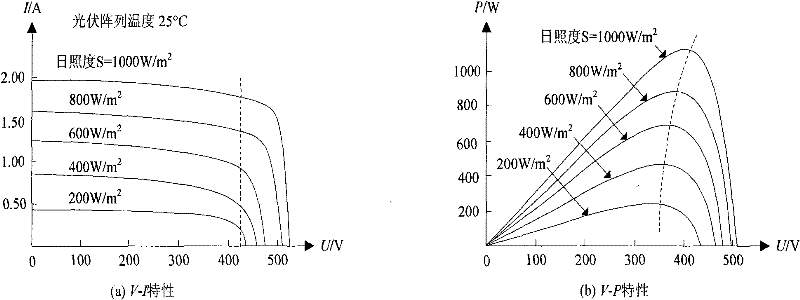

A photovoltaic array and testing function technology, which is applied in photovoltaic modules, photovoltaic power generation, and measurement of electrical variables, etc., can solve problems such as difficult to meet various power stations and inconvenient operation, achieve convenient service life and fault analysis, and improve power generation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

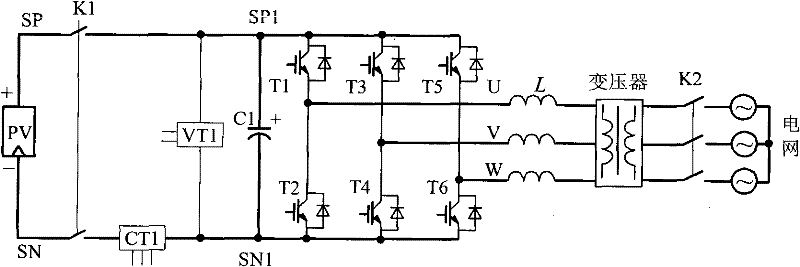

[0023] in figure 1 In the system of the present invention shown, ports SP and SN are the output ports of the photovoltaic array PV, K1 is a DC circuit breaker, which can be located outside or inside the system, manual or automatic, and U, V, and W are three inverter units. Phase output port, CT1 is the DC bus current sensor of the inverter unit, C1 is the DC filter capacitor, CT1 is located between the photovoltaic array PV and the filter capacitor C1, which can detect the output current of PV, VT1 is the DC voltage sensor, CT1 and VT1 are selected Precision high-speed Hall sensor, T1~T6 are the power module IGBTs in the inverter unit, and other components in the main circuit, including inductors and transformers, are set as usual.

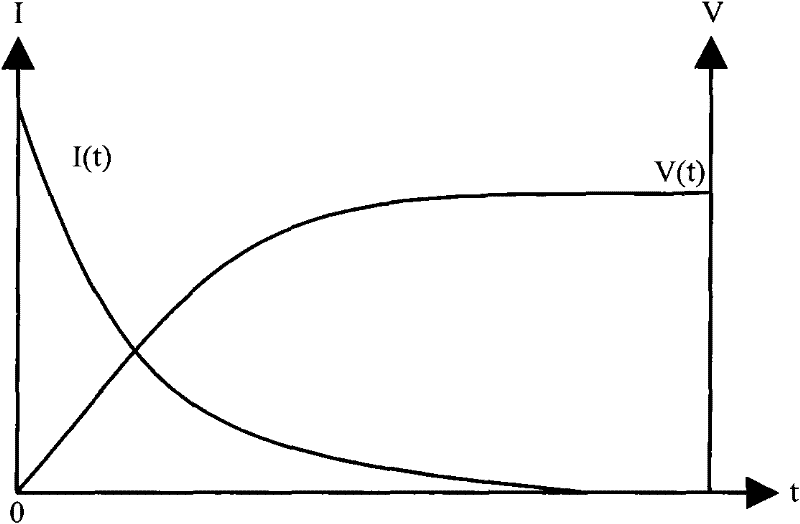

[0024] When testing the photovoltaic array PV, first stop, disconnect K1 and disconnect the inverter from the grid, and then wait for the voltage of the main circuit filter capacitor C1 to gradually self-discharge and drop to a suitable low voltage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com