Single-disk reaming method of high-pressure rotor labyrinth disk

A high-pressure rotor and grate technology, which is applied in the field of machining, can solve the problems of high aperture size accuracy, long cutting depth, and difficult processing, and achieves the effect of increasing the number of maintenance uses, reducing the cost of tool use, and increasing the number of repairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The diameter of the machining hole is 10.5mm

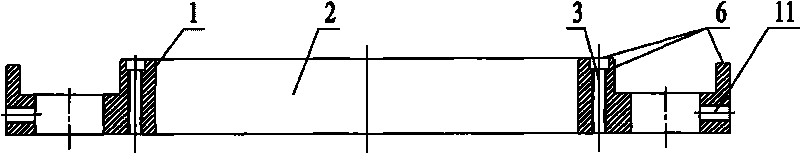

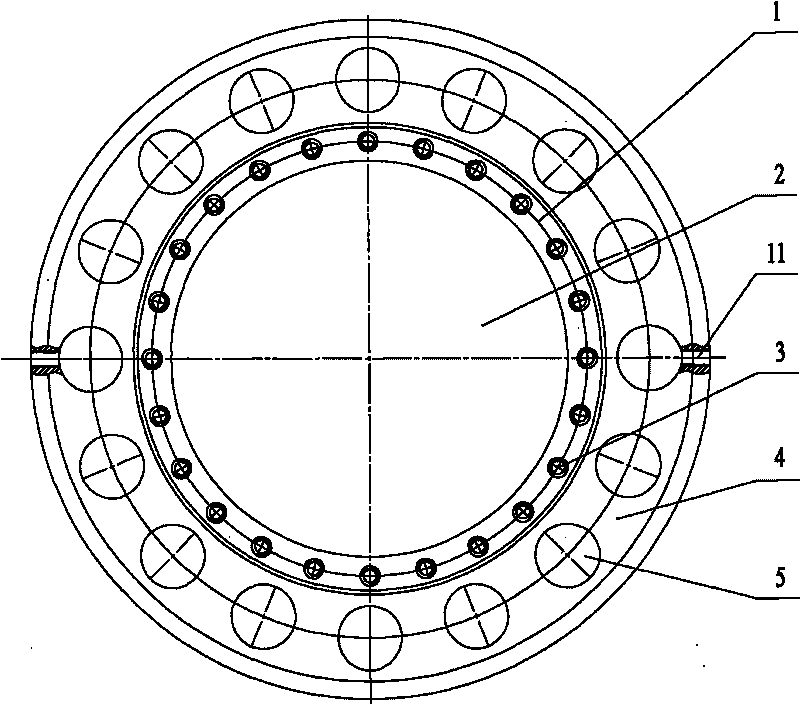

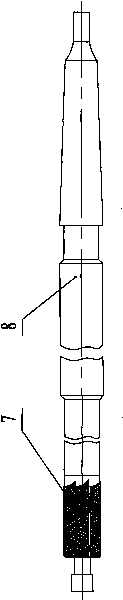

[0027] High-pressure rotor grate disc single disc reaming method, the grate disc 9 is separately fixed on the fixture 10 to ensure that the single disc reaming is carried out under the condition that the axial deformation of the single grate disc 9 is consistent with the assembly state, and the high-pressure rotor grate disc The procedure for reaming a single disc of disc 9 is as follows:

[0028] 1. Assemble the grate toothed disc to be processed on the fixture separately, use a torque wrench and process bolts to press the grate toothed disc through the bolt holes on the grate toothed disc, and the pressing torque is 20N. The amount of deformation is consistent with the assembly state;

[0029] 2. Install the jig equipped with the grate tooth plate on the radial drilling machine, use the dial gauge to align it, so that the plane runout of A surface is ≤0.02mm, and press it with bolts;

[0030] 3. Remove eve...

Embodiment 2

[0037] Embodiment 2: The diameter of the machining hole is 10.8mm

[0038] High-pressure rotor grate disc single disc reaming method, the grate disc 9 is separately fixed on the fixture 10 to ensure that the single disc reaming is carried out under the condition that the axial deformation of the single grate disc 9 is consistent with the assembly state, and the high-pressure rotor grate disc The procedure for reaming a single disc of disc 9 is as follows:

[0039] 1. Assemble the grate toothed disc to be processed on the fixture separately, use a torque wrench and process bolts to press the grate toothed disc through the bolt holes on the grate toothed disc, and the pressing torque is 20N. The amount of deformation is consistent with the assembly state;

[0040] 2. Install the jig equipped with the grate tooth plate on the radial drilling machine, use the dial gauge to align it, so that the plane runout of A surface is ≤0.02mm, and press it with bolts;

[0041] 3. Remove eve...

Embodiment 3

[0048] Embodiment 3: The diameter of the machining hole is 11.1mm

[0049] High-pressure rotor grate disc single disc reaming method, the grate disc 9 is separately fixed on the fixture 10 to ensure that the single disc reaming is carried out under the condition that the axial deformation of the single grate disc 9 is consistent with the assembly state, and the high-pressure rotor grate disc The procedure for reaming a single disc of disc 9 is as follows:

[0050] 1. Assemble the grate toothed disc to be processed on the fixture separately, use a torque wrench and process bolts to press the grate toothed disc through the bolt holes on the grate toothed disc, and the pressing torque is 20N. The amount of deformation is consistent with the assembly state;

[0051] 2. Install the jig equipped with the grate tooth plate on the radial drilling machine, use the dial gauge to align it, so that the plane runout of A surface is ≤0.02mm, and press it with bolts;

[0052] 3. Remove every...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com