Automatic forewheel wind deflector and wind guiding structure

A technology of air guide structure and air guide plate, which is applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., and can solve the problem of reducing wind resistance, large air resistance at the bottom of the vehicle, and the lack of wind guide and drag reduction effect of the air guide plate. problem, to achieve the effect of reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

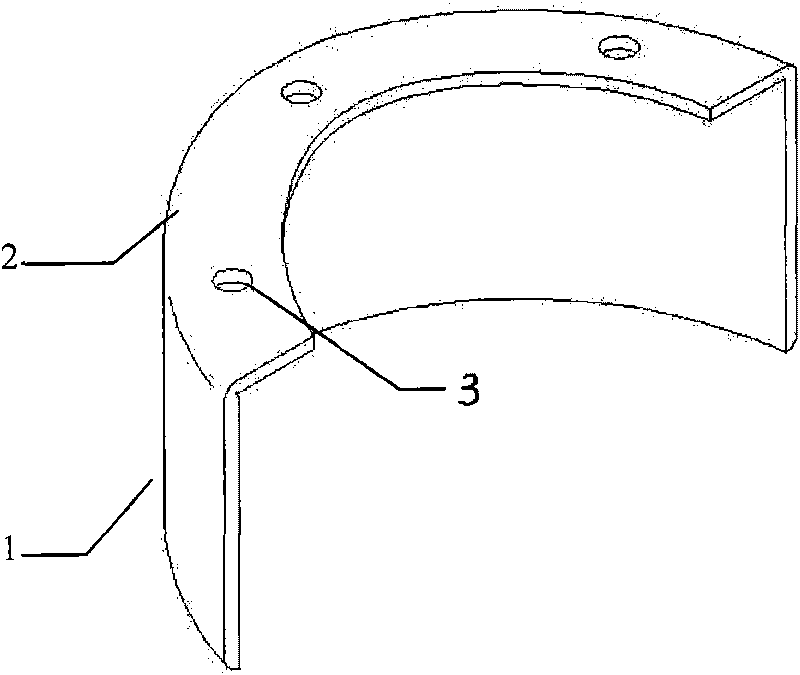

[0024] see figure 1 and figure 2 , the wind deflector is usually made of plastic and consists of a deflector part 1 and an installation part 2 .

[0025] The deflector part 1 is the main part, occupying most of the area of the wind deflector, and has an arc-shaped structure in the transverse direction, with a height of 10 mm to 60 mm.

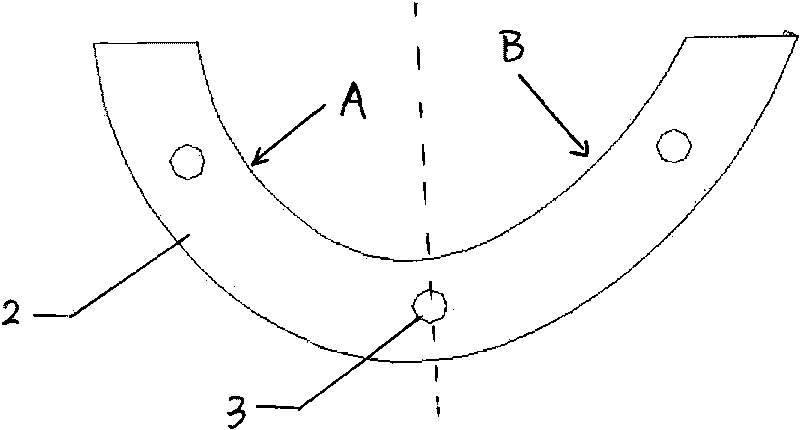

[0026] The arc-shaped structure of the diversion part 1 is not symmetrical. The bending arc of the part A on the outer side of the vehicle (that is, the side that is farther away from the center plane of the vehicle after installation) is more curved than the part B on the inner side of the vehicle (that is, the side that is closer to the center plane of the vehicle). The arc on the side of the wheel should be large. The function of this asymmetric structure is to guide the airflow outside the guide part 1 to blow to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com