Lucid ganoderma spirulina tablet and preparation process thereof

A technology of spirulina tablets and spirulina powder, which is applied in the field of Ganoderma lucidum spirulina tablets and its preparation technology, can solve the problems of difficult to make tablet health products, processing methods and complex preparation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

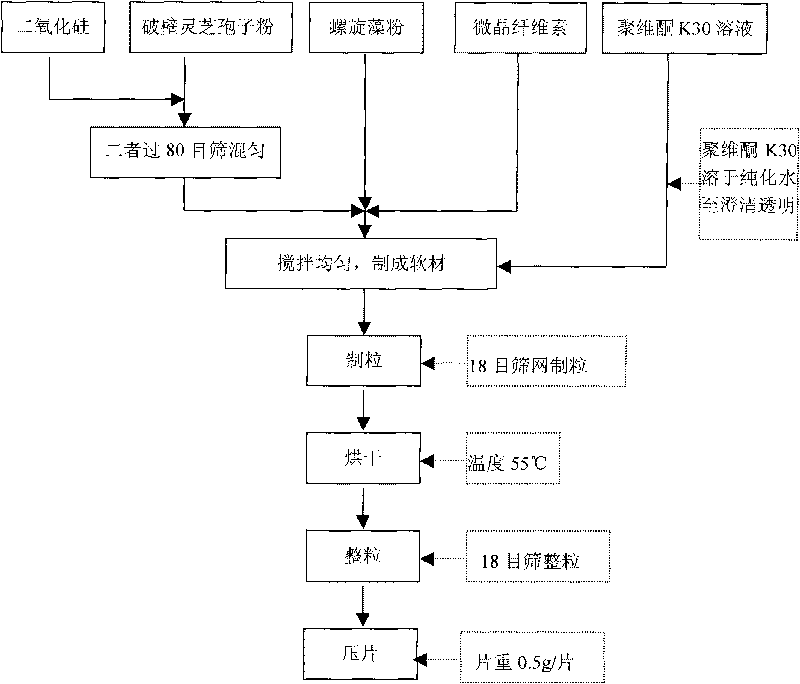

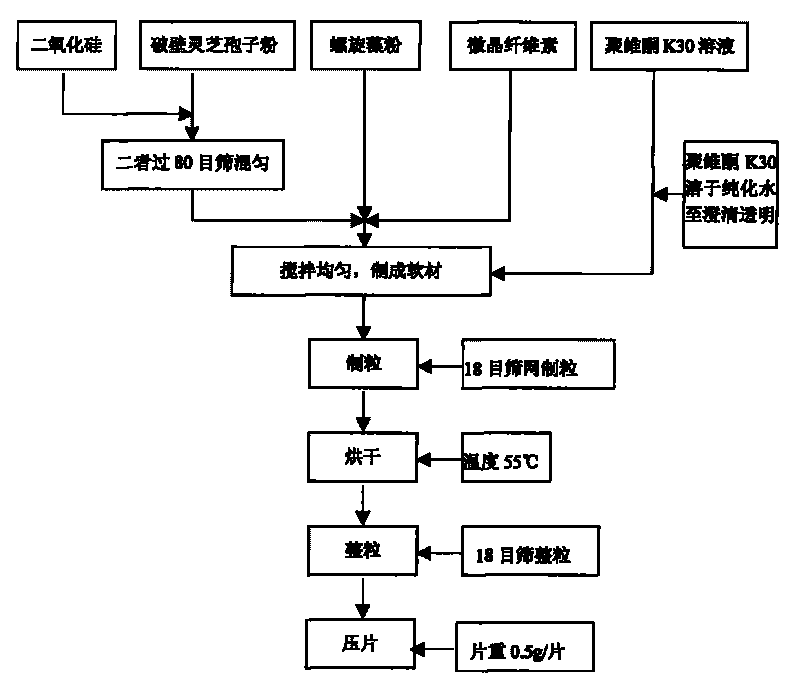

Image

Examples

Embodiment 1

[0025] Take by weighing 150g of broken ganoderma spore powder and 25g of silicon dioxide with a wall-breaking rate of more than 90%, mix, pass through an 80-mesh sieve, put in a tank mixer and mix evenly, then add 175g of spirulina powder and 100g of microcrystalline cellulose, Stir and mix evenly, add 200g of 25% povidone K30 solution (containing 50g of povidone K30 dry matter) to the above-mentioned materials, stir evenly, and make soft material. Put the soft material into a oscillating granulator equipped with a 18-mesh screen to make wet granules, dry them in a hot air circulation oven, granulate, and use a ZP-35 high-speed rotary tablet press for tableting, with a tablet weight of 0.5g / piece.

Embodiment 2

[0027] Take by weighing 100g of ganoderma lucidum spore powder and 20g of silicon dioxide with a wall-breaking rate of more than 90%, mix, pass through an 80-mesh sieve, put in a tank mixer and mix evenly, then add 250g of spirulina powder and 90g of microcrystalline cellulose, Stir and mix evenly, add 200g of 20% povidone K30 solution (containing 40g of povidone K30 dry matter) to the above materials, stir evenly, and make soft material. Put the soft material into a oscillating granulator equipped with a 18-mesh screen to make wet granules, dry them in a hot air circulation oven, granulate, and use a ZP-35 high-speed rotary tablet press for tableting, with a tablet weight of 0.5g / piece.

Embodiment 3

[0029] Take by weighing 50 g of broken ganoderma spore powder and 10 g of silicon dioxide with a wall-breaking rate of more than 90%, mix them, pass through an 80-mesh sieve, and mix evenly in a tank mixer, then add 375 g of spirulina powder and 50 g of microcrystalline cellulose, Stir and mix, add 200g of 7.5% povidone K30 solution (containing 15g of povidone K30 dry matter) to the above material, stir evenly, and make soft material. Put the soft material into the oscillating granulator equipped with 18-mesh screen to make wet granules, dry them in a hot air circulation oven, granulate, and use the ZP-35 high-speed rotary tablet press to compress the tablets, with a tablet weight of 0.5g / piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com