Film-coating workpiece carrying device and film-coating method

A technology for carrying devices and workpieces to be plated, applied in optical components, sputtering plating, ion implantation plating, etc., can solve problems such as distortion, large residual stress, deformation, etc., to reduce adhesion stress, avoid distortion, The effect of reducing the slight deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The coated workpiece carrying device of the technical solution will be further described in detail below in conjunction with the accompanying drawings.

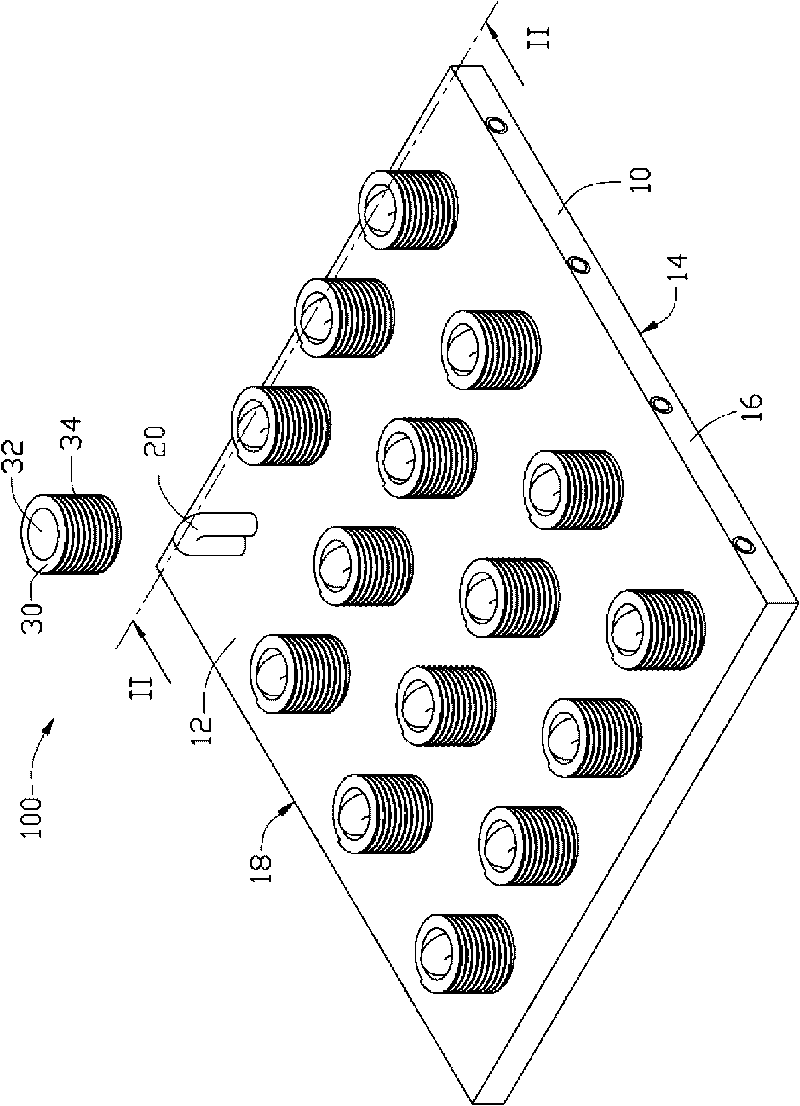

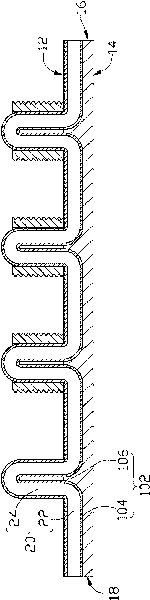

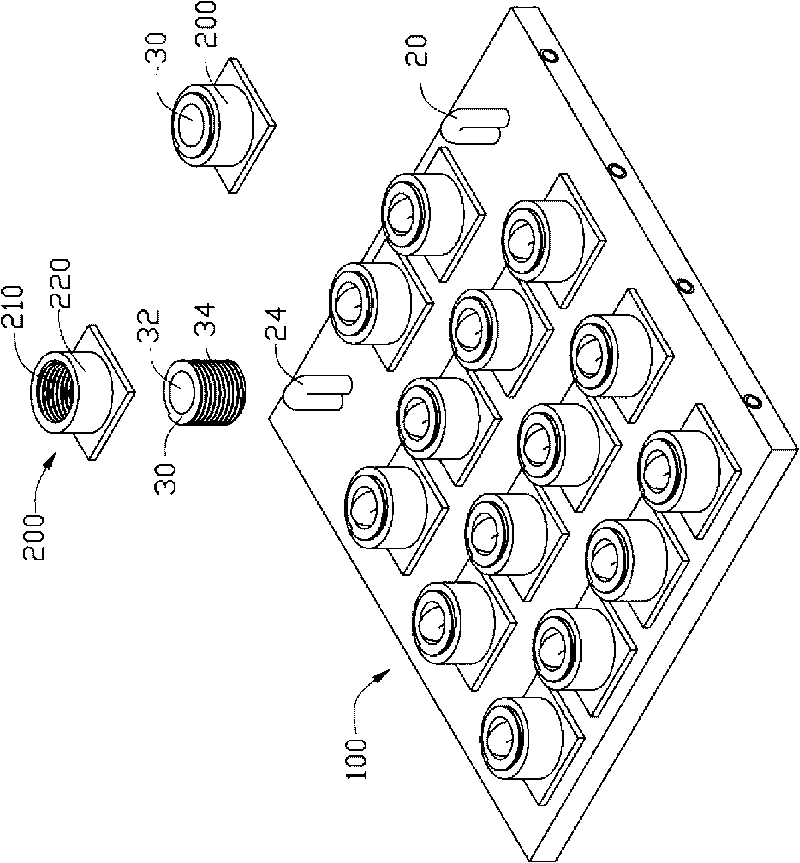

[0014] Please also refer to figure 1 and figure 2 , The coated workpiece supporting device 100 provided by the embodiment of the technical solution includes a chassis 10 , at least one cooling pipe 20 penetrating inside the chassis 10 , and a plurality of holders 30 . The cooling pipe 20 is fixed on the chassis 10 , and the holder 30 is arranged on the cooling pipe 20 , and the holder 30 is used to fix the workpiece to be coated so as to coat the workpiece to be coated.

[0015] The chassis 10 is a rectangular flat structure, and the chassis 10 has a first surface 12 , a second surface 14 , and a first side 16 and a second side 18 connected between the first surface 12 and the second surface 14 . The first surface 12 is parallel to the second surface 14 , wherein the first surface 12 is a bearing surface. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com