Magnetic Stirring and Liquid Level Regulating Device for Light-curing Rapid Prototyping Ceramic Slurry

A technology of ceramic slurry and magnetic stirring, which is applied in clay preparation devices, chemical instruments and methods, clay processing equipment, etc. , to ensure uniformity and increase the effect of the working surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

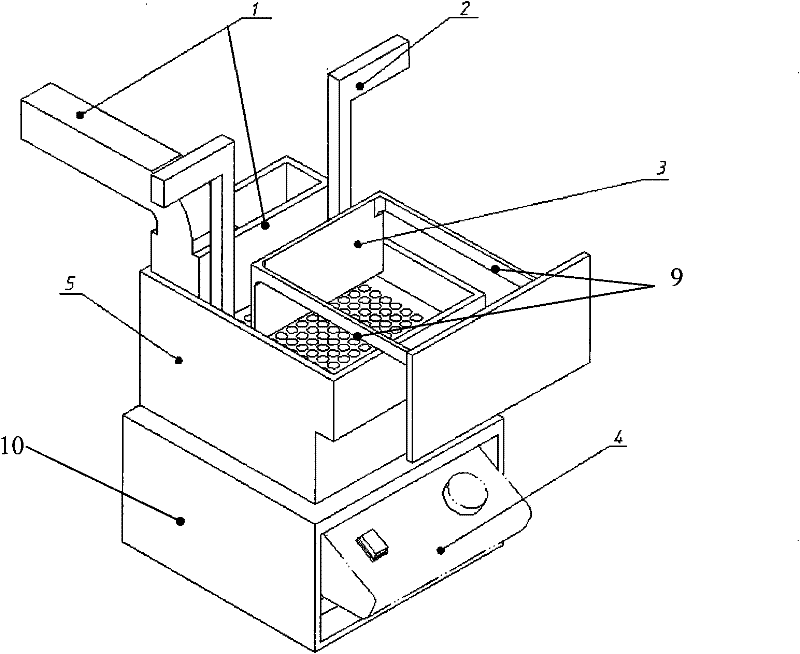

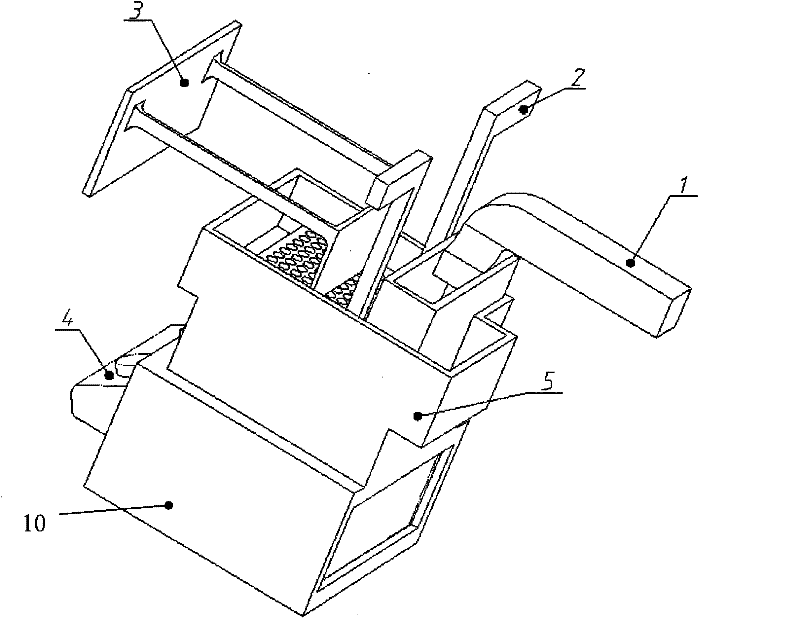

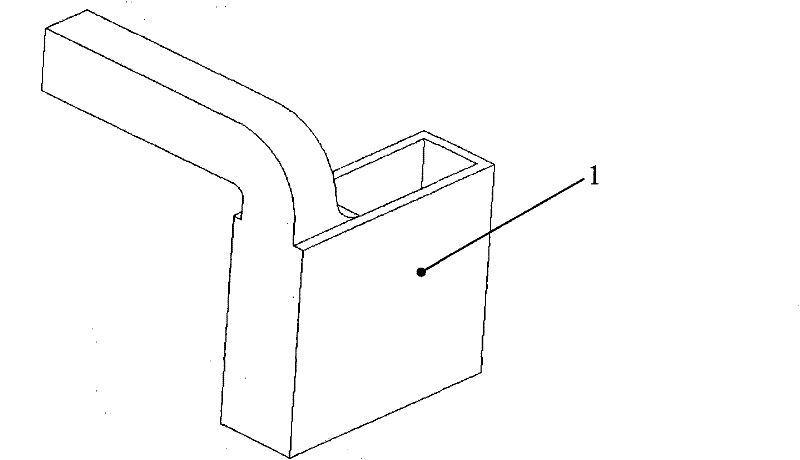

[0024] The overall assembly diagram of the present invention is as figure 1 and figure 2 As shown, the light-curing rapid prototyping ceramic slurry magnetic stirring and liquid level regulating device includes a rectangular slurry tank 5 and a mesh plate 2 and a scraper 3 arranged in the slurry tank 5. In addition, the slurry tank 5 A floating block 1 that can move vertically up and down is also provided, and a magnetic stirrer 4 is provided below the slurry tank 5 . The specific structure of the slurry tank 5 of the present invention is as Figure 5 and Figure 6 As shown, there is a circular blind groove 6 for setting the magnetic stirrer 4 rotors on the bottom of the inner groove. In order to ensure the magnetic stirring effect and facilitate the start of the rotor of the magnetic stirrer 4, the circular blind groove 6 is tangent to both sides of the slurry ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com