Method to generate electricity or supply heat by latent heat of turbine discharge

A steam turbine and latent heat technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of large investment, uneconomical, and unenvironmental protection of cooling towers, saving investment and space, saving heat and electricity, and reducing coal consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

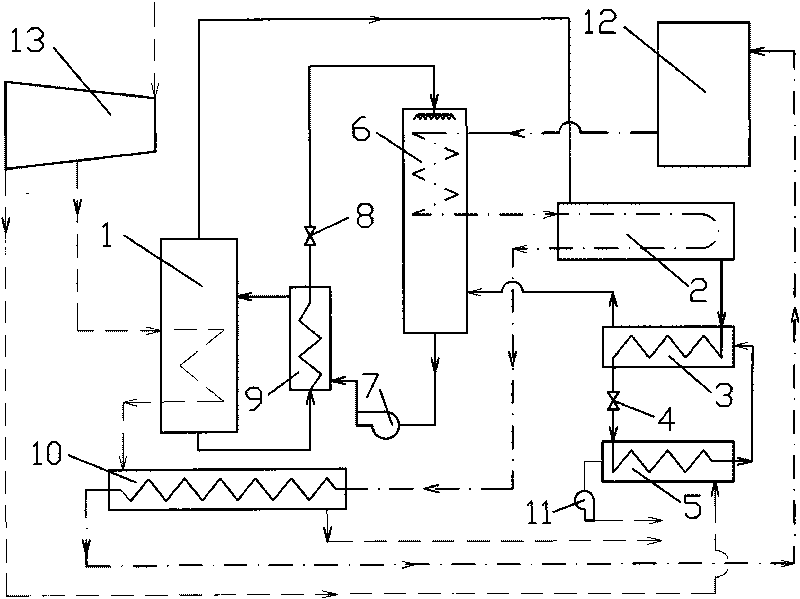

[0014] exist figure 1 In the process, the exhaust steam of the steam turbine is introduced into the evaporator (5) in the absorption heat pump cycle, and the heat pump working fluid is used to absorb the latent heat released by the exhaust steam of the steam turbine, which is upgraded to a high-grade heat source through the absorption heat pump cycle, and the heat energy is transferred to kalina Working fluid in the power cycle. The working fluid in the Kalina power cycle is heated in the heat pump cycle absorption tower (6), heated in the second stage in the condenser (2), and heated in the third stage in the heat exchanger (10) to become superheated steam , into the steam turbine in the kalina cycle to generate power. The circulating working medium of the absorption heat pump is a non-azeotropic mixed working medium pair, and the heat energy required for the separation of the non-azeotropic mixed working medium pair is provided by the low-grade steam extracted by the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com