Protector for oil pipe working under pressure used for oil well

A technology of snubbing operation and protector, which is applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc. It can solve the problems of killing fluid loss and reservoir pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

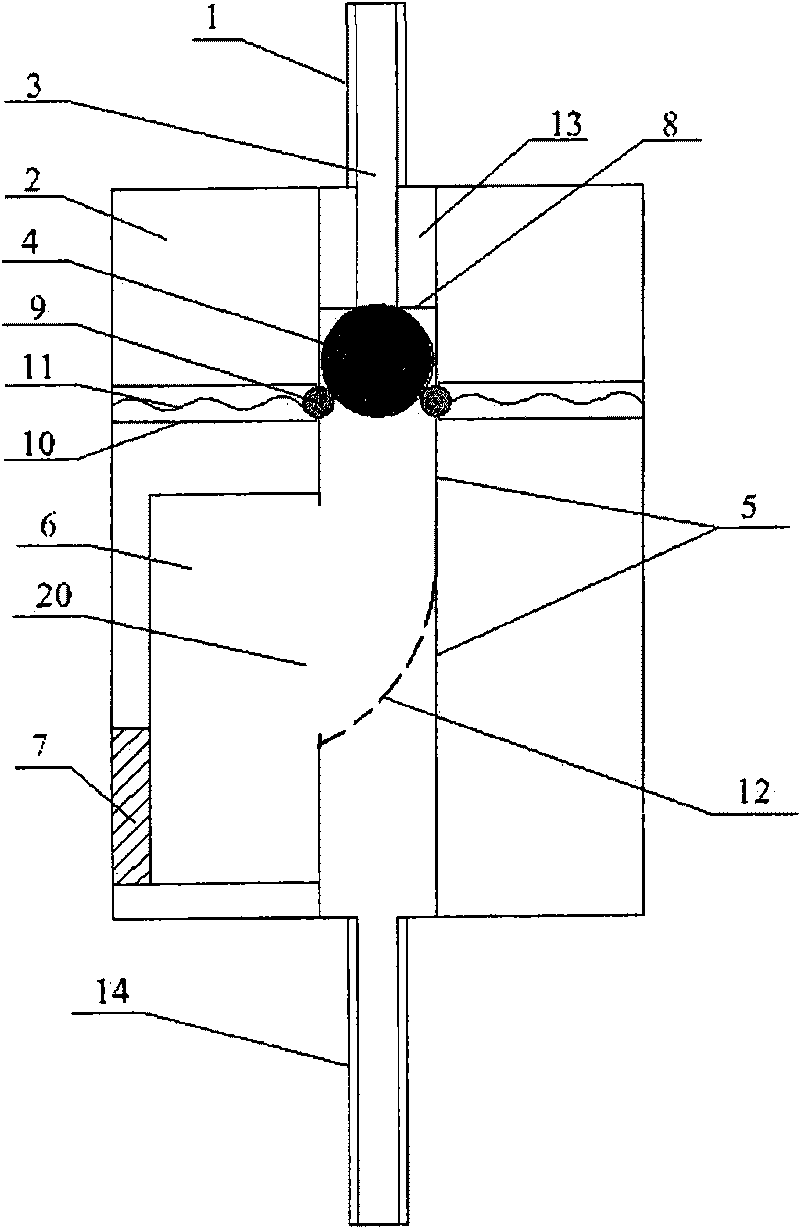

[0057] figure 1 Shown is the structure of the oil well tubing hot work protector in the initial state (that is, when it is not put into use) in this embodiment, wherein:

[0058] The upper joint 1 enters the inside of the sealing ball tube 5 through the opening of the sealing ball tube 5 on the upper end surface of the body 2, and this part of the sealing ball tube 5 forms a sealing ball installation channel 13; thread engagement, or on the side of the lower end of the upper joint 1, there is a thread engaged with the thread on the inner wall of the sealing ball tube 5; the outer wall of the upper joint 1 located outside the body is provided with a screw thread, which can be connected with the oil pipe of the upper wellhead Hanging and other components are connected;

[0059] The lower joint 14 communicates with the lower end of the sealing ball tube 5 and is located outside the body 2. The outer wall of the lower joint 14 is provided with a screw thread, which can be connect...

Embodiment 2

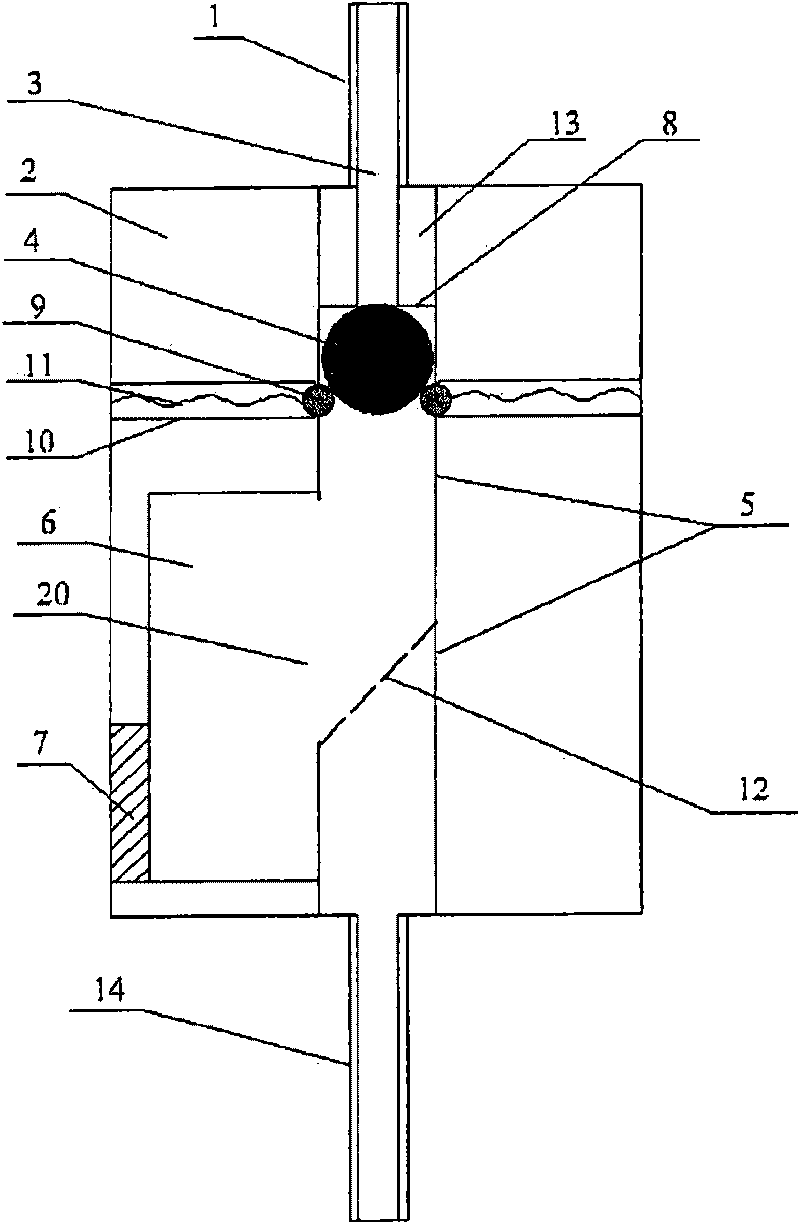

[0068] The structure of the oil well tubing hot work protector provided in this embodiment is as follows: figure 2 As shown, what is shown in this figure is also the structure of the protector when it is in the initial state (that is, when it is not put into use), wherein, compared with the oil well tubing hot work protector provided in Example 1, there are the following differences:

[0069] In the oil well tubing hot work protector provided in this embodiment, the guiding device (that is, the track 12 inside the sealing ball tube 5) is an inclined straight line, and its inclination angle is about 45° (the angle with the horizontal plane).

[0070] Other structures of the oil well tubing snubbing protector provided in this embodiment are the same as those of the oil well tubing snubbing protector provided in Embodiment 1.

Embodiment 3

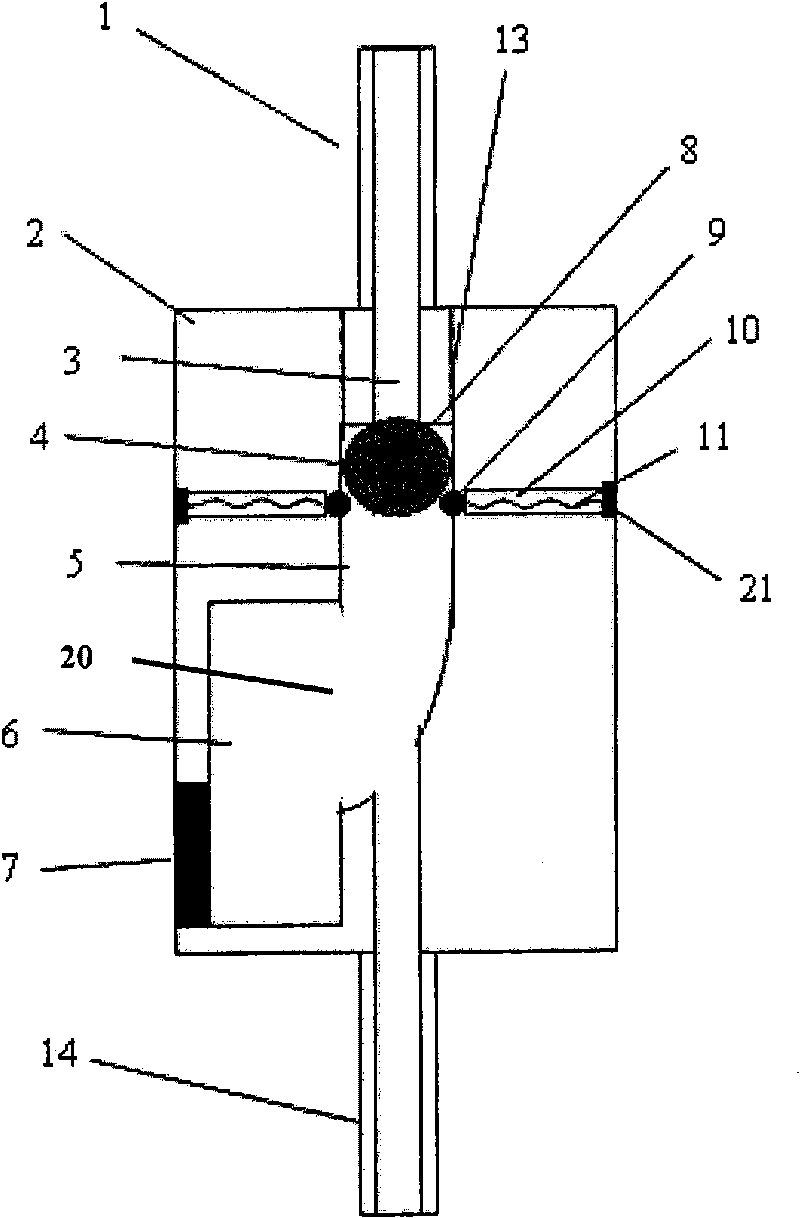

[0072] The structure of the oil well tubing hot work protector provided in this embodiment is as follows: image 3 As shown, what is shown in this figure is also the structure of the protector when it is in the initial state (that is, when it is not put into use), wherein, compared with the oil well tubing hot work protector provided in Example 1, there are the following differences:

[0073] In the protector for oil well tubing under pressure provided in this embodiment, no track 12 is provided inside the sealing ball tube 5, but the corresponding position of the track 12 in embodiment 1 forms an arc (that is, a necking structure), and becomes a sealing ball tube The lower end of 5, that is, the guiding device is the arc-shaped lower end of the sealing ball tube 5;

[0074] The lower joint 14 enters the interior of the body 2 and communicates with the arc-shaped lower end of the sealing bulb 5;

[0075] The limiting device is fixed on the inner wall of the body 2 by fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com