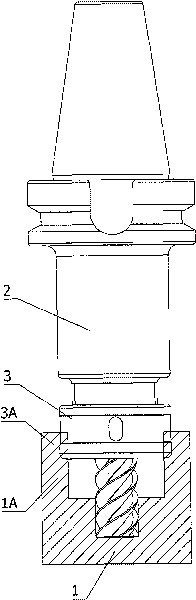

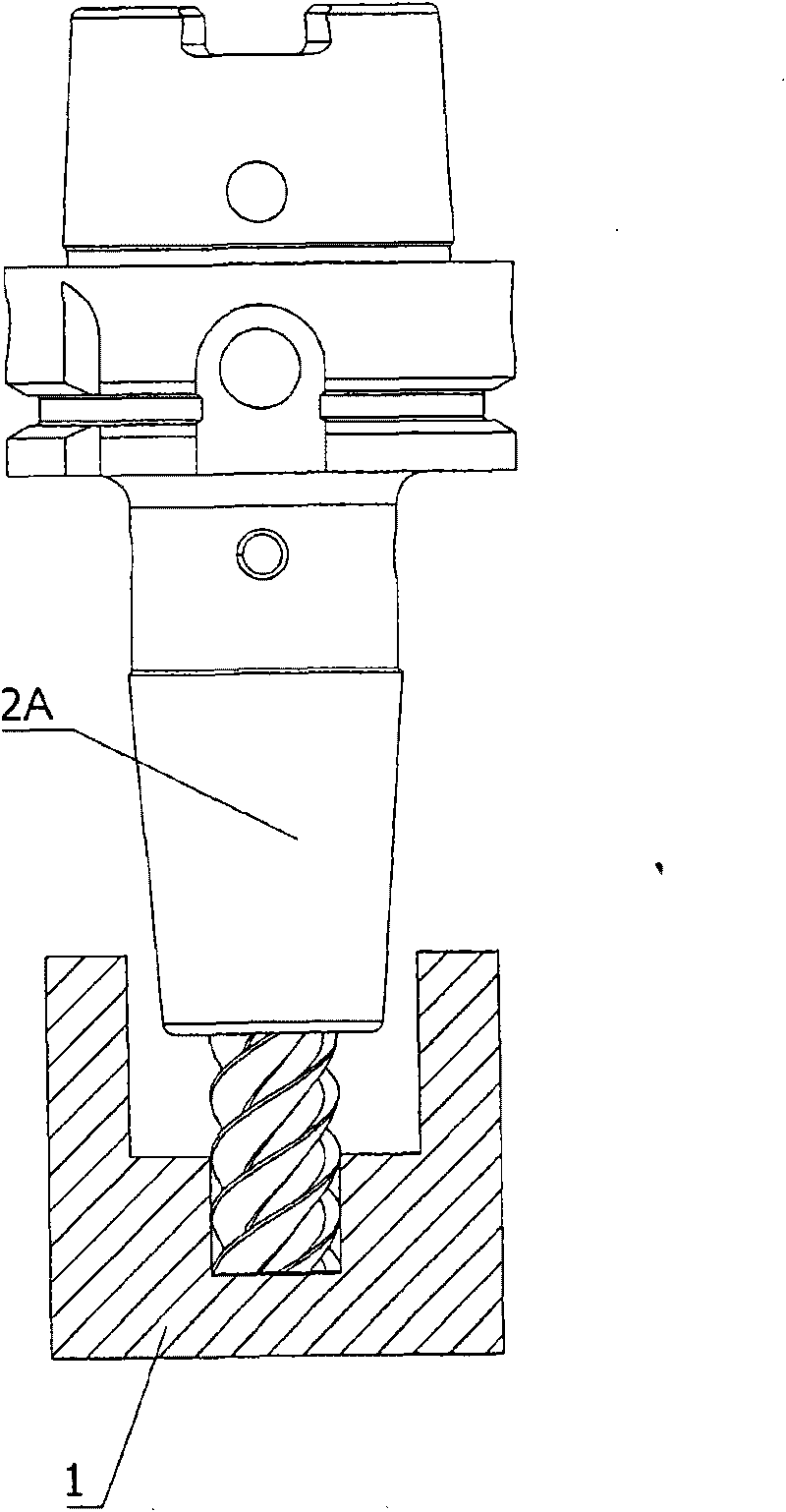

Worm-gear type collet chuck locking mechanism

A technology of worm gear and locking mechanism, applied in the direction of clamping, metal processing mechanical parts, support, etc., can solve the problem of poor universality of the tool holder, and achieve the effect of reliable clamping and fixing, easy production, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

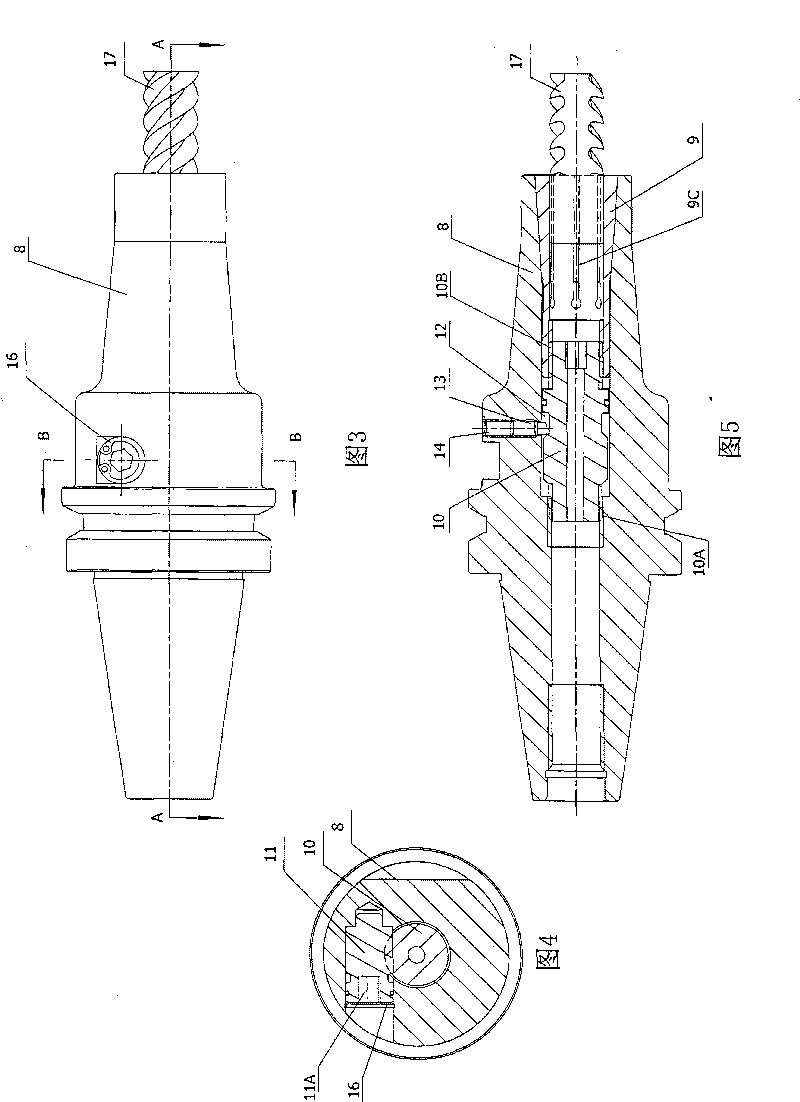

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings of the description.

[0018] Such as Figure 4 , Figure 5 As shown, a kind of worm gear type collet locking mechanism, comprises the body 8 that the right half part is shaped on cavity (as can be seen from the figure, the left end of this cavity is cylindrical, and the right end is conical); A tapered collet 9 matched with the body is arranged in the cavity (the tool is clamped in the clamping cavity of the tapered collet); a worm wheel 10 is also arranged in the cavity (the worm wheel is coaxial with the body installation), the left end of the worm wheel 10 is threadedly engaged with the body (at 10A among the figures), and the right end of the worm wheel 10 is threaded at the left end of the tapered collet 9 (at 10B among the figures); the body 8 Also be provided with a worm screw 11 that cooperates with described worm gear on it.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com