Heat converter for heating automobile

A technology for heat exchangers and automobiles, applied in heat exchange equipment, heat exchanger types, heat exchanger shells, etc., can solve problems such as leakage, reduce heater efficiency, lack of sealing, etc., to achieve pressure-resistant liquid-tight, firm brazing The effect of easy connection and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

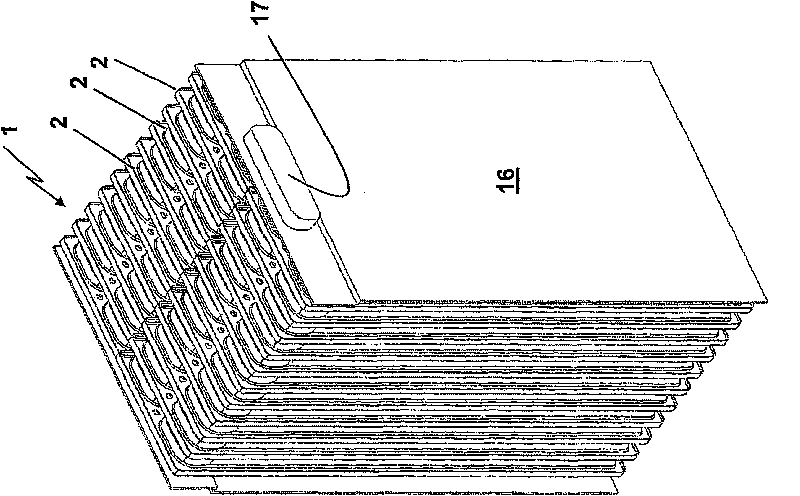

[0032] figure 1 Among them is a heater 1 according to the present invention with a plate structure, that is, the heater 1 is composed of a plurality of plates 2, which form a flow channel for the heat-carrying fluid, preferably coolant, in the cooling circuit of the automotive internal combustion engine. The plate 2 has dish-shaped openings 3 , 4 , 5 , 6 in its upper region, which together with adjacent dish-shaped openings (also referred to simply as dishes 3 , 4 , 5 , 6 ) form collecting ducts 7 , 8 , 9, 10. The term "collecting pipe" used here only also includes the concept of "distributing pipe". Furthermore, the plate 2 has non-perforated partitions 11 , 12 and a centrally penetrated partition 13 . All the plates 2 are made of aluminum and are brazed together, as will be explained further below. The flow route of the coolant is schematically indicated by arrows K1 to K9 indicating flow. The non-penetrating partitions 11, 12 form baffle areas 14, 15 through which the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com