Production process for extracting, separating and purifying potentilla flavone

A technology of separation and purification and Potentilla, which is applied in the fields of sugar derivatives, sugar derivatives, organic chemistry, etc., and can solve problems such as difficulty in ensuring effective ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

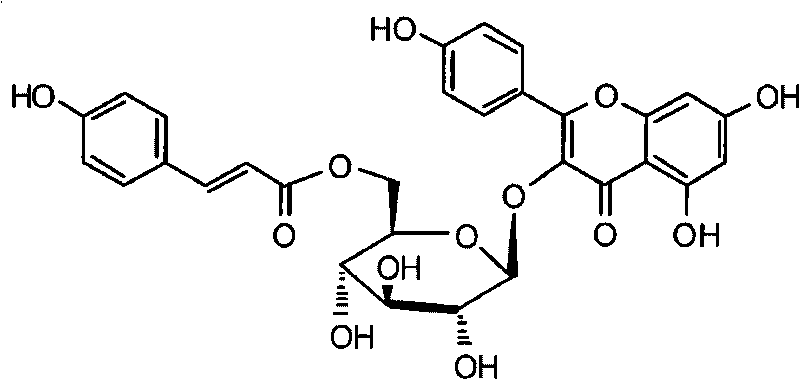

Image

Examples

Embodiment 1

[0022] Take 25kg of naturally dried and crushed Chinese herbal Potentilla Potentilla produced in Ji County, Tianjin, add 200kg of 60% ethanol to soak overnight, heat and reflux for extraction for 1.5 hours, filter, then reflux extract with 150kg of 60% ethanol for 1.5 hours, filter; then add 150kg of 60% ethanol to extract Reflux extraction for 1.5 hours, combine the three extracts, and concentrate to obtain 4.6 kg of extract, the content of flavonoids in Potentilla spinach was determined to be 4.050‰ by HPLC.

[0023] The above extract was dissolved in 46kg 30% ethanol, fully stirred, centrifuged at 3000r / min for 10min, the supernatant was taken, separated with 20-60 mesh AB-8 macroporous adsorption resin column, 10BV was loaded, and the adsorption flow rate was 2BV / h. Then eluted with 30% ethanol at a mass concentration of 3BV, 60% ethanol at a mass concentration of 5BV, and 95% ethanol at a mass concentration of 4BV, and the elution flow rate was 2BV / h, and the 60% ethanol e...

Embodiment 2

[0026] Take 30kg of naturally dried and pulverized traditional Chinese medicine Potentilla from Jixian County, Tianjin, add 240kg of 60% ethanol to soak overnight, heat and reflux for extraction for 1.5 hours, filter, then reflux with 180kg of 60% ethanol for 1.5 hours, filter; then reflux with 180kg of 60% ethanol After extracting for 1.5 hours, the three extracts were combined and concentrated to obtain 5.4 kg of extract, in which the flavonoid content of Potentilla flavonoids was 4.022‰. Dissolve in 54kg30% ethanol, stir well, centrifuge at 3000r / min for 10min, take the supernatant, separate it with 20-60 mesh AB-8 macroporous adsorption resin column, load 10BV, the adsorption flow rate is 2BV / h, and then sequentially with 3BV Elute with 30% ethanol at a mass concentration, 60% ethanol at a mass concentration of 5BV, and 95% ethanol at a mass concentration of 4BV. Liquid A (the content of flavonoids in the extract is 3.4%). Dissolve the resulting suspension in an equal vol...

Embodiment 3

[0029] Take 35kg of naturally dried and pulverized traditional Chinese medicine Potentilla from Jixian County, Tianjin, add 280kg of 60% ethanol to soak overnight, heat and reflux for extraction for 1.5 hours, filter, then reflux with 210kg of 60% ethanol for 1.5 hours, filter; then reflux with 210kg of 60% ethanol After extracting for 1.5 hours, the three extracts were combined and concentrated to obtain 6.1 kg of liquid extract, of which the flavonoid content of Potentilla chinensis was 4.502‰. Dissolve in 61kg of 30% ethanol, stir well, centrifuge at 3000r / min for 10min, take the supernatant, separate it with AB-8 macroporous adsorption resin column, load 10BV, the adsorption flow rate is 2BV / h, and then sequentially use 3BV mass concentration 30% Ethanol, 5BV mass concentration 60% ethanol, 4BV mass concentration 95% ethanol elution, elution flow rate 2BV / h, collect 60% ethanol eluent, concentrate under reduced pressure to no alcohol smell, the suspension A obtained (the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com