Prebaked-anode template for aluminium electrolysis and preparation and forming technology thereof

A technology of pre-baked anode and molding process, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problem of increasing power consumption, pre-baked anode loss consumption, increasing molten electrolyte viscosity, uncleanliness, and destroying aluminum electrolysis process technical conditions and other problems to achieve the effect of reducing carbon consumption, reducing consumption and improving anode quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

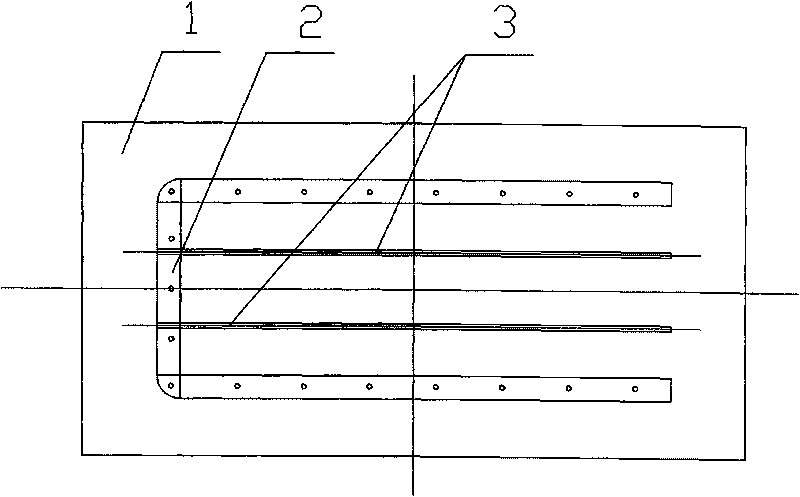

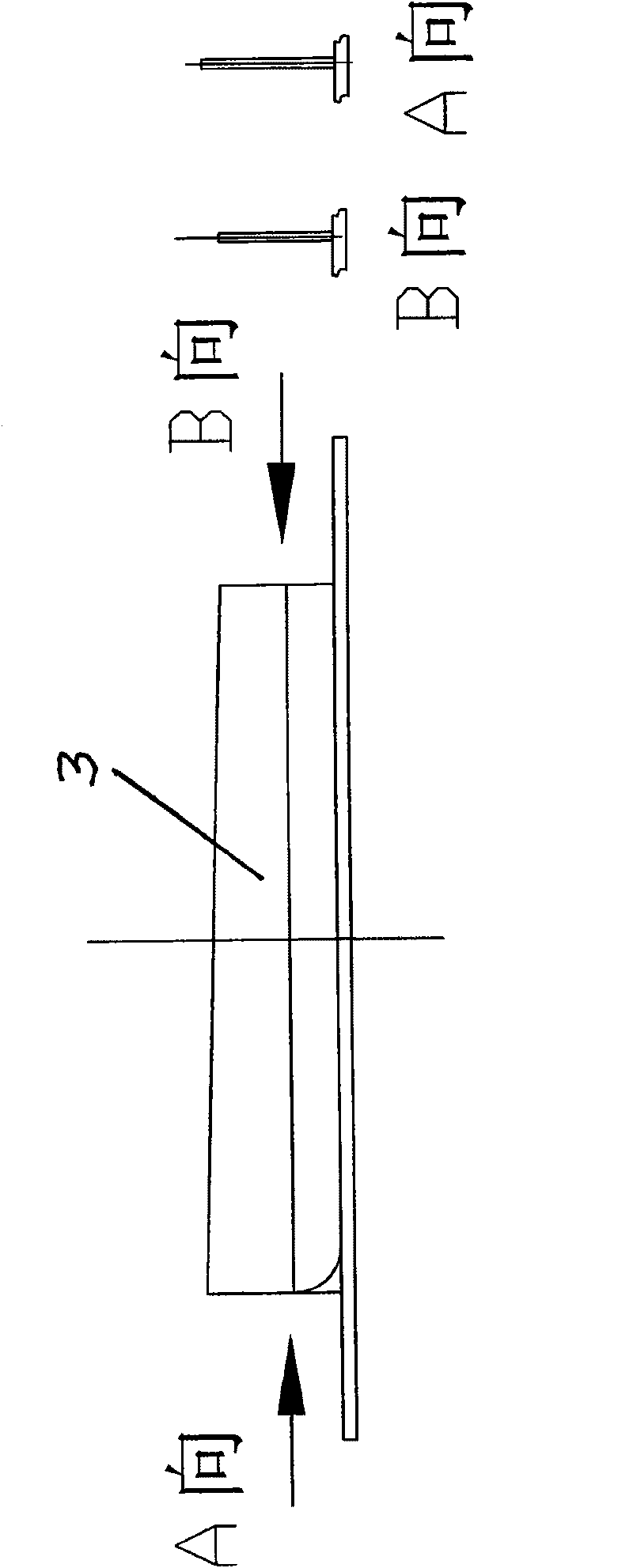

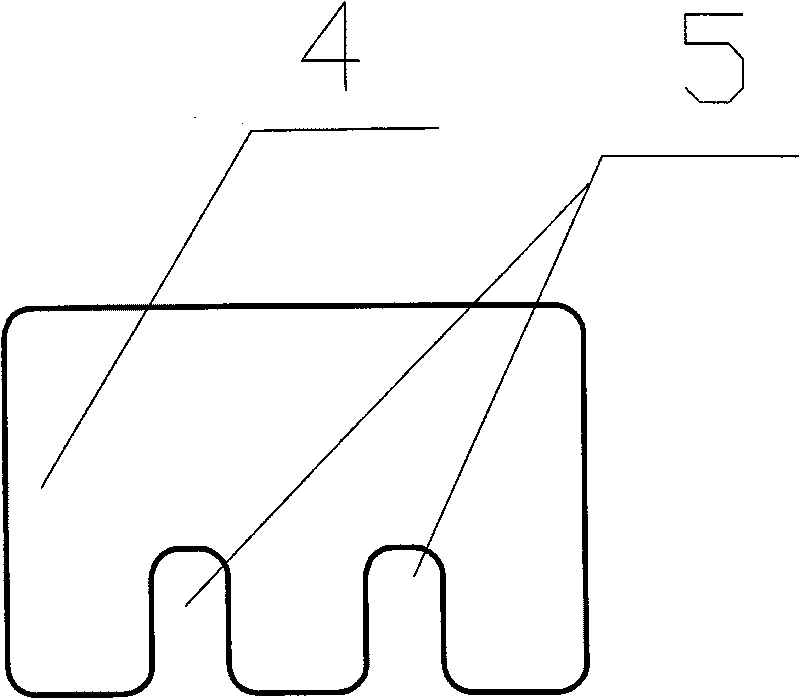

[0017] As shown in the figure; taking the formwork bottom plate with chamfering and vertical slotted plate as an example, the technical solution is completed by the following manufacturing process:

[0018] 1. According to the size of the vibrating table of the prebaked anode vibration forming machine, select the prebaked anode template bottom plate (1) with slots and chamfers of the same size as the original vibrating table;

[0019] 2. According to the product design requirements, process the pre-baked anode formwork bottom plate (1) and the circular chamfering formwork (2). After the production is completed, dig holes in the slotted chamfering formwork (1), and weld and inlay from the reverse side of the formwork bottom plate. And polished smooth; changed from the right-angled chamfering plane with a 90° angle on the palm surface of the anode bottom to the circular-arc chamfering with a certain radius.

[0020] 3. Make a prebaked anode bottom slotted template (3) separately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com