Heat insulating member with flexible positioning member and connecting member thereof

A thermal insulation component, flexible positioning technology, applied in the direction of thermal insulation, building components, building structure, etc., can solve the problems affecting the stability and service life of the thermal insulation system, easy to form cold bridges, affect the decorative effect, etc., to achieve excellent thermal radiation shielding Performance, Overall Stability Blocking, Effect of Excellent Wave Absorbing Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

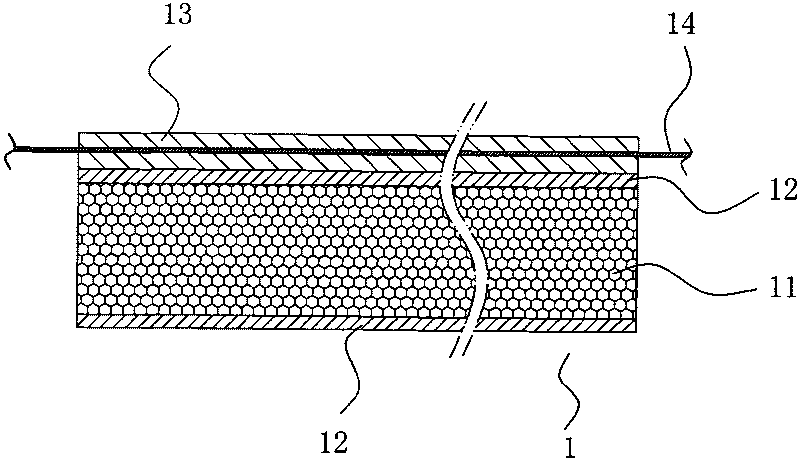

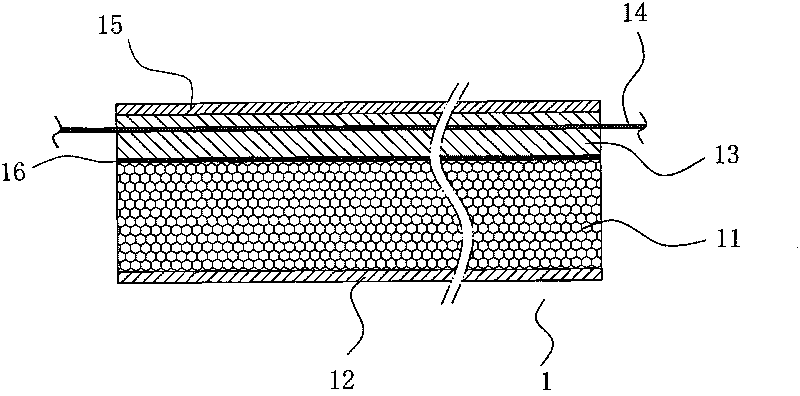

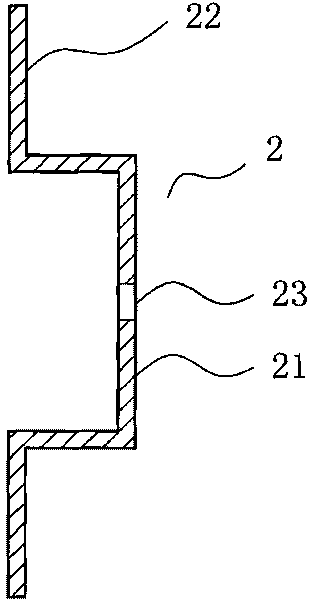

[0032] The present invention will be further described below with specific embodiment, see Figure 1-11 :

[0033] A thermal insulation component 1 with flexible positioning parts, a layer of waterproof layer 12 is impregnated on both sides (or one side) of the thermal insulation board 11, and outside the waterproof layer 11 on the other side (or both sides) of the thermal insulation board 11 A protective layer 13 is provided, and flexible fibers 14 extending outside the protective layer 13 (or outside the thermal insulation board 11 ) are arranged inside the protective layer 13 (or the thermal insulation board 11 ).

[0034] The aforementioned flexible fibers 14 are: flexible fiber bundles or flexible fiber webs 142 or flexible fiber ribs or flexible fiber strips 141 .

[0035] Above-mentioned flexible fiber 14 has two flexible fiber bands 141 or one layer of flexible fiber net 142 crossing in protective layer (or heat preservation board), and the protective layer 13 that ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com