Precision-location stepping motor for micro-stepping instrument

A technology of precise positioning and stepping motors, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of increasing hardware overhead costs, etc., and achieve the effects of improving operating resolution, strong magnetic field strength, and improving dynamic operating characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

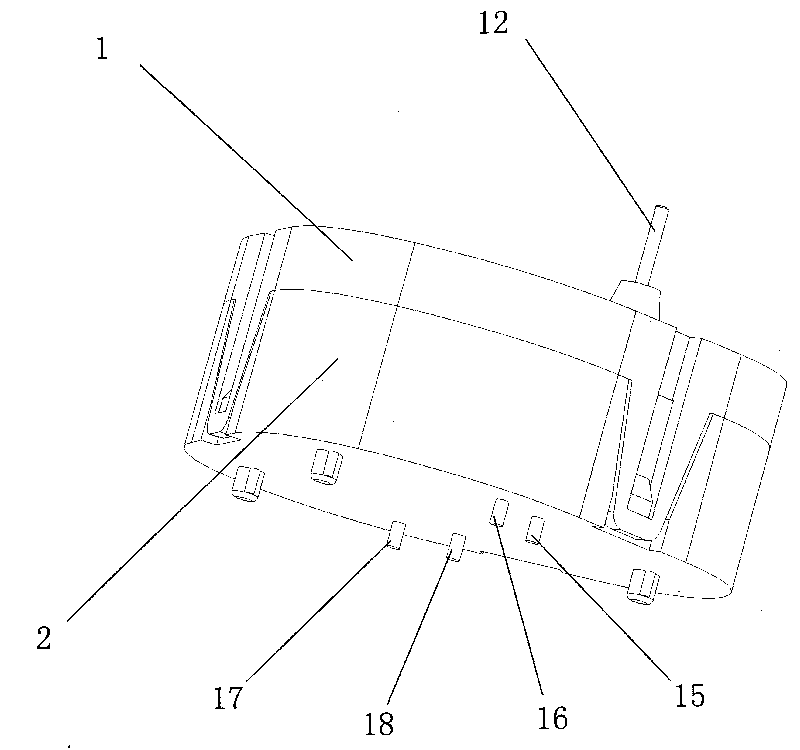

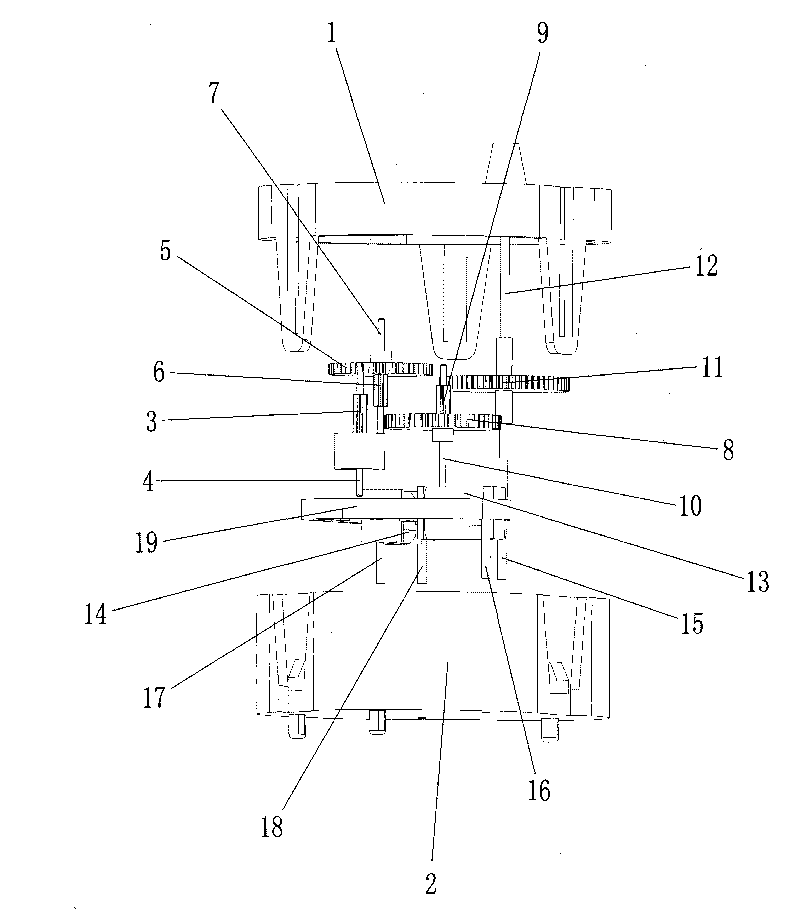

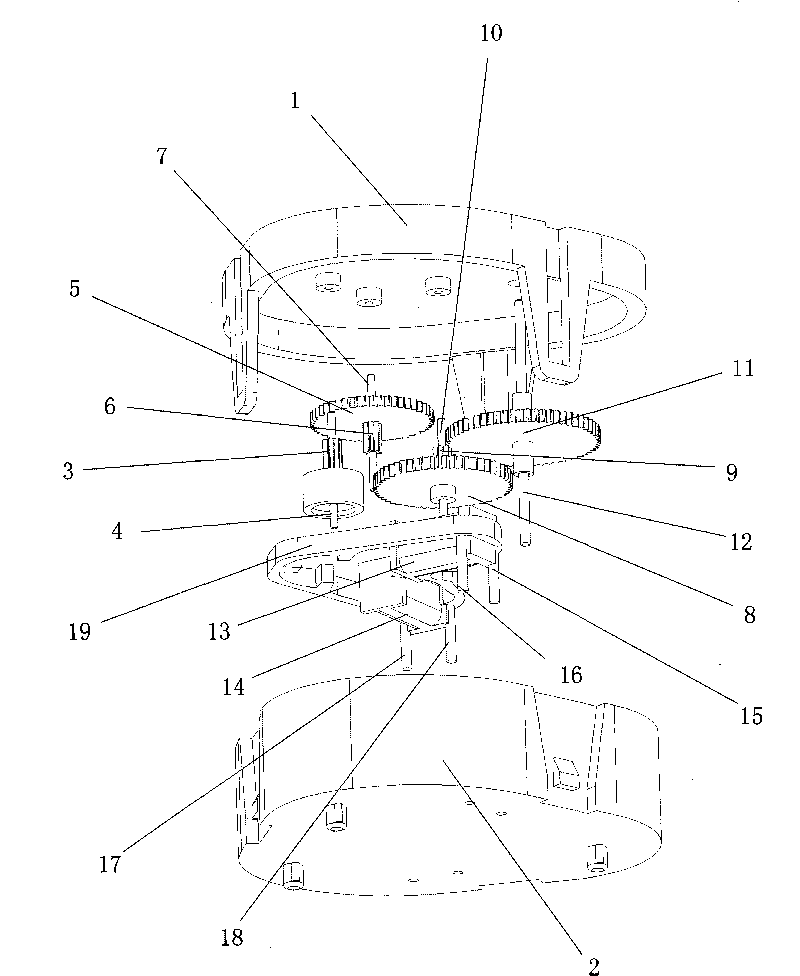

[0038] The invention of the stepping motor comprises a motor casing upper cover (1), a motor casing lower cover (2), a permanent magnet rotor (3), a rotor shaft (4), a first-stage transmission gear set driven wheel (5), and a second-stage transmission gear Group driving wheel (6), I stage transmission gear set driven wheel rotating shaft (7), II stage transmission gear set driven wheel (8), III stage transmission gear set driving wheel (9), II stage transmission gear set driven wheel rotating shaft ( 10), III stage transmission gear set driven wheel (11), pointer drive shaft (12), excitation winding coil XA (13), excitation winding coil XB (14), coil pin A (15), coil pin B ( 16), coil pin C (17), coil pin D (18), stator core body (19).

[0039] figure 1 , 2, the housing cover (1) and the lower housing cover (2) of the motor adopt a lifting and buckling assembly structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com