Prestressing large-scale spiral fin steel tube

A prestressed steel wire and prestressed technology, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of short service life of steel pipes, increase the amount of steel used for pipes, and increase replacement costs. Overall cost, reduced corrosion, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

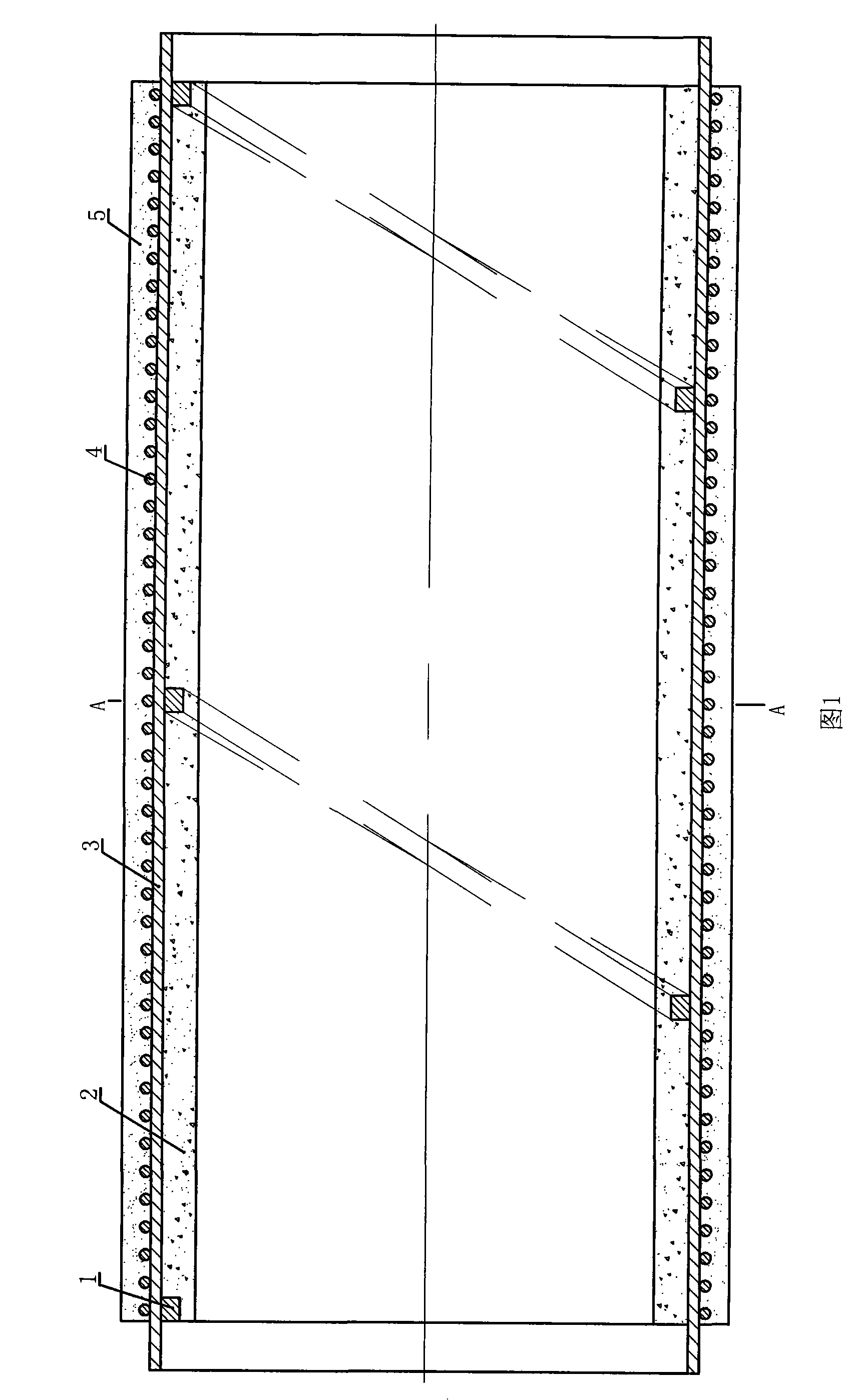

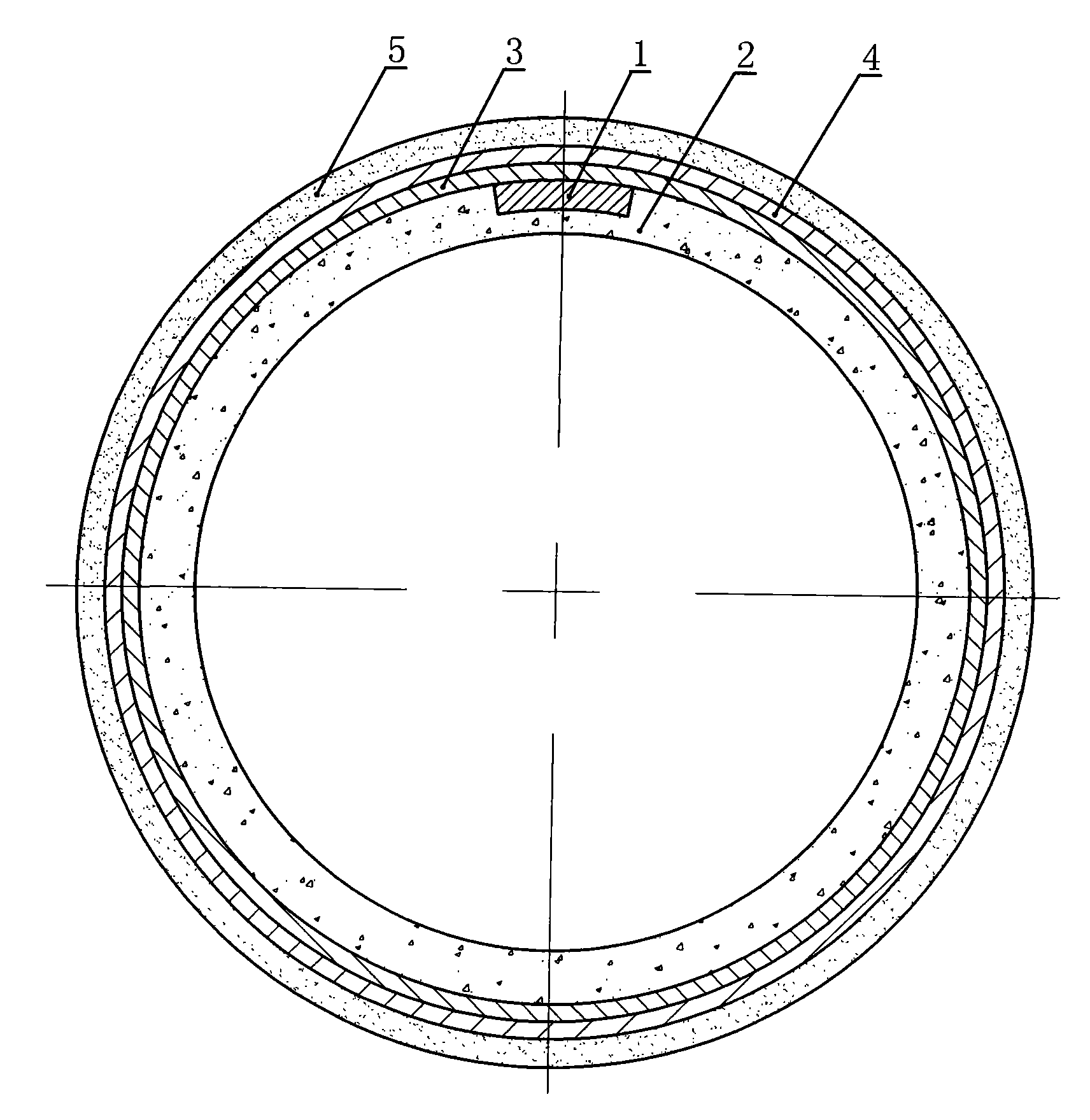

[0018] A prestressed large-scale spiral-ribbed steel pipe, which is composed of a steel pipe body 3, a protective layer, and a prestressed steel wire 4. The inner wall of the steel pipe pipe is coaxially fixed with an inner protective layer 2. The inner protective layer can be composite fiber cement mortar or composite Fiber concrete or other anti-corrosion materials, the inner protective layer of this embodiment is the former composite fiber cement mortar, and the outer wall of the steel pipe pipe is coaxially fixed with the outer protective layer 5, and the outer protective layer can be composite fiber cement mortar or composite fiber concrete or other anti-corrosion materials. Material, the outer protective layer of this embodiment is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com