Preparation method of water-base epoxy resin sizing agent for carbon fiber

A water-based epoxy resin, epoxy resin curing technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of poor carbon fiber reinforcement, poor performance of emulsion sizing agent, and high cost, and achieve easy gluing. , low cost, good effect of enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

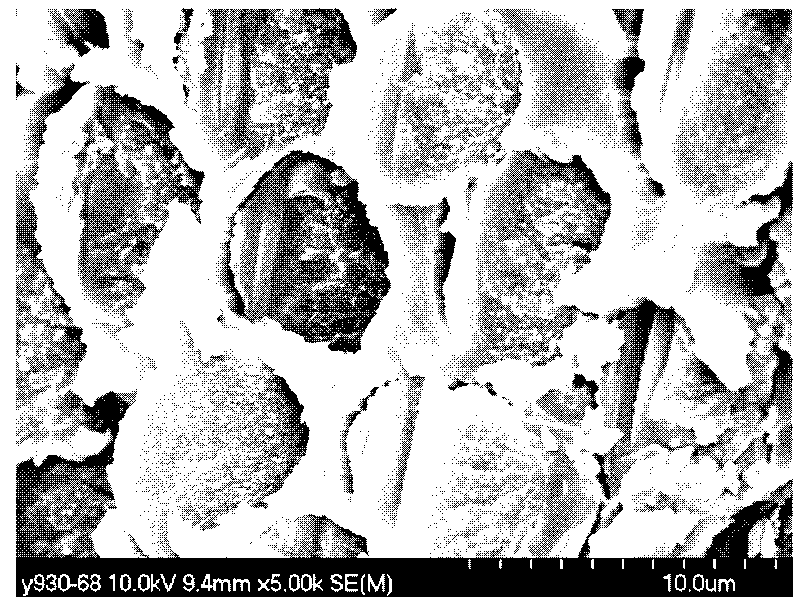

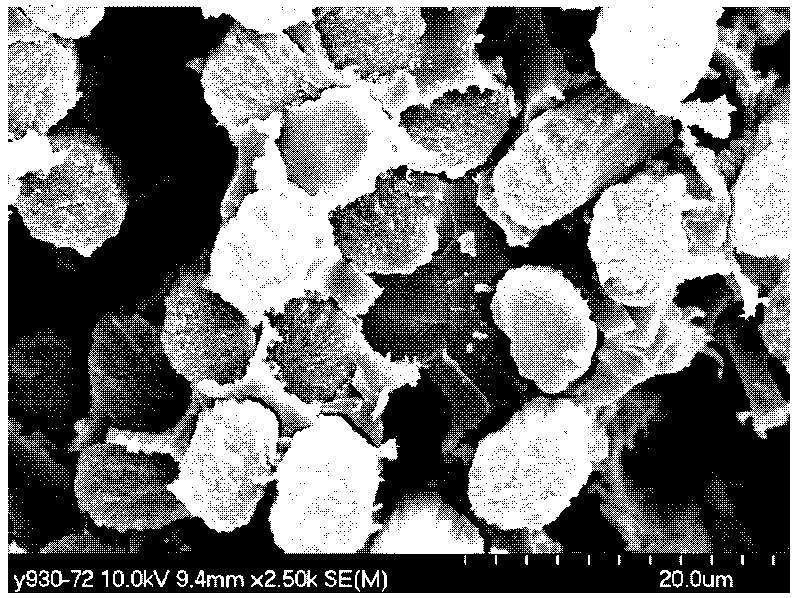

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: the preparation method of carbon fiber water-based epoxy resin sizing agent in this embodiment is realized by the following steps: one, add epoxy resin and water-based epoxy emulsifier by mass ratio 80:20 in the water bath of 70 ℃, then Place in a high-shear dispersing emulsifier, stir at a speed of 1500-16000r / min, and add deionized water dropwise until the phase transfer occurs in the mixed system, and then add deionized water dropwise to the solid content of the mixed system after 20-90 minutes 40% to 50%, continue to stir for 30 minutes to obtain water-based epoxy resin HIT-WE; 2. Add epoxy resin curing agent and water-based epoxy emulsifier in a water bath at 70°C in a mass ratio of 80:20, and then place In the high-shear dispersing emulsifier, stir at a speed of 1500-8000r / min and add deionized water dropwise, and then add deionized water dropwise after 3-5 hours until the solid content of the mixed system is 40%-50%. 3. Dilute the water-b...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is the preparation of water-based epoxy emulsifier in step one: the 250ml four-necked bottle equipped with agitator, reflux condenser and thermometer is placed in 80 ℃ water bath , then add bisphenol A epoxy resin and polyethylene glycol in a molar ratio of 1:1, and stir at a rate of 200 to 500r / min until molten state; heat up to 100°C, add bisphenol A epoxy resin and triphenylphosphine with 0.15% of the total mass of polyethylene glycol, and stirred at a rate of 200-500r / min for 6h, then pour the product into a watch glass to obtain a water-based epoxy emulsifier; put it into a desiccator for preservation . Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, stirring is performed at a rotational speed of 2000-10000 r / min. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com