On-line soot blowing method and on-line soot blowing device for coal water slurry boiler

A coal-water slurry and boiler technology, which is applied in the direction of combustion method, combustion product treatment, solid residue removal, etc., can solve the problems of difficult cleaning of boiler ash accumulation and high labor intensity of workers, so as to achieve low labor intensity of workers and clean ash Good effect and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

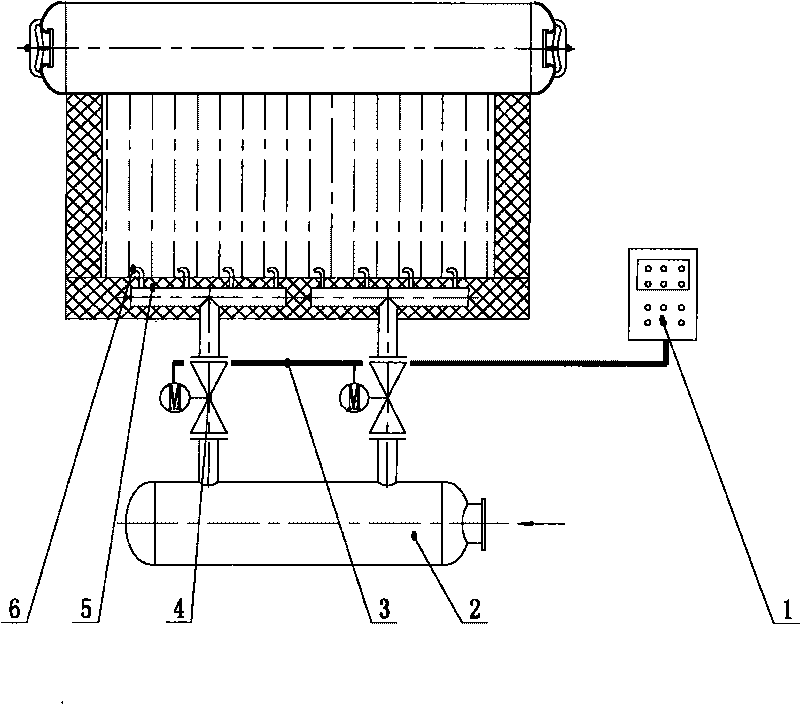

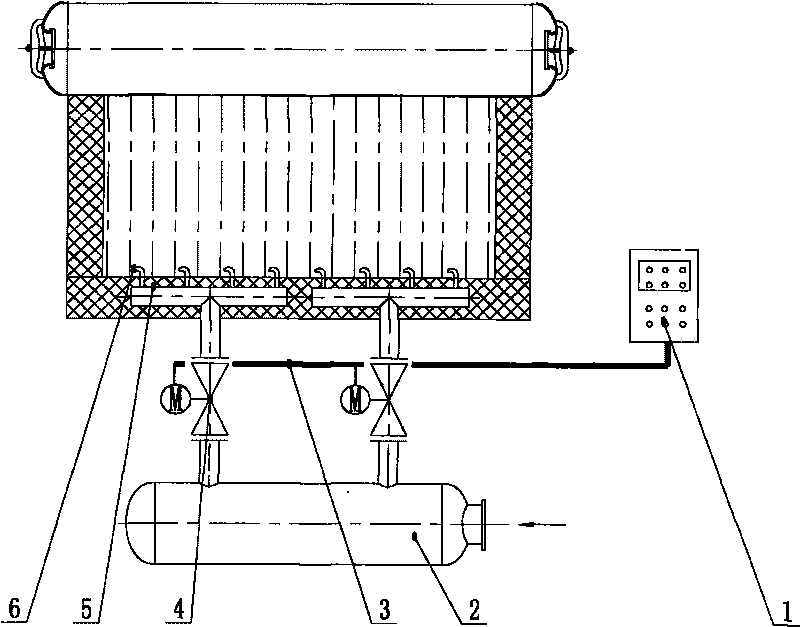

[0017] It can be seen from Fig. 1 that the present invention is an online soot blowing method for a coal-water slurry boiler. The method is to arrange a soot blowing device along the flue gas flow direction at the bottom of the convective heating surface of the coal-water slurry boiler. There are more than two nozzles with oblique upward outlets arranged in the gas flow direction. The soot blowing device can spray high-pressure steam or compressed air in sequence through the nozzles along the flue gas flow direction, and the interior of the heating surface of the boiler is divided in sequence by high-pressure steam or compressed air. The section is purged, and the large and coarse particles deposited in the flue gas channel of the boiler heating surface are forced to rise again due to the impact of the strong air flow, and at the same time collide with the metal wall of the heating surface, so that the dust adhering to the metal wall is caused by external force. The effect will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com