Composite reinforcing method for combining soft foundation light well point pipe with plastic drainage plate

A technology of plastic drainage boards and light well points, which is applied in infrastructure engineering, soil protection, construction, etc. It can solve the problems of muddy sites, spring soil, and the inability to reduce the water content of the silt interlayer soil, and achieve the water content of the soil. The effect of balance, short construction period, and cost-effective improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific process steps of this construction method are as follows (dynamic consolidation takes dynamic compaction as an example):

[0033] Step 1. Excavate the drainage ditch

[0034] For a large area of soft ground, if the light well plastic drainage well point precipitation reinforcement technology is adopted, several small areas can be set up in the area to be reinforced. Generally, one small area is 5000-10000m 2 . Open ditches shall be excavated between residential quarters, and the open ditches of the residential quarters shall connect with each other to form a drainage network. A certain number of water collection wells shall be set at the junctions of open ditches, and the open ditch water shall be discharged into adjacent rivers by self-flow or forced drainage.

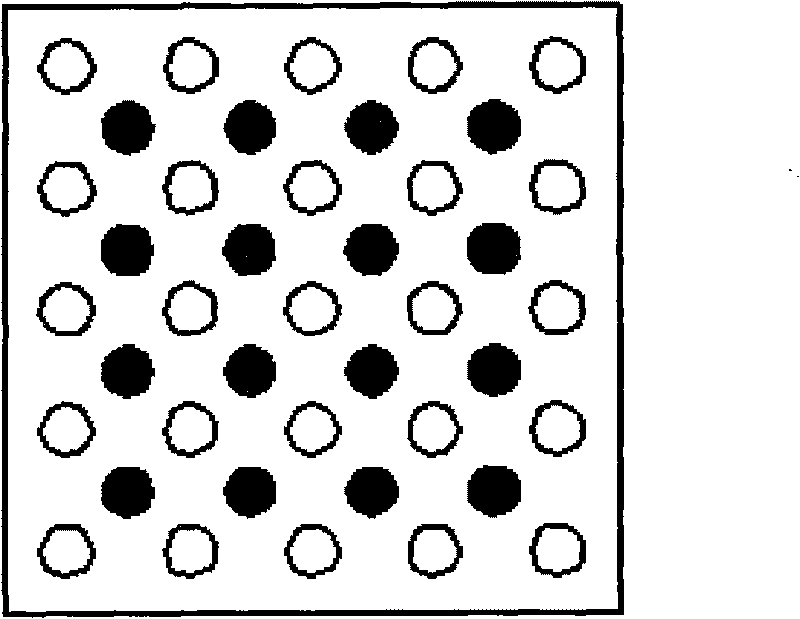

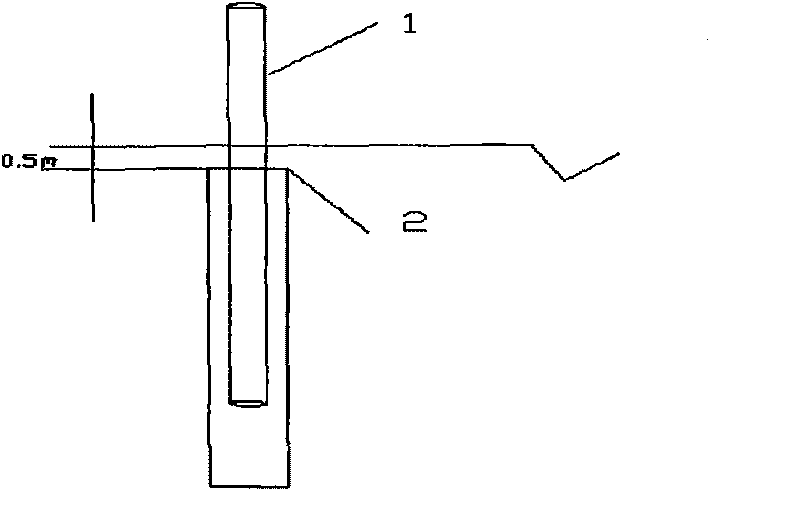

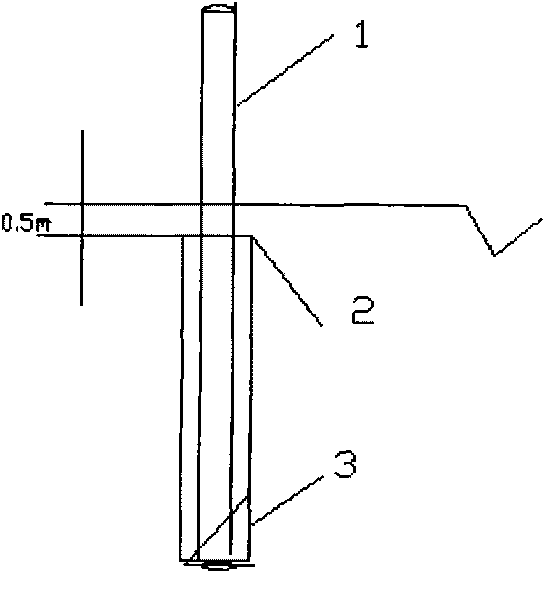

[0035] Step 2. Arrange the composite well point formed by the light well point pipe combined with the plastic drainage plate (referred to as the light well plastic drainage well point) and carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com