Last-stage moving blade of air-cooled feed pump steam turbine

A technology of feed pump steam turbine and moving blade, which is applied in the direction of machine/engine, blade supporting element, mechanical equipment, etc., can solve the problems of lack of unified design specifications, poor unit economy, and high blade dynamic stress, and achieve broad market application prospects, Good damping characteristics and small dynamic stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

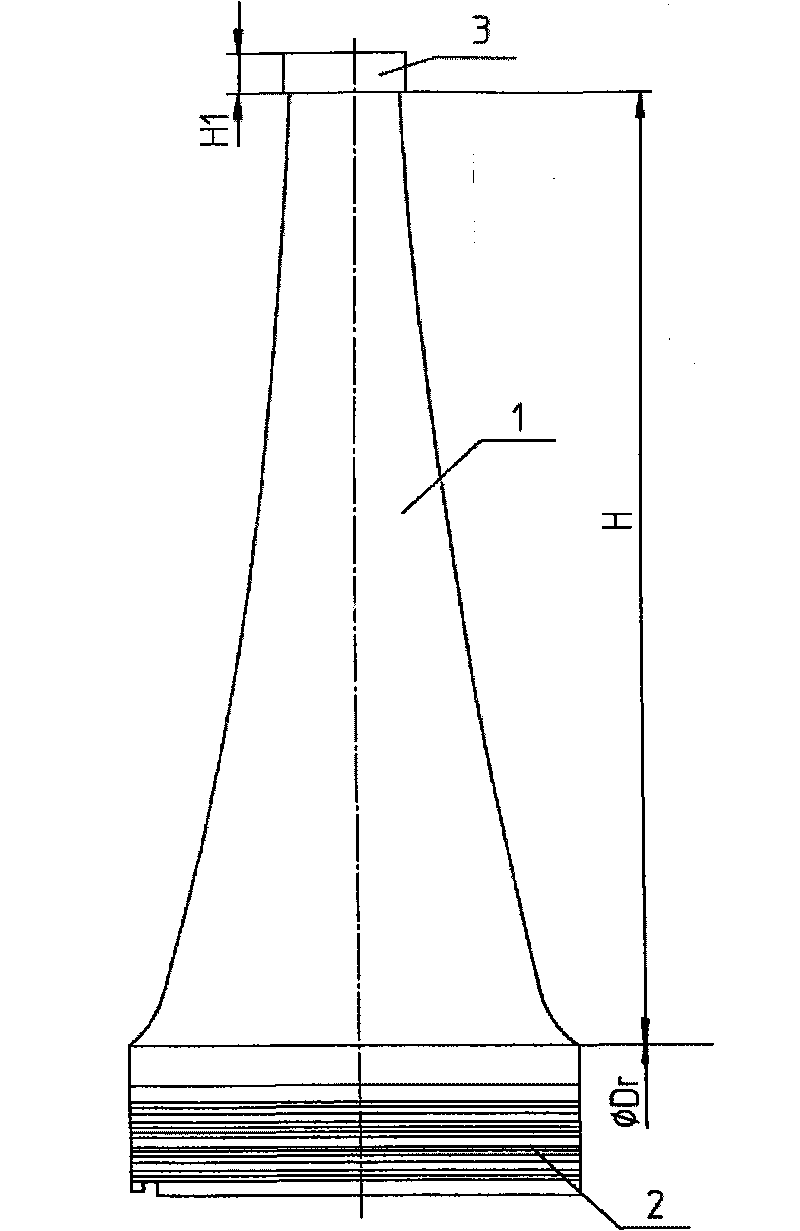

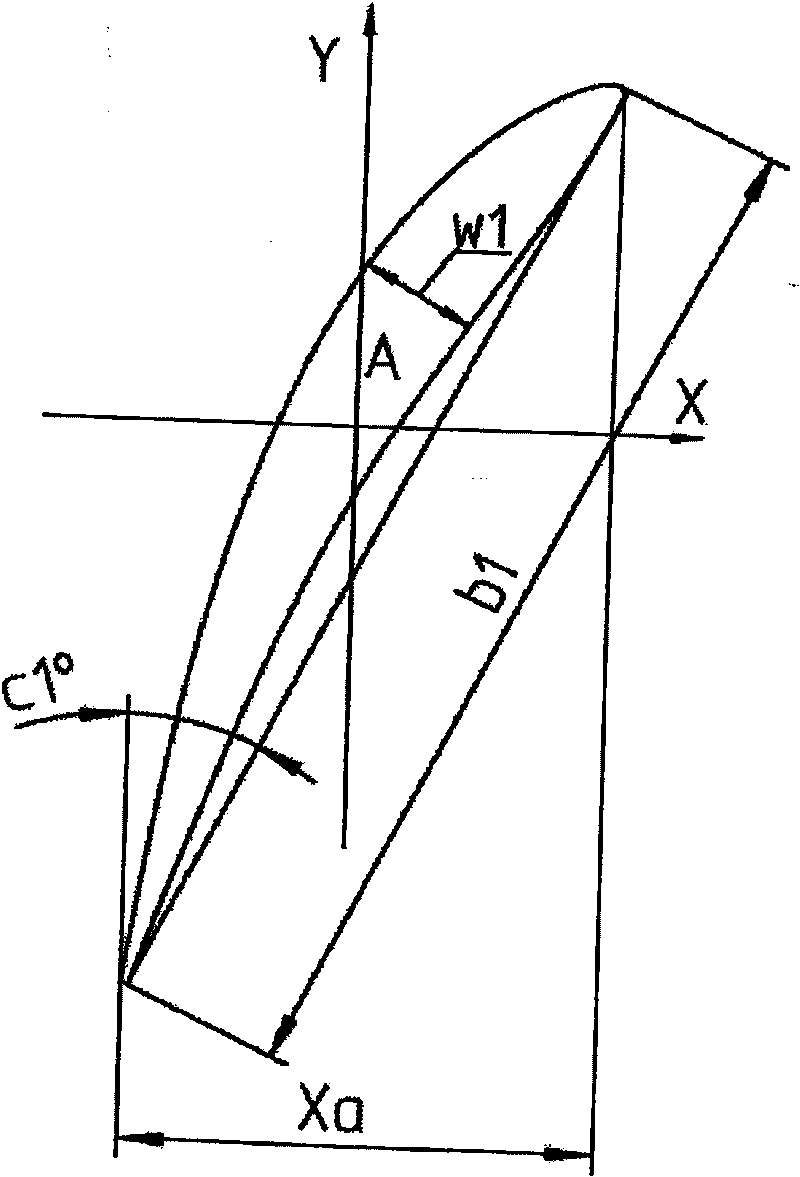

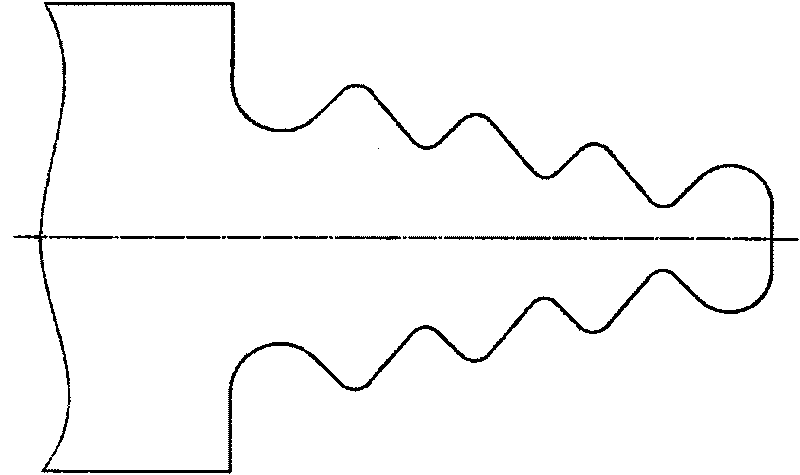

[0032] see Figure 1-Figure 4 : the present invention adopts stainless steel material, and is designed and manufactured into blade body 1, blade root 2 and blade crown 3 with integral structure according to this patent design, and blade body 1, blade root 2 and blade crown 3 three parts are to use the same high-strength performance stainless steel Manufactured as a whole. Among them, the airfoil 1 is a twisted structure with variable cross-section, and the width, thickness and cross-sectional area of the airfoil gradually decrease from the root to the top, and the transition is smooth. The moving blade is installed in the impeller groove on the outer circle of the rotating shaft through the blade root 2, and 70 blades are installed in each wheel groove. When the blades are installed in the impeller groove of the impeller, the final stage of the feed pump steam turbine is formed. .

[0033] The design carrier of the moving blade is an ultra-supercritical air-cooled 1000MW s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com