Well blowout preventer mounted in drilling column and automatically controlled in well

A blowout preventer and drill string technology, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc. Comprehensive technical and economic benefits, saving operating costs, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

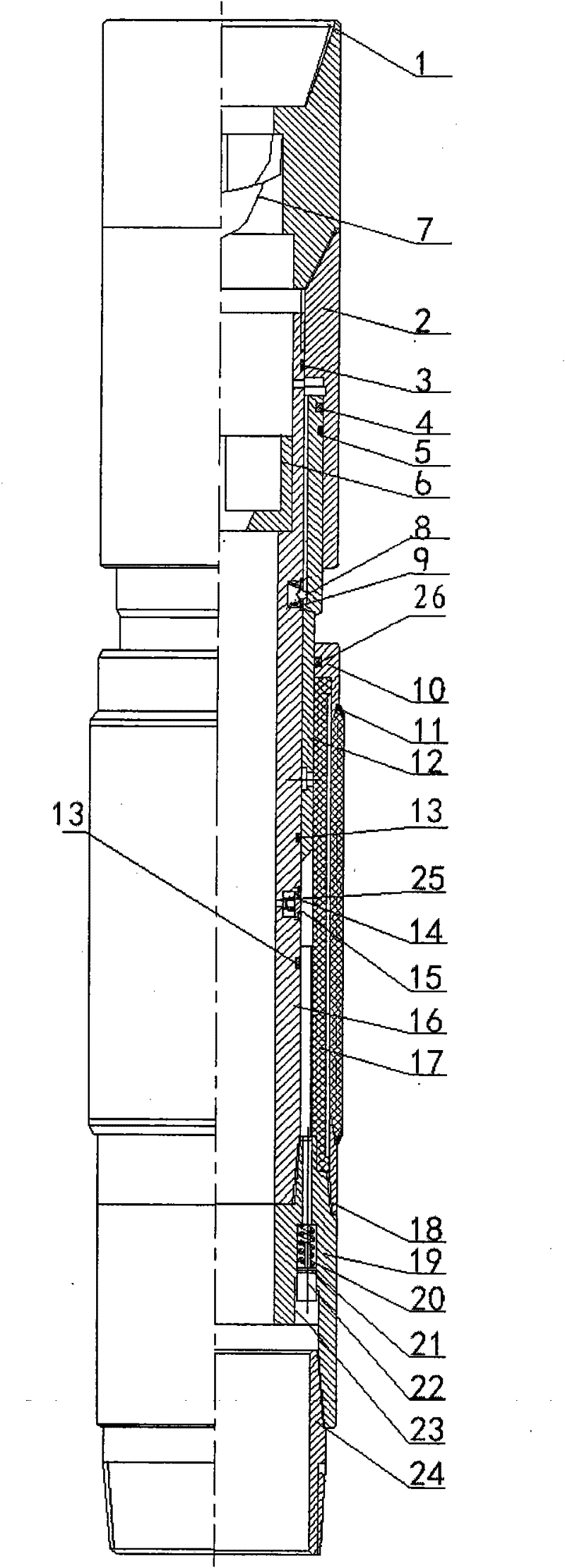

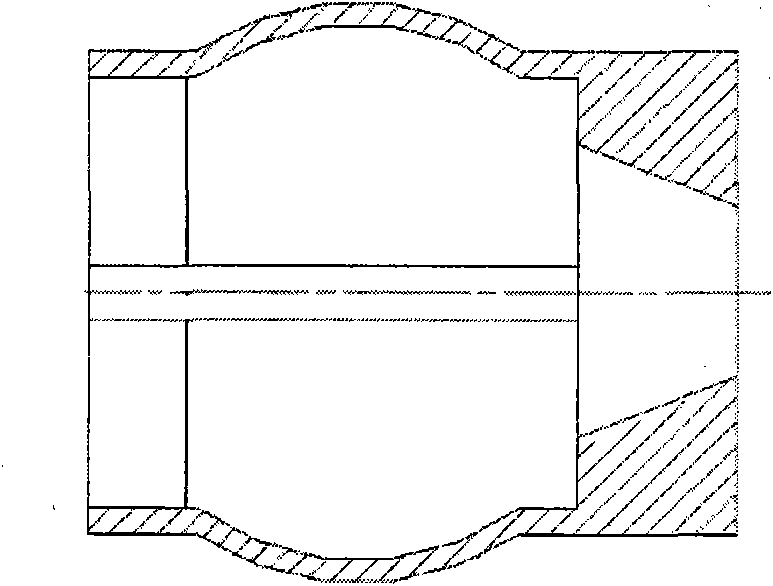

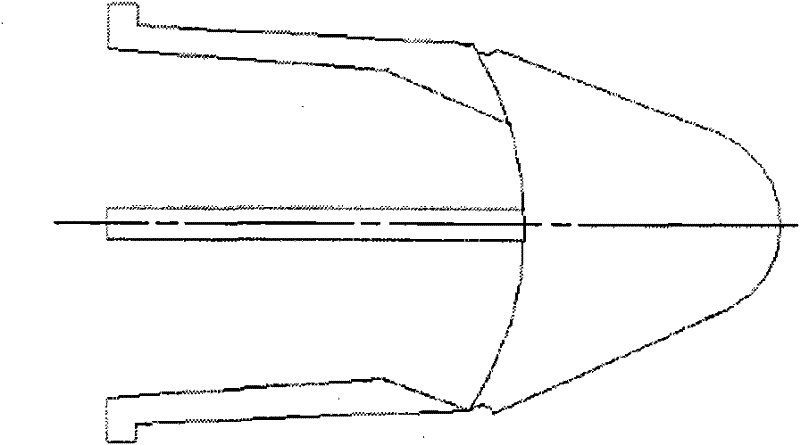

[0014] The downhole blowout preventer is composed of the drilling tool slide valve assembly and the main body of the downhole blowout preventer, such as figure 1 shown. Among them, the drilling tool spool valve assembly is composed of spool valve joint 1, spool valve seat 6, and spool valve body 7. Two-stage shaft shoulders are processed on the spool valve joint 1, and one is used for positioning and restricting the spool valve body 7. 7 downstrokes. One is used to install the spool valve seat 6 during the initial connection. The upper circular ring of the spool valve seat 6 is processed with a tapered hole, and a certain number of elastic elements are installed around it to facilitate close contact with the inner wall of the drill string, such as figure 2 shown. The upper part of the spool valve body 7 is a conical cylinder composed of multiple arcs and straight li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com