Water heater for electromagnetic cooker

A water heater and stainless iron plate technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of electric heating pipes leaking and killing people, unsafe water heaters, and large sinks, saving electricity costs, Space saving, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

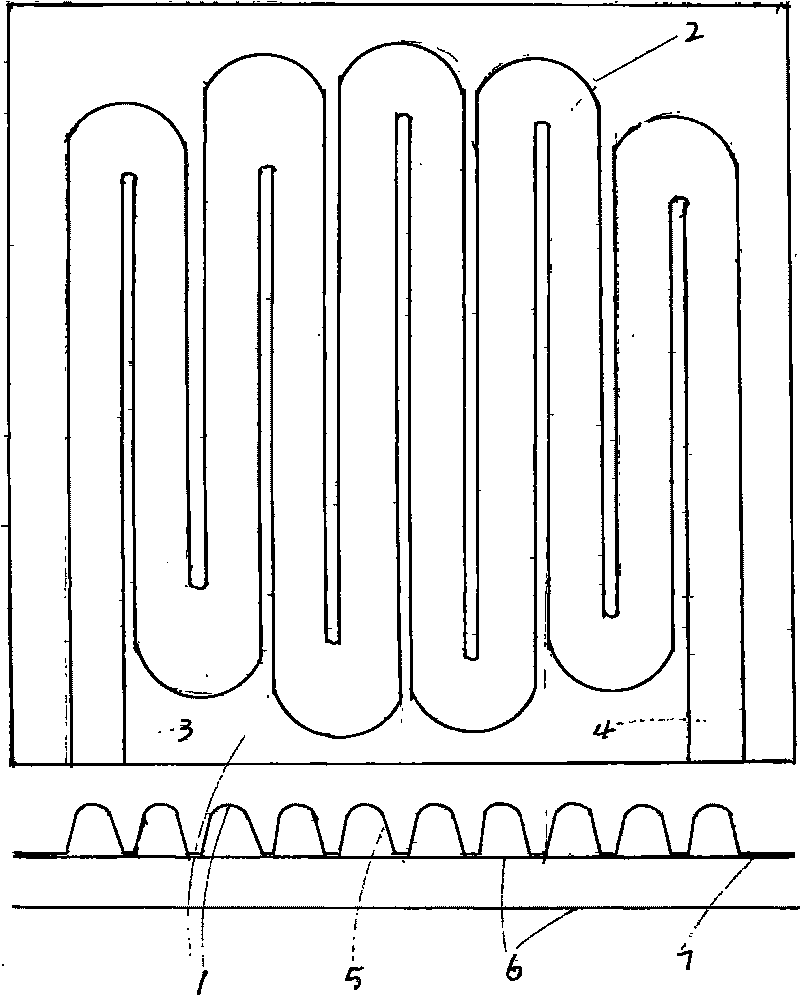

[0034] Please refer to figure 1 The schematic diagram of the structure of the dense pipe arrangement is that a piece of stainless iron plate is pressed into a grooved iron plate 1 by a punching die, and a stainless iron plate 6 is covered under the grooved iron plate 1, and is welded by spot welding and peripheral welding. Become a watertight dense pipe 7, water flows in from the low position 3, bends and flows along the inside of the pipe, absorbs heat and heats up, flows out from the high place 4, and completes the heat absorption process of the first group of pipes, the temperature is relatively low, still uncomfortable bathe.

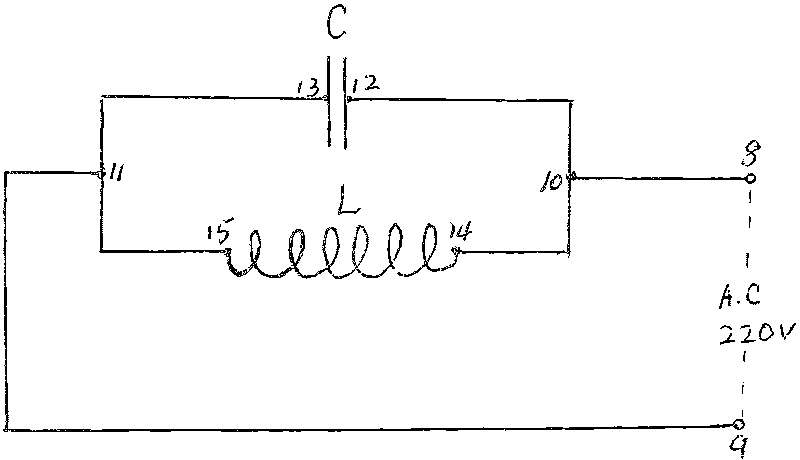

[0035] Please refer to figure 2 : Schematic diagram of the academic principle structure of the electromagnetic cooker heating element. This is a tuned circuit, which is called an oscillator circuit in radio science, and consists of a parallel circuit composed of a capacitor C and a coil L. When the 220V power supply is connected through 8 and 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com