An Improved Auxiliary Clamping Mechanism for Five-Axis Rotary Machining of Blade Profiles

A technology of blade and top tightness, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as easy to leave obvious vibration lines on the processing surface, affect the milling efficiency of the blade, and the blade body is easy to shake, etc., to achieve improved Effects of surface quality, increased rigidity, and reduction in machining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

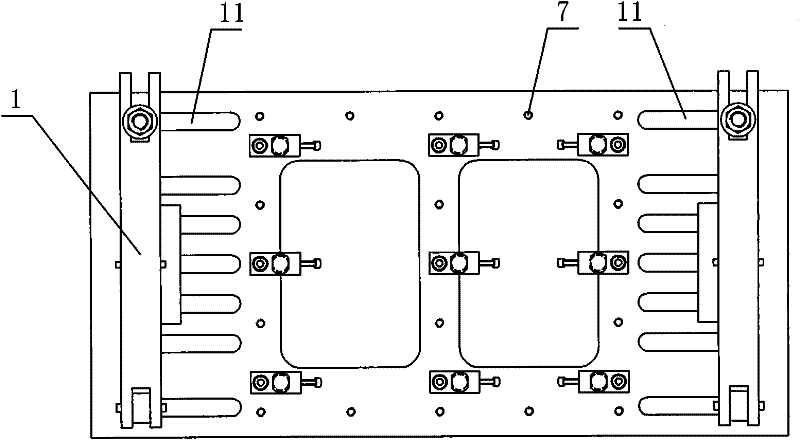

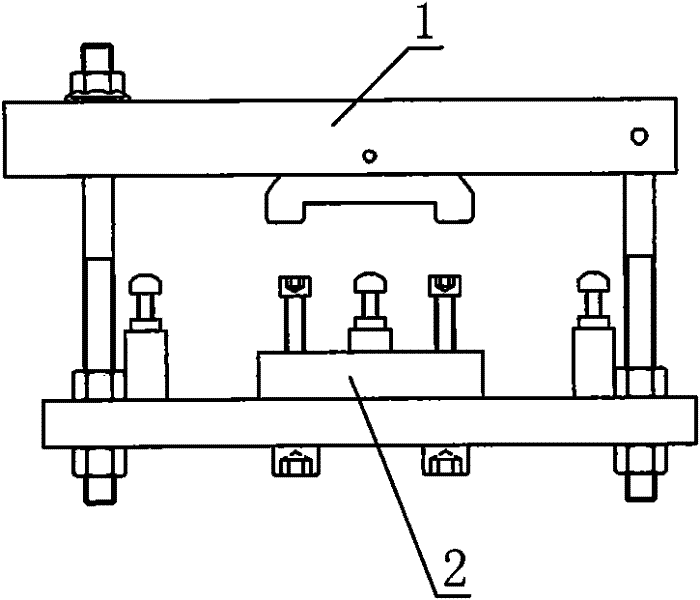

[0011] See figure 1 , figure 2 , image 3 and Figure 4 , the present invention includes a bottom plate 6, a hinge plate 1 and a positioning block 2 are installed on both sides of the bottom plate 6, and a spring clamping device 3 is installed on the bottom plate 6. There are horizontal sliding grooves 11 on both sides of the bottom plate 6; the hinge plate 1 and the positioning block 2 are installed in the horizontal sliding groove 11; the spring tensioning device 3 is provided with multiple; the spring tensioning device 3 is fixed on the bottom plate 6 by screws. Inside the hole 7; the ejector rod 8 is installed in the spring tightening device 3; the spring 9 is embedded between the bottom of the ejector rod 8 and the spring tightening device 3; the ejector rod 8 is fixed to the spring tightening device 3 through the side tightening screw 5 There is a threaded hole 10 on the top of the ejector rod 8; a jacking screw 4 is installed in the threaded hole 10; a corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com