Device and method for preparing high-purity nano polyaluminium chloride with high efficiency, energy saving and environmental protection

A polyaluminum chloride, high-efficiency and energy-saving technology, applied in the fields of aluminum chloride, aluminum halide, chemical industry, etc., to reduce costs, reduce pollution, and improve reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

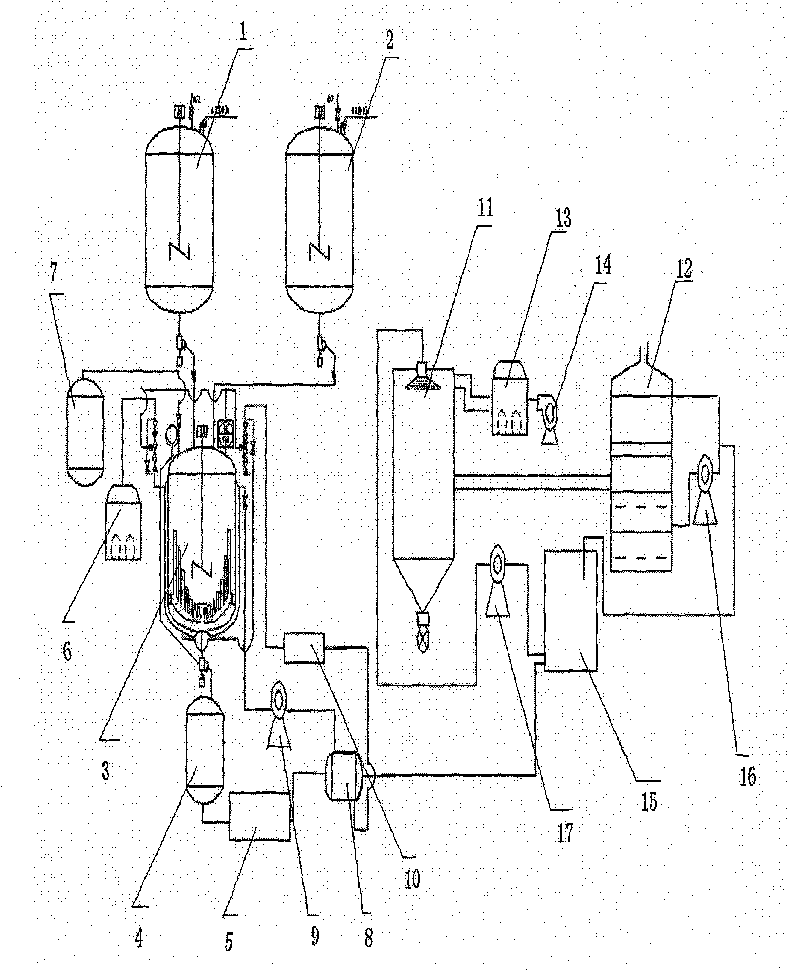

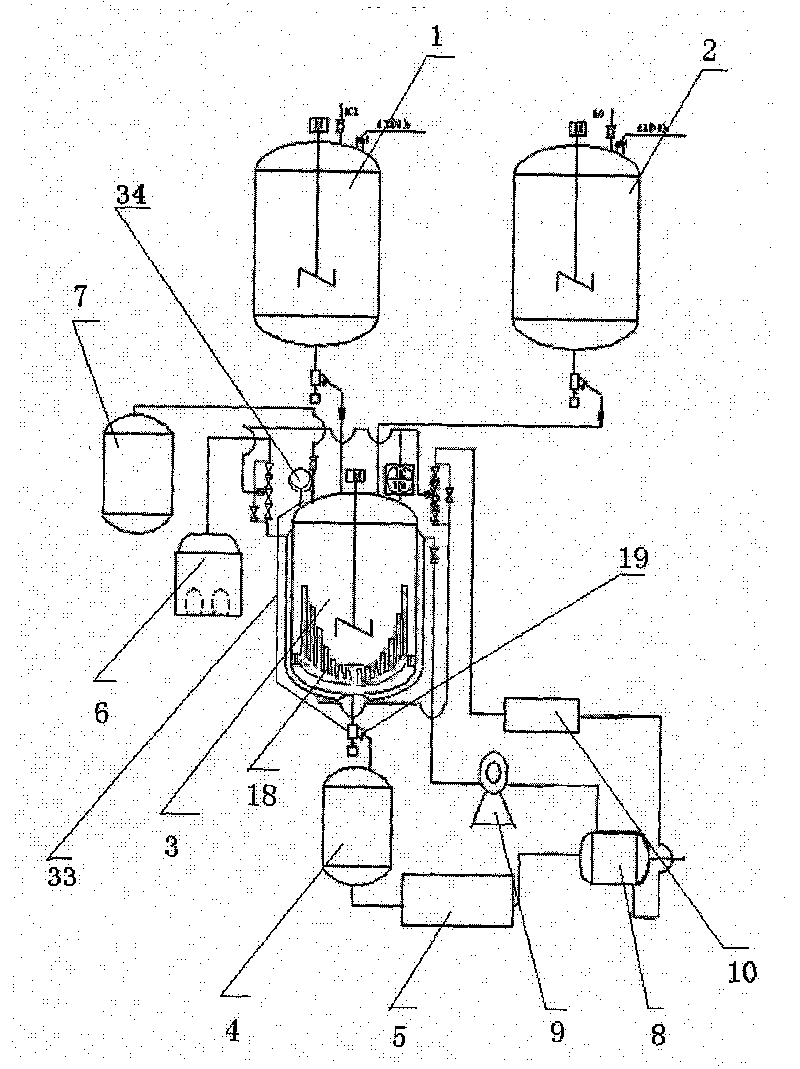

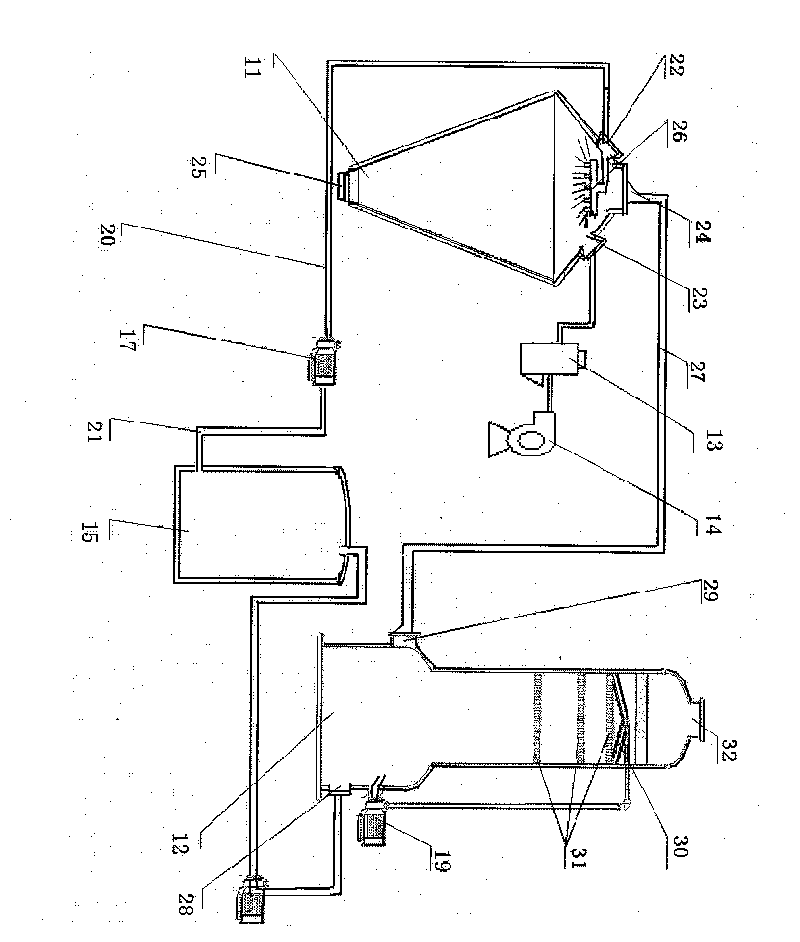

[0017] As shown in the accompanying drawings: a high-purity nano-polyaluminum chloride high-efficiency, energy-saving and environment-friendly preparation device is composed of a liquid material generating part and a liquid material drying part. The material concentration part is composed of the reaction kettle for liquid material generation, which is a high-efficiency reaction kettle (3) for temperature measurement, and the heat energy of the liquid material concentration part for the membrane distillation device (8) is clamped in the high-efficiency reaction kettle (3) for temperature measurement. The waste heat of the jacket circulating water is obtained, and the drying part of the liquid material is provided with a drying tower (11) and a tail gas absorption tower (12). The tail gas absorption tower (12) is equipped with a tail gas waste material recovery and waste heat reuse device.

[0018] The above-mentioned liquid material generation part is provided with batching kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com