Method and process for recovering chromium from chromium residue by chlorination segregation method

A technology of chromium slag and disposal method, applied in the direction of chromium halide, climate sustainability, sustainable waste treatment, etc., can solve problems such as secondary pollution, achieve the advantages of less equipment investment, good promotion and application prospects, and solving secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

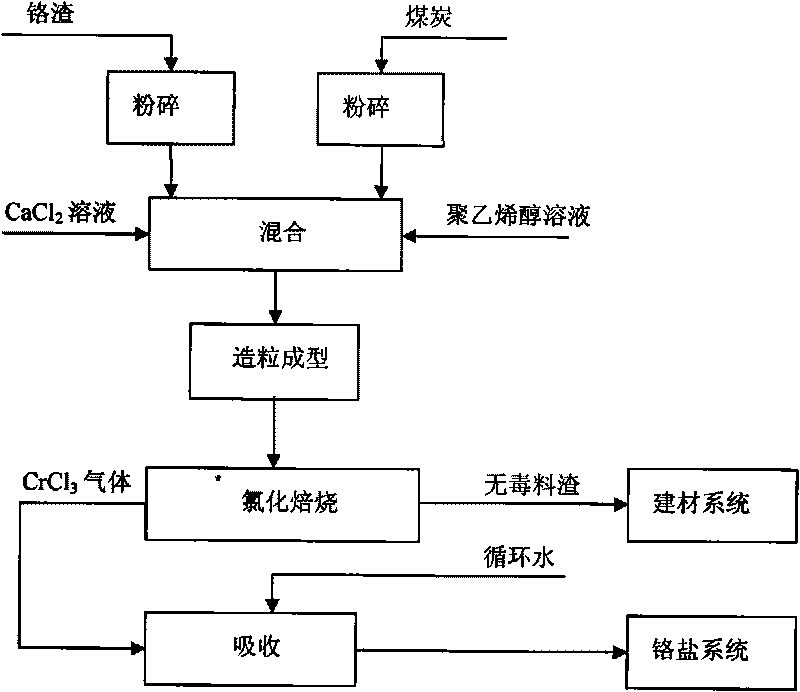

Method used

Image

Examples

Embodiment 1

[0025] Grind 500g of chromium slag and 20g of coal to 80 mesh respectively, mix thoroughly, add 20mL of calcium chloride and 10mL of 3% polyvinyl alcohol aqueous solution, mix evenly, and then granulate to form particles with a diameter of 4mm and a length of 10mm. Transfer to the tubular roaster, after roasting at 980°C for 50 minutes, the gas out of the roaster was absorbed with water to obtain 500 mL of chromium trichloride aqueous solution; 493.1 g of slag was obtained. The total chromium content of the slag was less than 5 ppm (hexavalent chromium content below 1ppm).

Embodiment 2

[0027] Grind 500g of chromium slag and 20g of coal to 80 mesh respectively, mix thoroughly, add 20mL of calcium chloride and 10mL of 3% polyvinyl alcohol aqueous solution, mix evenly, and then granulate to form particles with a diameter of 4mm and a length of 10mm. Transfer to the tubular roaster, after roasting at 980°C for 80 minutes, absorb the gas out of the roaster with water to obtain 500 mL of chromium trichloride aqueous solution; obtain 492.5 g of slag. The total chromium content of the slag is 4.2 ppm (hexavalent chromium content below 1ppm).

Embodiment 3

[0029] Grind 500g of chromium slag and 20g of coal to 80 mesh respectively, mix thoroughly, add 20mL of calcium chloride and 10mL of 3% polyvinyl alcohol aqueous solution, mix evenly, and then granulate to form particles with a diameter of 4mm and a length of 10mm. Transfer to the tubular roaster, after roasting at 980°C for 90 minutes, absorb the gas out of the roaster with water to obtain 500 mL of chromium trichloride aqueous solution; obtain 492.4 g of slag. The total chromium content of the slag is 4.1 ppm (hexavalent Chromium content is less than 1ppm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com