Method for designing structure of low-cost test combustion chamber with reliable thermal protection

A technology of structural design and combustion chamber, which is applied in the field of structural design of low-cost experimental combustion chambers with reliable thermal protection, can solve the problems of overheating ablation, high cost, and low cost, and achieve measurement accuracy, low cost, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate the present invention with embodiment below in conjunction with accompanying drawing, present embodiment is a test liquid rocket engine thrust chamber.

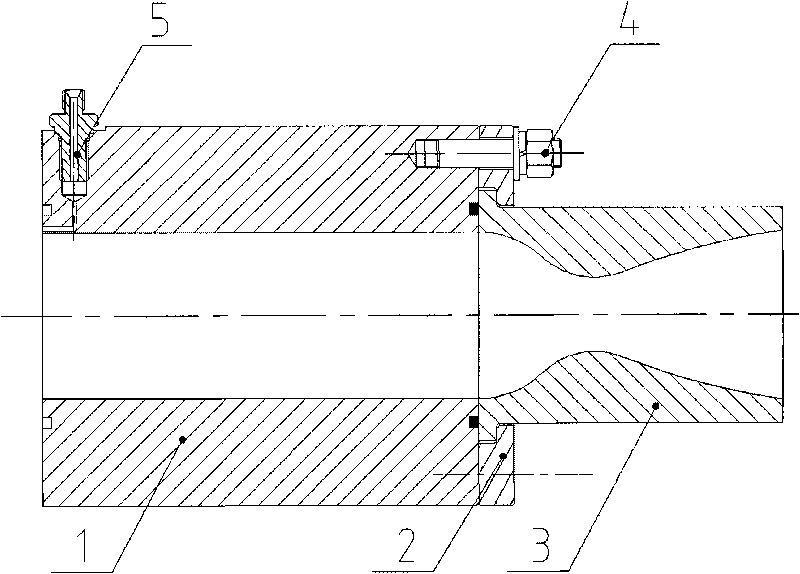

[0015] The combustion chamber designed by this method mainly includes: body cylinder section 1, connecting flange 2, tail nozzle 3, connecting bolt 4 and necessary pressure measuring nozzle 5.

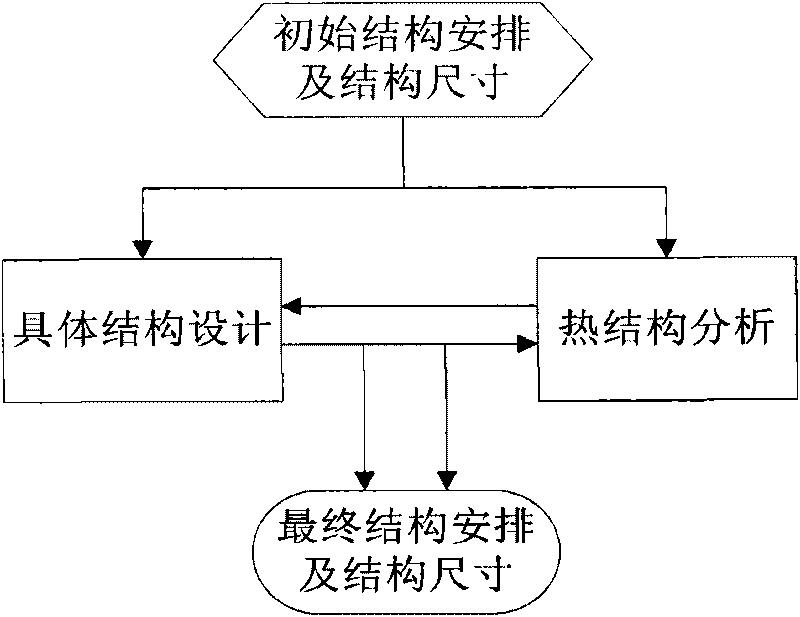

[0016] The whole design process is arranged as follows:

[0017] 1. First, the thermal analysis calculation model and calculation method must be established:

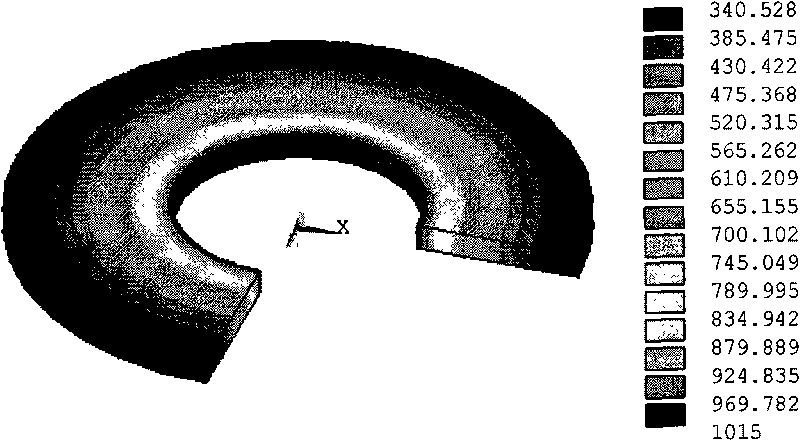

[0018] 1) Thrust chamber wall temperature calculation model

[0019] The copper and tungsten copper-infiltrated chamber wall is the calculation area, which conducts heat in an unsteady state. The body structure presents typical three-dimensional characteristics. The three-dimensional unsteady heat conduction differential equation is used:

[0020] pc ∂ t ∂ τ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com