Composite board with sandwich components for transport facility

A technology for transportation tools and composite boards, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., and can solve the problems of not considering the sandwich components, not considering the different performance requirements of the sandwich components, etc. , to achieve the advantages of high performance and cost performance, outstanding comprehensive performance, and the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

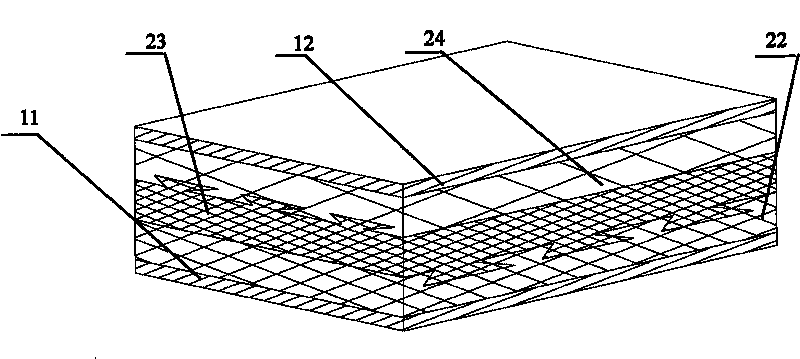

[0027] Such as figure 1 As shown, it is a three-layer sandwich two-component composite panel, the total thickness is generally 20mm to 80mm. The total thickness of the composite board in this embodiment is 60mm. The skin is a thin plate such as aluminum plate, steel plate, glass steel plate or carbon fiber plate, and the thickness is generally 0.2mm to 10.0mm. In this embodiment, the first skin 11 is a 1.2mm aluminum plate, and the second skin 12 is a 1.0mm aluminum plate; the sandwich part includes three layers of sandwich materials, and the sandwich material is a PEI core material 25 with a thickness of 10 mm to 15 mm and a thickness of 24 combinations of PMI core materials of 27.8-37.8mm. Wherein, the PEI core material 25 is connected with the skin, and the PMI core material 24 is sandwiched inside two layers of PEI core materials 25 . The first skin 11 , the PEI core 25 , the PMI core 24 , the PEI core 25 and the second skin 12 are sequentially bonded by an adhesive to ...

Embodiment 2

[0031] Such as figure 2 As shown, it is a two-layer sandwich composite board with two components, the total thickness is generally 20mm to 80mm, and the total thickness of the composite board in this embodiment is 60mm. The skin is a thin plate such as aluminum plate, steel plate, glass steel plate or carbon fiber plate, and the thickness is generally 0.2mm to 10.0mm. In this embodiment, the first skin 11 is a 1.0mm aluminum plate, and the second skin 12 is a 1.0mm stainless steel; the sandwich part includes two layers of sandwich materials, and the sandwich material is a PES core material 22 with a thickness of 10 mm to 15 mm and a thickness of 43mm ~ 48mm PMI core material 24 combinations. The first skin 11 , the PES core 22 , the PMI core 24 and the second skin 12 are sequentially bonded by an adhesive to form a composite board.

[0032] The first skin 11 is made of lightweight aluminum plate, which can effectively reduce the weight of the composite plate and ensure suff...

Embodiment 3

[0035] Such as image 3As shown, it is a three-layer sandwich three-component composite board, and the total thickness is generally 20mm to 80mm. The total thickness of the composite board in this embodiment is 60mm. The skin is a thin plate such as aluminum plate, steel plate, glass steel plate or carbon fiber plate, with a thickness of 0.2mm to 10.0mm. In this embodiment, the first skin 11 is 2.0mm stainless steel, and the second skin 12 is 2.0mm stainless steel; the sandwich part includes three layers of sandwich materials, and there are three kinds of sandwich materials, and the sandwich materials are selected from PES core material 22, PVC The combination of the core material 23 and the PMI core material 24 is connected by buckling. The first skin 11 is bonded to the PES core material 22 with a thickness of 15 mm to 20 mm through an adhesive, and the second skin 12 is connected to the PMI core material 24 through an adhesive bond, wherein the thickness of the PMI core m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com