Housing and method for making same

A manufacturing method and shell technology, which are applied in chemical instruments and methods, electrical equipment shells/cabinets/drawers, decorative arts, etc., can solve the problem of single visual effect, weak decoration, difficulty in increasing the added value of products and attracting consumers. eyeball and other problems, to achieve the effect of good wear resistance, increased added value, strong corrosion resistance and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

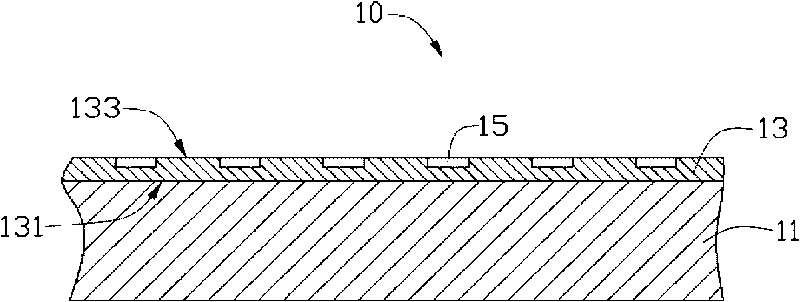

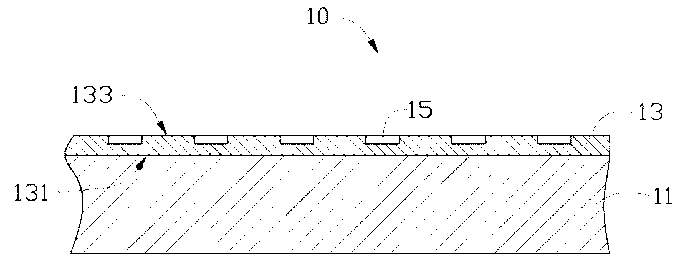

[0013] see figure 1 As shown, the casing 10 of the preferred embodiment of the present invention includes a metal base 11 and a micro-arc oxidation film layer 13 formed on the metal base 11 .

[0014] The material of the metal base 11 can be any one of aluminum, aluminum alloy, magnesium, magnesium alloy, titanium and titanium alloy.

[0015] The micro-arc oxidation film layer 13 includes a first surface 131 and a second surface 133 opposite to the first surface 131 , and the first surface 131 is combined with the metal base 11 . Part or all of the second surface 133 exhibits a mirror effect, which can be formed by polishing the second surface 133 . The polishing method can be mechanical polishing. A groove 15 is formed in the region where the second surface 133 presents a mirror effect, and the groove 15 is in the shape of a pattern, and the pattern can be a product's trademark or symbolic pattern, or other patterns with decorative effects. The groove 15 can be formed by l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com