Double-phase stainless steel with high nitrogen, high chromium and low nickel

A technology of duplex stainless steel and high chromium, applied in the field of steel alloy materials, can solve the problems that Cr29Ni2 products have not been reported, and achieve the effect of improving high-temperature thermoplasticity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0041] Select high-quality C, Cr, Ni, Fe and other metal raw materials, smelt them in a 10kg induction furnace with a controlled atmosphere, cast them into small steel ingots, and then forge them into required products for various analysis. A#, B#, C# and D# are samples of high-nitrogen, high-chromium, low-nickel duplex stainless steel smelted in Examples 1-4, respectively, and UNS32906 is a sample of UNS32906 duplex stainless steel in standard ASTMA789A789M-05b.

[0042] 1. Chemical composition

[0043] Table 5 shows the chemical composition of the finished high-nitrogen, high-chromium and low-nickel duplex stainless steel products smelted in various examples, where the amounts of B and Ce are added amounts.

[0044] Table 5 Chemical Composition of Finished Products of High Nitrogen, High Chromium and Low Nickel Duplex Stainless Steel (%)

[0045] serial number

[0046] *Indicates the amount added.

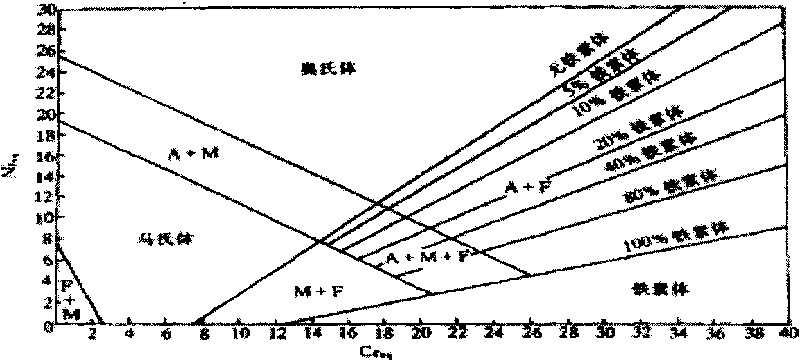

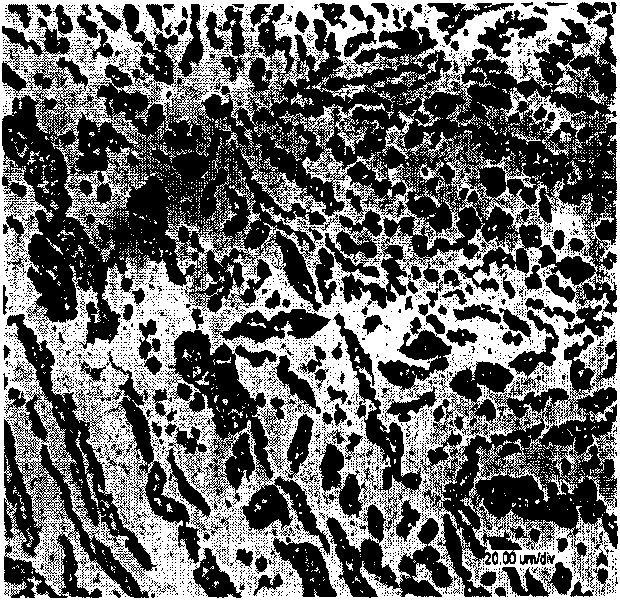

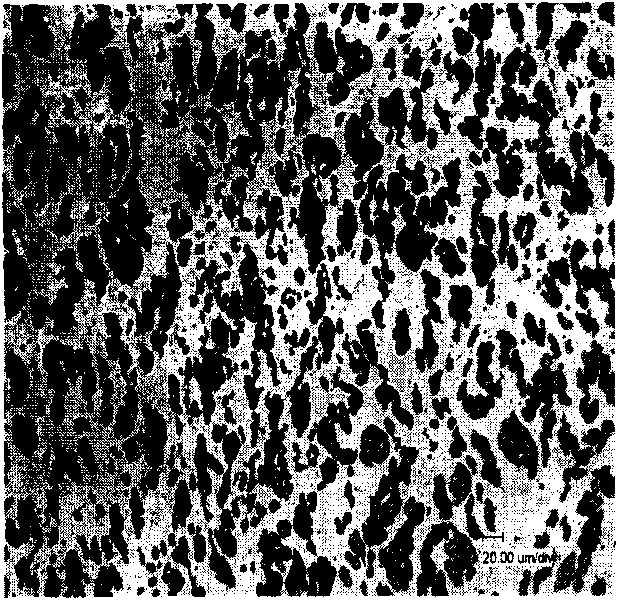

[0047] 2. Phase structure at different temperatures

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com