Method for preparing ammonia nitrogen sorbent by utilizing abandoned strawberry leaves and application of sorbent

A strawberry leaf and adsorbent technology, applied in the field of water pollution treatment, can solve problems such as complicated process, secondary pollution, and high cost, and achieve the effects of high adsorption efficiency, low cost, and simple and easy pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

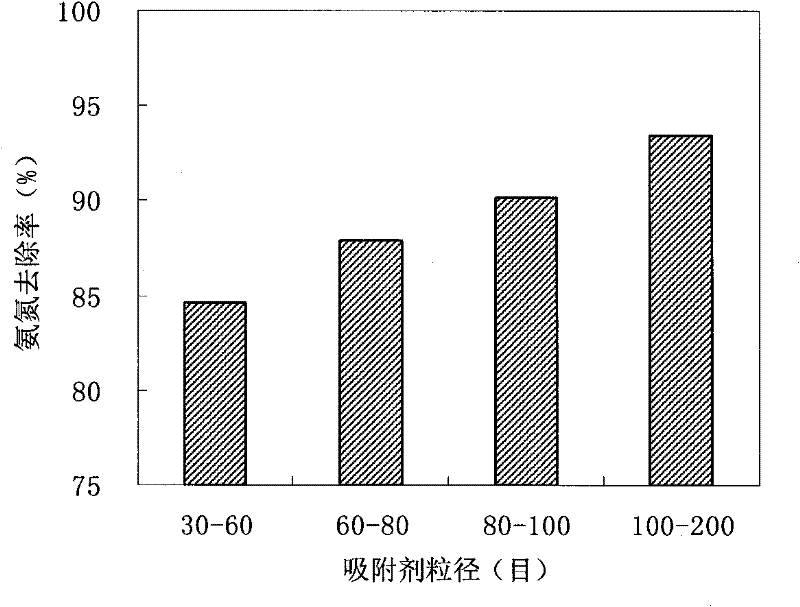

[0016] Strawberry leaves were collected from Jurong Strawberry Garden in Jiangsu Province, washed three times with tap water to remove dust and soluble impurities on the leaf surface, and then dried indoors in the shade to remove water droplets on the leaf surface. The strawberry leaf after drying is earlier at 105 DEG C after killing green for 15 minutes, then baked at 70 DEG C for 10 hours to dry. The dried strawberry leaves are mechanically pulverized, and then sieved into 30-60 meshes with a standard sieve. Add the prepared adsorbent at a dose of 8g / L to an aqueous solution containing 25mg / L of ammonia nitrogen, shake at room temperature at 250r / min, and shake for 24 hours. The results show that the removal rate of ammonia nitrogen in this state is 84.6%. Under the same conditions, changing the particle size of the adsorbent to 60-80 mesh, 80-100 mesh and 100-200 mesh respectively, the obtained removal rates were 87.9%, 90.1% and 93.4%, respectively.

[0017] It can be s...

Embodiment 2

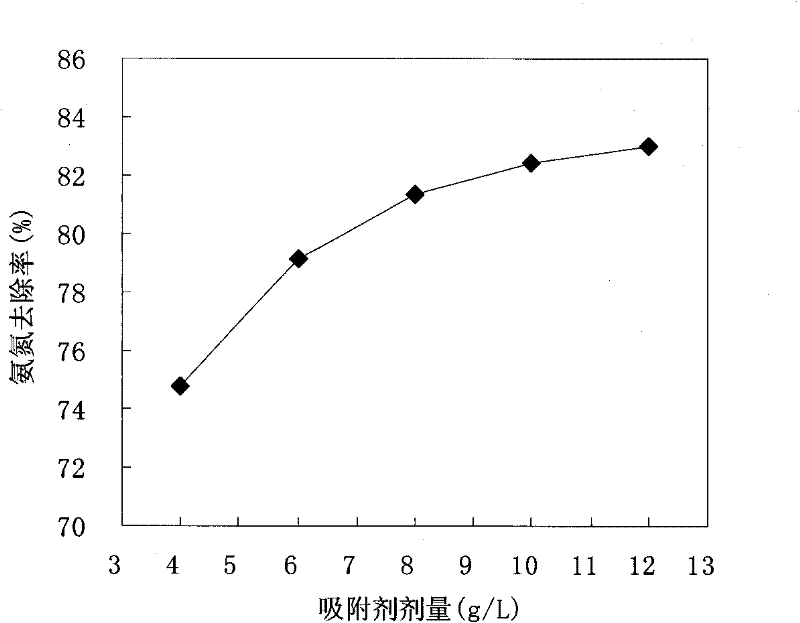

[0019] Strawberry leaves were collected from Jurong Strawberry Garden in Jiangsu Province, washed three times with tap water to remove dust and soluble impurities on the leaf surface, and then dried indoors in the shade to remove water droplets on the leaf surface. The strawberry leaf after drying is earlier at 105 DEG C after killing green for 15 minutes, then baked at 70 DEG C for 10 hours to dry. The dried strawberry leaves are mechanically pulverized, and then sieved into 30 meshes with a standard sieve. Add the prepared adsorbent at a dose of 4g / L to an aqueous solution containing 25mg / L of ammonia nitrogen, shake at room temperature at 250r / min, and shake for 24 hours. The results show that the removal rate of ammonia nitrogen in this state is 74.8%. Under the same conditions, changing the dosage of adsorbent to 6, 8, 10 and 12g / L respectively, the obtained removal rates were 79.1%, 81.3%, 82.4% and 83.0%, respectively.

[0020] It can be seen that within the dosage of...

Embodiment 3

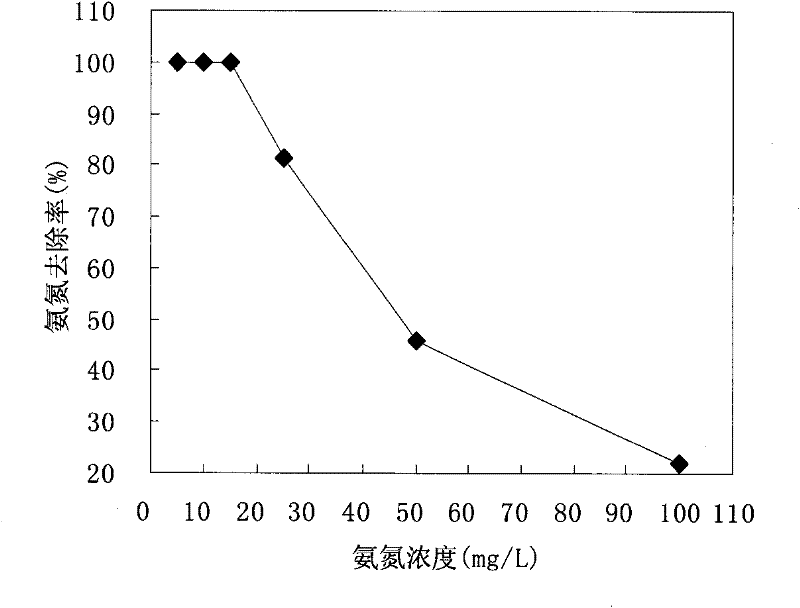

[0022] Strawberry leaves were collected from Jurong Strawberry Garden in Jiangsu Province, washed three times with tap water to remove dust and soluble impurities on the leaf surface, and then dried indoors in the shade to remove water droplets on the leaf surface. The strawberry leaf after drying is earlier at 105 DEG C after killing green for 15 minutes, then baked at 70 DEG C for 10 hours to dry. The dried strawberry leaves are mechanically pulverized, and then sieved into 30 meshes with a standard sieve. Add the prepared adsorbent at a dose of 8g / L to an aqueous solution containing 5mg / L of ammonia nitrogen, shake at room temperature at 250r / min, and shake for 24 hours. The results show that the removal rate of ammonia nitrogen in this state is 100%. Under the same conditions, the ammonia nitrogen content in the solution was changed to 10, 15, 25, 50 and 100 mg / L respectively, and the resulting removal rates were 100%, 100%, 81.5%, 45.9% and 22.0%, respectively.

[0023]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com