Dust self-discharging filter

An air filter and dust technology, which is applied in the direction of fuel air filter, combustion air/combustion-air treatment, machine/engine, etc., can solve the problems of filter clogging, passage, and engine failure to deliver oil normally, and achieve Effects of avoiding clogging and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

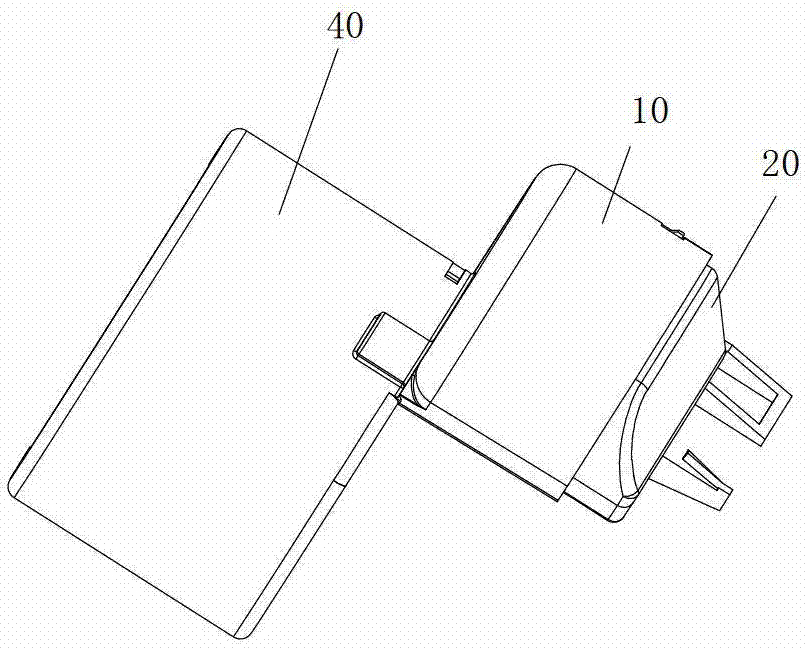

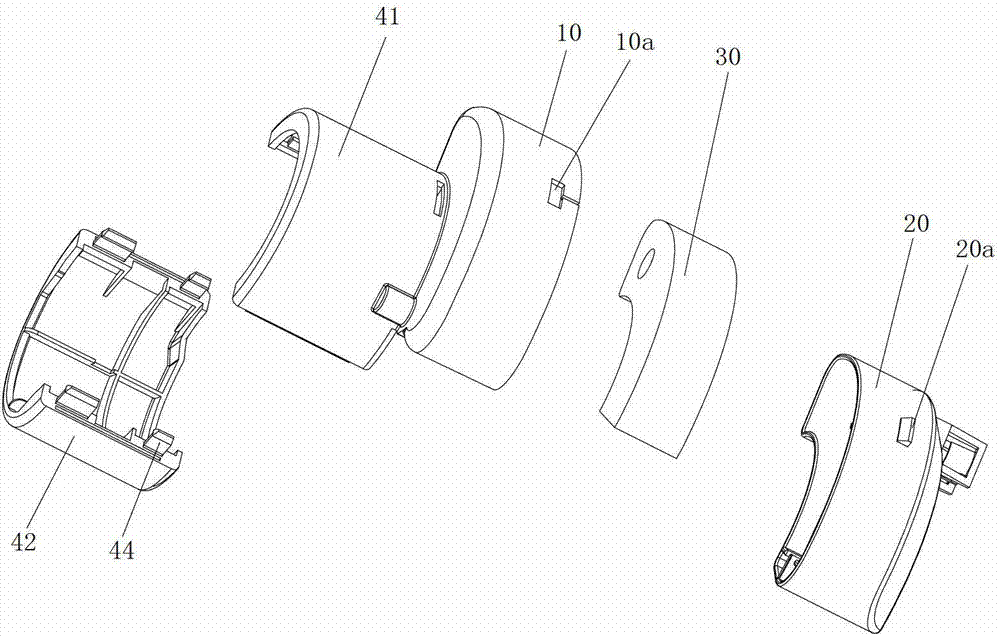

[0041] refer to figure 1 and figure 2 , The self-unloading dust air filter of the present invention is mainly made up of four major parts of a box cover 10, a box body 20 with a cavity, a filter 30 and a connecting device 40, and each part is made of plastic. The structure and function of each part are described in detail below:

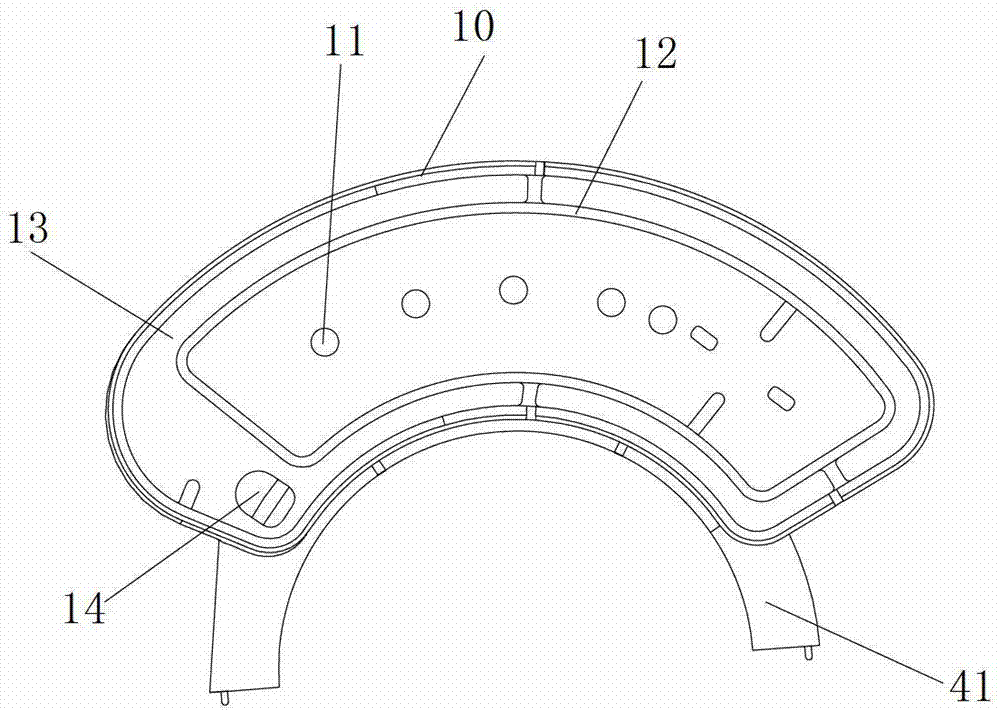

[0042] refer to image 3 and Figure 4 , the box cover 10 is used to cover the cavity of the box body 20 and is fastened as one with the box body, and the box cover 10 is waist-shaped. A locking hole 10 a is provided on the side wall of the box cover 10 . At least one positioning column 11 is provided on the inner top wall surface of the box cover opposite to the mouth of the box cover. These positioning columns are used to position the filter 30 and prevent the filter 30 from being displaced when it is vibrated. On the lid 10, an annular protrusion 12 is arranged on the inner top wall surface opposite to the mouth of the lid, and the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com