Frozen dumpling modifying agent, preparation method thereof and application

A technology for quick-frozen dumplings and an improver, which is applied in the directions of application, pre-baked dough processing, baking, etc., can solve the problems of reduced freeze-thaw stability, hard dough, and difficult to cook through, and achieves good freeze-thaw stability and improved freeze-thaw stability. Boil resistance, appearance and taste enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Quick-frozen dumpling improver, raw material parts by weight ratio: 35 parts of active soybean flour, 38 parts of konjac flour, 5 parts of compound enzyme, 12 parts of carrageenan, 10 parts of starch phosphate; the compound enzyme is xylanase The mixture with the mass ratio of glucose oxidase is 2:1.

[0025] The preparation process is as follows: take each raw material in parts by weight, pass each raw material through a CB36 sieve, then mix the compound enzyme with starch phosphate, and then mix the mixture with the rest of the raw materials in a cone mixer for 7 minutes to obtain the obtained Describe quick-frozen dumpling improver.

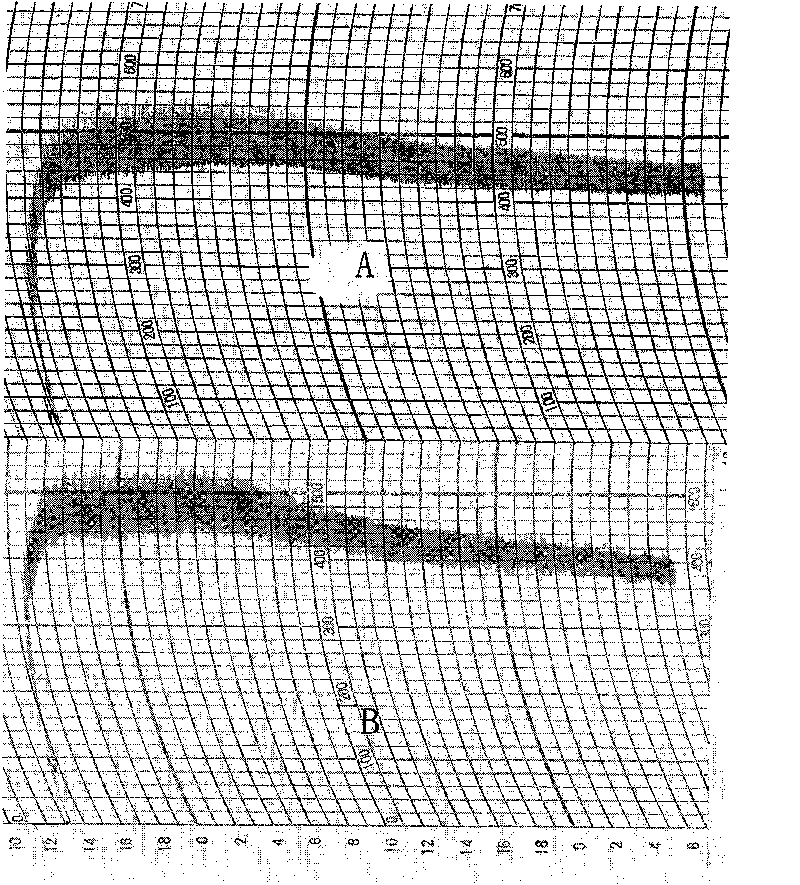

[0026] According to the dosage of 0.4%, it is directly added to the flour when kneading the dough or is dissolved in food production water and added to the flour when kneading the dough. The stability time of the dough is measured by the German Brabender farinograph, so as to investigate the addition of this product. The degree of resi...

Embodiment 2

[0029] The quick-frozen dumpling improving agent has the ratio of raw materials by weight: 40 parts of active soybean powder, 30 parts of konjac flour, 5 parts of compound enzyme, 10 parts of carrageenan, and 15 parts of starch phosphate. The compound enzyme is a mixture of xylanase and glucose oxidase with a mass ratio of 1.8:1

[0030] The preparation process is as follows: take each raw material in parts by weight, pass each raw material through a CB36 sieve, then first mix the compound enzyme with 10 parts of starch phosphate, and then mix the mixture with the rest of the raw materials in a cone mixer for 8 minutes, namely Obtain the quick-frozen dumpling improving agent.

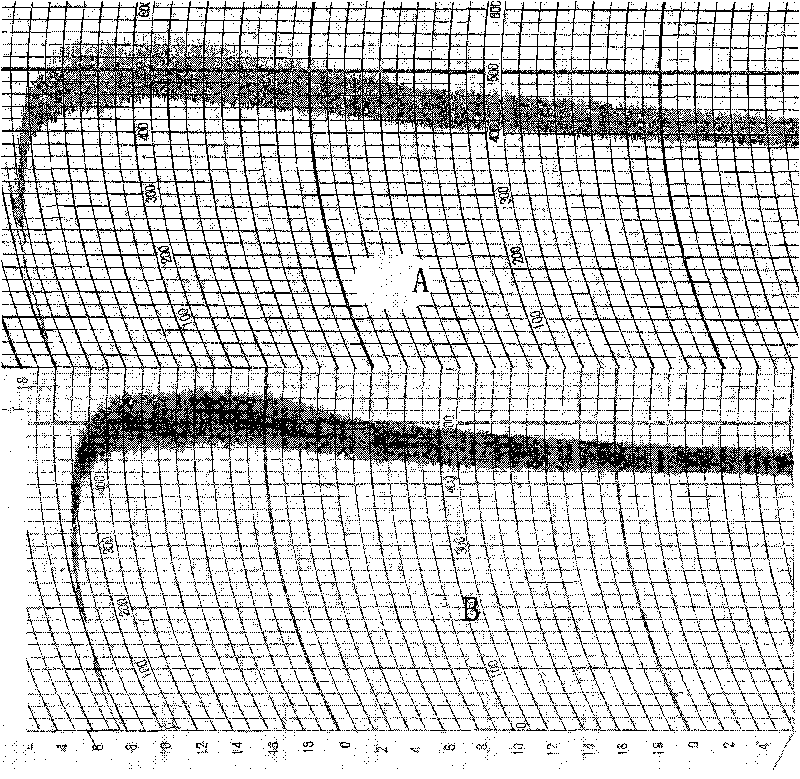

[0031] According to the dosage of 0.35%, it is directly added to the flour when kneading the dough or is dissolved in food production water and added to the flour when kneading the dough, and the stability time of the dough is measured by a German Brabender farinograph. figure 2 Among them, A is the f...

Embodiment 3

[0034] Quick-frozen dumpling improver, raw material parts by weight ratio: 42 parts of active soybean flour, 32 parts of konjac flour, 5 parts of compound enzyme, 8 parts of carrageenan, 17 parts of starch phosphate; the compound enzyme is xylanase The mixture with the mass ratio of glucose oxidase is 2.3:1.

[0035] The preparation process is the same as in Example 2.

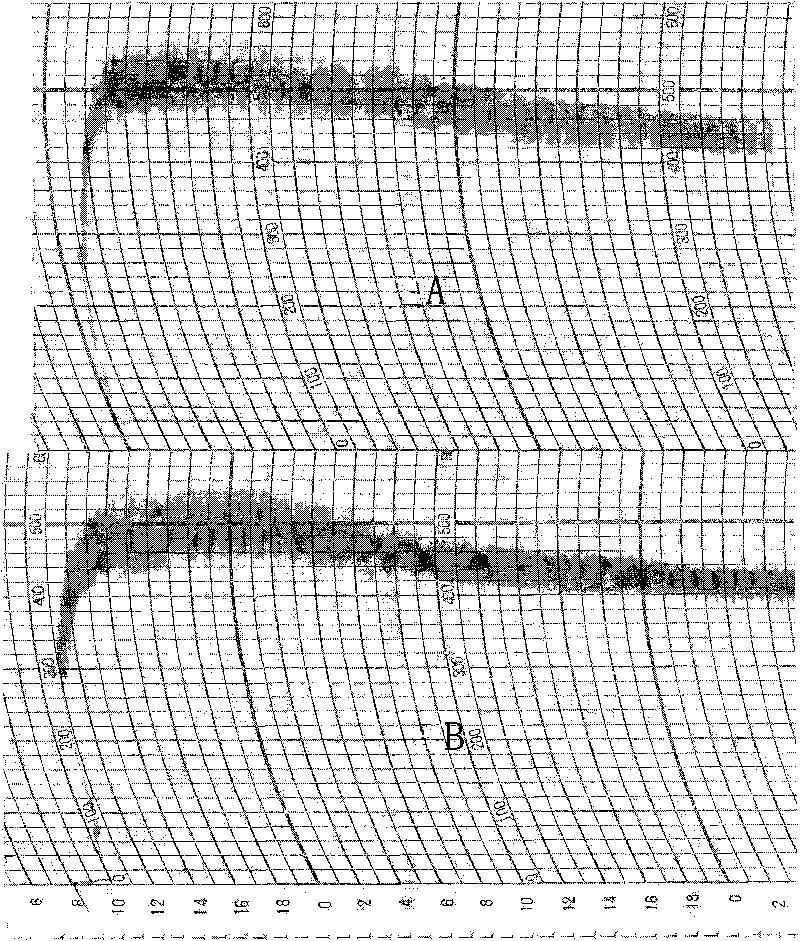

[0036] According to the dosage of 0.3%, it is directly added to the flour when kneading the dough or is dissolved in food production water and added to the flour when kneading the dough, and the stability time of the dough is measured by a German Brabender farinograph. image 3 Among them, A is the flour curve of the dough that adds the improving agent of this embodiment, and B is the flour curve of the control dough (without adding the improving agent of this embodiment). It can be seen that the stability time ratio of the dough that has added the improving agent of this embodiment The control dough was 1.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com